Fair Operating Practices

Supplier Environmental Assessment

KPI

Move the screen to the left or right to see the table information

| Item | FY 2021 results | FY 2022 results |

|---|---|---|

| Ratio of new suppliers that business was commenced with after conducting an environmental impact assessment | (Consolidated) 100% (46 companies) | (Consolidated) 100% (58 companies) |

| Negative impacts in the supply chain and actions taken | Zero We distribute our Green Procurement Guidelines when starting up business dealings and only initiate transactions after the supplier understands these guidelines. |

Zero We distribute our Green Procurement Guidelines when starting up business dealings and only initiate transactions after the supplier understands these guidelines. |

Responsible Departments

Raw Materials Procurement Department, Indirect Materials Procurement Department, Procurement Division

Our position and Targets

Why is “Supplier Environmental Assessment” a critical issue to be addressed?

Explanation of the reason and background

The raw materials used in the major products of the Yokohama Rubber Group contain many petrochemical products (chemicals) including various types of synthetic rubber that can cause environmental pollution and have a negative impact on the lives of local residents during the manufacturing process. Because the worst case can lead to suspension of operations at suppliers, we have selected environmental impact assessments of suppliers as a critical issue to be addressed from both the perspective of the stable procurement of raw materials and the perspective of ethics.

Environmental impact assessment at the start of new business relationships

When adopting new raw materials, it is confirmed whether the materials comply with various regulations, and suppliers are asked to submit documents to serve as evidence of compliance.

- Quality control survey form

- Raw materials standards

- Shipped materials inspection report

- Safety data sheet (SDS*1) (the applicable raw materials are chemicals that include rubber compounding agents that SDS is applied to)

- Specific toxic chemical substances survey form

- Declaration of Non-inclusion of Substances Prohibited by the European ELV Directive and Other Prohibited Substances*2

- Data certifying non-inclusion of substances banned under the European ELV Directive and others*2

- Four heavy metal substances survey form

In addition, we have issued the Green Procurement Guidelines that indicates the Green Procurement Policy of the Yokohama Rubber Group and our requests to suppliers in order to gain an understanding of these matters.

- 1 SDS: Safety data sheets are international standard-forms to provide information on the characteristics and handling of chemicals when transferring or providing chemical substances or products (chemicals) that contain them.

- 2 EU ELV Directive: An EU directive aimed at reducing the impact of end of life vehicles (ELV) on the environment.

Assessment of environmental impact in the supply chain

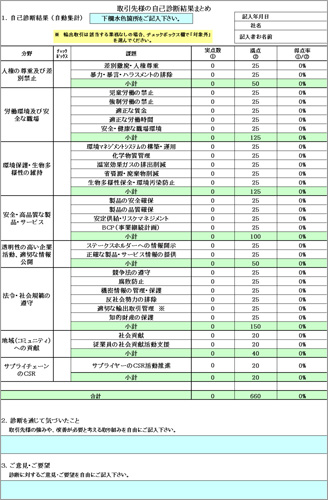

We ask suppliers to conduct a CSR self-check based on the "Material Purchasing Selection Guidelines" that includes a self-assessment report on management matters including the state of acquired certification for environmental management systems (ISO14001), substances of concern, and greenhouse gases. We revised the check sheet to further boost results in 2017, and continued conducting surveys in FY2022.

<CSR self-check sheet>

Countermeasures in response to suppliers found to have a significant impact on the environment

While there have not been any such cases up until now, in such a case we will hold direct discussions with supplier plants on improvement points, causes, and improvement measures, and then implement these measures. We will suspend transactions in cases where improvements are not seen after that, or malicious cases such as false reports are recognized.

Vision and targets

We started assessments with the new check sheet from 2017, and conducted self-check investigations of suppliers of main raw materials. Based on the results, we asked several suppliers to participate in workshops and carried out activities to deepen their understanding regarding CSR.

In the future, we will carry out self-check investigations of overseas suppliers and expand our activities.

