Strengths

An easy-to-understand introduction to Yokohama Rubber for individual investors.

Technological strengths have generated long list of achievements

Technical excellence recognized by the world’s makers of premium cars

The technical excellence of our tires is demonstrated by their use as original equipment for premium cars manufactured by the world’s leading automobile makers, starting of course with Japanese makers but also including Porsche, Mercedes Benz, BMW, Audi, and others.

YOKOHAMA’s ADVAN Sport V107 is the tire on many of the world’s premium car models.

Supporter of world’s top motor sports events

YOKOHAMA tires are the control tires for many of the world’s leading race series, including the Japanese SUPER FORMULA Championship, Asia’s ultimate Formula racing series. We also support many teams participating in SUPER GT races.

Strong track record in marine products and hydraulic hoses

The outstanding quality and high performance of Yokohama Rubber’s pneumatic fenders contributed to the establishment of the international ISO standard for these products. In addition, we have developed hydraulic hoses for automobiles and construction machinery that meet strict standards in the US and Europe.

World’s largest floating fender

Car air-conditioner hose compatible with next-generation refrigerant

High share in the specialty tire market

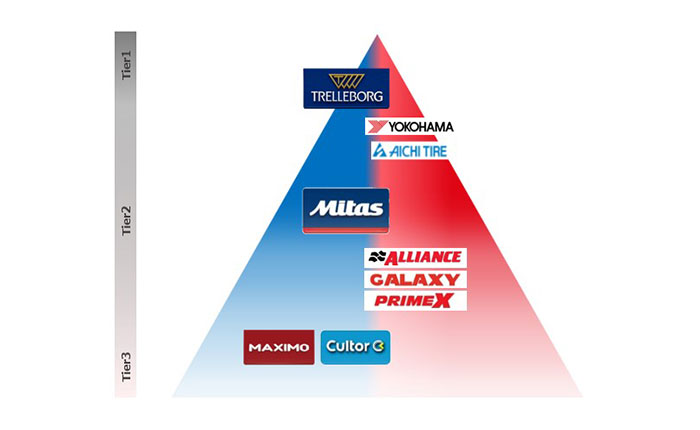

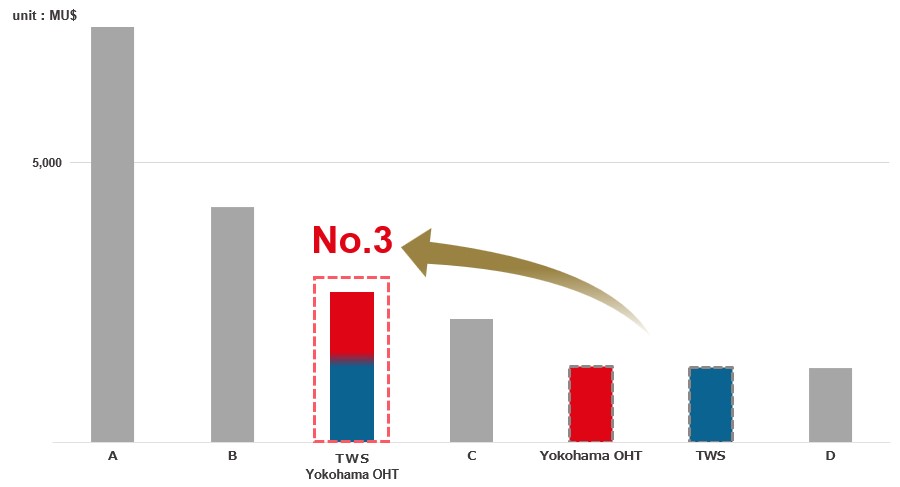

Specialty tires, such as off-highway tires (OHT) for agricultural machinery, industrial machinery and construction machinery, are based on particularly advanced technologies and therefore are manufactured by only a few tire makers. In 2016, Yokohama Rubber entered the market for tires used on agricultural and forestry machinery when it acquired the Alliance Tire Group (ATG). In 2017, we expanded our lineup of industrial machinery tires by acquiring Aichi Tire Industry. The acquisition of Trelleborg Wheel Systems (TWS) in 2023 expanded our OHT brand portfolio, giving us brands in all three tiers of the OHT market and elevating our position in the global OHT market.* We will leverage our strong position in this market to gain a competitive advantage and accelerate the further strengthening of our commercial tire business, which also includes tires for trucks and buses.

*Based on Yokohama Rubber estimates for 2022

R&D system provides timely creation of new products that meet market needs

*including contracted facilities

We have established regional R&D centers that are able to grasp local market needs and quickly develop products that meet local needs. Today, we have tire R&D centers in Japan, Thailand, China and the United States and four comprehensive tire test courses in Japan (2), Thailand, and Sweden.

Extensive global network

Yokohama Rubber has an extensive global manufacturing network with 11 plants in Japan (tires: 8, MB: 3) and 36 overseas plants (tires: 27, MB: 8, natural rubber processing: 1).