In the future, we will carry out self-check investigations of overseas suppliers and expand our activities.

Measures to pursue our vision

Study meetings have been held for the procurement representatives at domestic and overseas business locations of the Yokohama Rubber Group, and will be continued in the future, including the improvement of those activities.

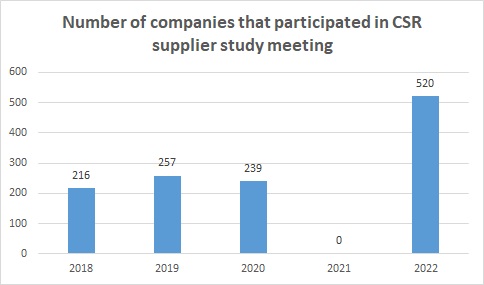

With the advances in IT and other systems, we held internal discussions and preparations for holding CSR Supplier Study Meetings remotely that had been held face-to-face and in written-format in the past, with meetings made available from FY2022.

In fiscal 2022, we held Suppliers’ Day for suppliers of natural rubber to call for their cooperation in CSR after explaining the sustainable natural rubber procurement policy. Additionally, we are now preparing to roll out a similar activity also for all other suppliers.

Y.T. Rubber Co,. Ltd. (YTRC) of Thailand includes in basic trading contracts clauses on compliance including environmental protection and human rights, in an effort to promote CSR at natural rubber plantations.

Objectives related to sustainable procurement have been incorporated as performance evaluations with the Procurement Division.

With the advances in IT and other systems, we held internal discussions and preparations for holding CSR Supplier Study Meetings remotely that had been held face-to-face and in written-format in the past, with meetings made available from FY2022.

In fiscal 2022, we held Suppliers’ Day for suppliers of natural rubber to call for their cooperation in CSR after explaining the sustainable natural rubber procurement policy. Additionally, we are now preparing to roll out a similar activity also for all other suppliers.

Y.T. Rubber Co,. Ltd. (YTRC) of Thailand includes in basic trading contracts clauses on compliance including environmental protection and human rights, in an effort to promote CSR at natural rubber plantations.

Objectives related to sustainable procurement have been incorporated as performance evaluations with the Procurement Division.

Review of FY 2022 Activities

- Among all 58 new suppliers in Japan, there were no suppliers that caused an environmental impact.

- CSR Supplier Study Meetings were held in an online format by the Procurement Division four times in the spring of 2022, with 520 companies taking part.

- All members of the procurement department took compliance training courses (100%).

Number of companies that participated in CSR supplier study meeting

- Target companies: Companies that fall under items in our regulations

- Conducted: Confirmed in writing in FY2020, and will not be held in FY2021

Green procurement

Yokohama Rubber has been working on the development and usage of raw materials to contribute to the environment through the cooperation of our business partners with preservation of forest resources, control of global warming, usage of recycled raw materials, and expansion of non-petroleum raw materials as the main themes.

Furthermore, we manage parts procurement based on the "Yokohama Green Procurement Guidelines." We ask that all suppliers confirm whether products contain SOCs (substances of concern) and ask that they submit a statement of non-use.

We began participating in SNR-i activities that aim for the sustainable economics of natural rubber advocated by the International Rubber Study Group (IRSG) from 2017.

In 2018, Yokohama Rubber joined the Platform for Sustainable Natural Rubber (GPSNR), which was established by the Tire Industry Project (TIP) of the World Business Council for Sustainable Development (WBCSD) as a founding member.

We began working on reporting member information (Reporting Requirements) from FY2022, and raised transparency of shared information.

We are also discussing with other member companies methods for enhancing traceability of suppliers.

Furthermore, we manage parts procurement based on the "Yokohama Green Procurement Guidelines." We ask that all suppliers confirm whether products contain SOCs (substances of concern) and ask that they submit a statement of non-use.

We began participating in SNR-i activities that aim for the sustainable economics of natural rubber advocated by the International Rubber Study Group (IRSG) from 2017.

In 2018, Yokohama Rubber joined the Platform for Sustainable Natural Rubber (GPSNR), which was established by the Tire Industry Project (TIP) of the World Business Council for Sustainable Development (WBCSD) as a founding member.

We began working on reporting member information (Reporting Requirements) from FY2022, and raised transparency of shared information.

We are also discussing with other member companies methods for enhancing traceability of suppliers.

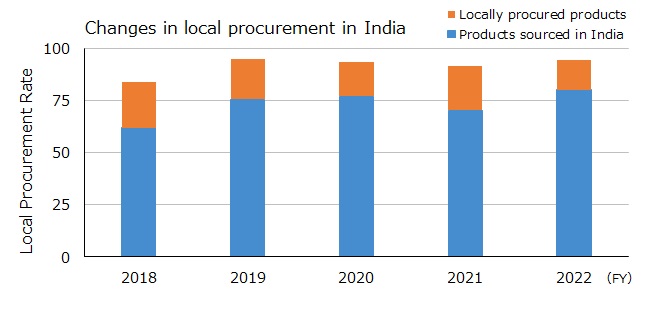

Reductions in CO2 emissions from shipment (promotion of local procurement adoption)

Following on from North America, we were able to switch from raw materials important from Japan to local procured goods at plants in China. We were also advancing with the adoption of local procured raw materials at plants in countries like India.

<Changes in local procurement in India>

Yokohama Green Procurement Guidelines

With the management of chemical substances contained in products as a form of entrance control, we ask that suppliers work towards environmental preservation and manage procurement items in accordance with our Green Procurement Guidelines. We also confirm that prohibited substances in international agreements such as the European ELV Directive, the revised RoHS (RoHS2) Directive, and REACH regulations are not included.

Furthermore, based on our "Green Procurement Policy," we purchase raw materials, outsourced items, and subsidiary materials in accordance with environmental footprint standards.

Furthermore, based on our "Green Procurement Policy," we purchase raw materials, outsourced items, and subsidiary materials in accordance with environmental footprint standards.

Expansion of agroforestry plantations in Thailand

Y.T. Rubber Co., Ltd. (YTRC), a natural rubber processing company located in Thailand, supports the agroforestry plantation methods advocated by Professor Sara of Songkla University. YTRC is expanding initiatives to introduce this method to rubber plantations owned by neighboring farmers and the families of employees to validate its effectiveness.

Agroforestry is a coined term from the words agriculture and forestry, referring to grazing livestock and cultivating crops between planted trees.

Actions for Sustainable Natural Rubber Procurement

Agroforestry is a coined term from the words agriculture and forestry, referring to grazing livestock and cultivating crops between planted trees.

Expected benefits of agroforestry

Harvesting multiple types of crops such as fruits, herbs and wood in a natural rubber forest has many advantages, including a stable income and increased biodiversity in plantations. In particular, natural rubber is only produced for about 20 to 25 years after planting trees, after which the production progressively declines. This makes replanting necessary to ensure efficient production. However, para rubber trees do not produce natural rubber for five to six years after they are planted. Due to the loss of income during this period, rubber farmers may delay replanting or abandon their natural rubber business. Agroforestry is also an effective means for them to produce natural rubber in a sustainable manner. In addition to providing a supplemental income when para rubber tree saplings are too young to produce latex, agroforestry provides the following benefits.

Natural rubber prices fluctuate greatly with the market. Even after natural rubber is ready to be harvested, various crops planted in the plantation will help to stabilize the income of natural rubber farmers.

Rubber trees experience a period called “wintering” every year, when the leaves of all rubber trees fall off at the same time before new leaves start to grow. Since rubber trees drop few leaves at other times of the year, so once the leaves that fell off during the wintering period have been decomposed by insects and microorganisms, etc., there is nothing left to cover the soil surface, as the result of which the soil can become gradually drier. However, if a variety of different plants are planted together, the ground surface will always be covered with fallen leaves, which prevents the soil from getting dry. Decomposition fallen leaves also serve as fertilizer for the rubber trees, contributing to the reduction of production costs. One of the diseases affecting rubber trees is called "white root disease (WRD)," the risk from which is considered to be highest in Southeast Asia. Once a rubber tree becomes infected with WRD, the disease can spread to other nearby trees very rapidly, and in the land where this happened, rubber trees cannot be planted for at least five years. Since natural rubber plantations practicing agroforestry are growing a wide variety of different plant species, the range of microorganisms in the soil is much more complex, which is believed to contribute to fostering a WRD-resistant environment.

Another benefit of having multiple types of plants in a rubber plantation instead of practicing monoculture to plant only para rubber trees is that this increases the number of insects and birds that use such plants, which also results in enriched biodiversity.

Rubber trees experience a period called “wintering” every year, when the leaves of all rubber trees fall off at the same time before new leaves start to grow. Since rubber trees drop few leaves at other times of the year, so once the leaves that fell off during the wintering period have been decomposed by insects and microorganisms, etc., there is nothing left to cover the soil surface, as the result of which the soil can become gradually drier. However, if a variety of different plants are planted together, the ground surface will always be covered with fallen leaves, which prevents the soil from getting dry. Decomposition fallen leaves also serve as fertilizer for the rubber trees, contributing to the reduction of production costs. One of the diseases affecting rubber trees is called "white root disease (WRD)," the risk from which is considered to be highest in Southeast Asia. Once a rubber tree becomes infected with WRD, the disease can spread to other nearby trees very rapidly, and in the land where this happened, rubber trees cannot be planted for at least five years. Since natural rubber plantations practicing agroforestry are growing a wide variety of different plant species, the range of microorganisms in the soil is much more complex, which is believed to contribute to fostering a WRD-resistant environment.

Another benefit of having multiple types of plants in a rubber plantation instead of practicing monoculture to plant only para rubber trees is that this increases the number of insects and birds that use such plants, which also results in enriched biodiversity.

Natural rubber farm that practicing agroforestry

Professor Sara and the natural rubber farmers

<Theory behind Professor Sara’s agroforestry method>

- The following synergistic effects will be achieved by planting different tree species between the rows of natural rubber trees grown at plantations.

- Other trees will promote the growth of natural rubber trees increasing yield, extending their life, and reducing the amount of chemical fertilizers used

- Products harvested from other trees, such as fruit, bamboo and wood, increases farmer income

- Compared to conventional rubber tree plantations, trees can be maintained in a state that is close to a natural forest

From 2016, YTRC worked together with Professor Sara to provide guidance to and conduct verification on experimental plantations nearby. In addition, YTRC regularly create organic fertilizer and supply it together with seedlings to nearby plantations and government agencies. In FY2022, YTRC provided 10,220 seedlings, supporting a cumulative total of 189 ha and 63 farms.

We are also conducting questionnaire surveys with natural rubber suppliers in Thailand to assess the state of natural rubber farmers and farms and to gather information on CSR activities that are being conducted.

Future challenges

With the expansion of our business, creating a database of supplier information including environmental impact is an urgent task due to the increasing number of suppliers.

In addition, we recognize keeping self-checks by suppliers uniform at a high level as an important issue, and accordingly we identify issues and use them as the main theme of study meetings as we work towards improvements. Furthermore, in order to promptly implement the above, we recognize the need to aim for further improvements in the level of procurement representatives at the domestic and overseas business locations of the Yokohama Rubber Group.

We also analyze the aggregated results of questionnaires with overseas suppliers of natural rubber, and consider counter.

In addition, we recognize keeping self-checks by suppliers uniform at a high level as an important issue, and accordingly we identify issues and use them as the main theme of study meetings as we work towards improvements. Furthermore, in order to promptly implement the above, we recognize the need to aim for further improvements in the level of procurement representatives at the domestic and overseas business locations of the Yokohama Rubber Group.

We also analyze the aggregated results of questionnaires with overseas suppliers of natural rubber, and consider counter.