SC Kingflex Corporation (SCK)

苗栗工場(Miaoli Plant)

中壢工場(Zhongli Plant)

Production and sale of low and high pressure rubber hoses, assembly parts and compound master-batch (CMB) products

Total site area30,464 m2

Number of employees165 (as of May 2023)

LocationZhongli factory: No.99 Xiyuan Rd., Zhongi District, Taoyuan, 320, TAIWAN R.O.C.

Miaoli Factory: No.91 Jungsing Road, Jungsing IND. Park, Tunglo, Miaoli, 36647, TAIWAN R.O.C.

Management and Sales Division, Management Department

Tel: +886-3-451-4015 Fax: +886-3-451-2969

Message from the President

Lin Qingchi (Chairman, right) and Kazuyuki Mineo (President, left)

SC Kingflex Corporation is a Taiwanese company established in 1979 and is celebrating its 42nd anniversary this year. We have produce and sell low and high-pressure rubber hoses, assembly parts and compound master batches. We became a member of the Yokohama Rubber Group as a joint venture with Yokohama Rubber in 1990 and currently operate two plants in Taiwan.

We have made safety and the environment an important pillar of our management, acquiring ISO 14001 certification in 2001 and ISO 45001 certification in 2020. As a member of the local community, we are actively engaged in activities to reduce our environmental impact while ensuring a safe working environment.

As specific activities, in production we have promoted to increase the number of times that the mandrels and vulcanization coating materials (molds) required essential for the production of hoses are recycled. Furthermore, we have increased energy efficiency by improving equipment.

In addition, we base our business operations on "safety," "environment," and "quality," and by acquiring and operating management system certifications in these three areas, we are able to provide earth-friendly products that ensure safety and security for our customers.

We will demonstrate "Caring for the Future", the CSR slogan of Yokohama Rubber's new medium-term management plan YX2023, in our business activities. And we will strive to operate our business in a way that will be recognized by everyone.

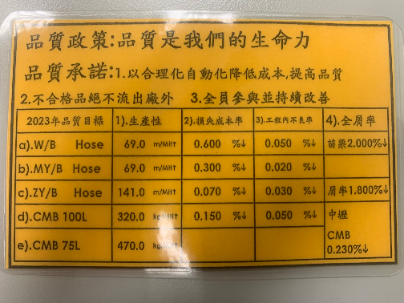

In order to maintain and improve the quality of our products, we set quality targets every year and distribute cards to all employees to raise their awareness.

In 2023, we planted trees for the 6th time at the Miaoli Plant as part of the "Forever Forest" activities.

Tree Planting at Miaoli Plant ( March 15, 2022 )

Organizational Governance

Compliance education

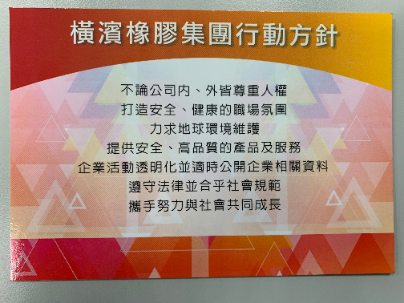

In addition to distributing the SC Kingflex Corporation Management and Conduct Manual to all employees, we have posted our action policy and made our employees thoroughly aware of it. Furthermore, we have also created a Chinese language version of the Yokohama Rubber Group Guide for Conduct and distributed copies to all employees. In 2023, we reviewed and thoroughly implemented our “work implementation based on rules”, based on a work audit by the Yokohama Rubber Co., Ltd. (YRC) audit office and implemented at the end of 2016.

Human Rights

Education on respect for human rights

The company regulations provide for compliance with various laws, including human rights.

Labor Practices

Occupational safety and health

- To carry out occupational accident prevention activities by participation and efforts of all employees.

- To prevent occurrence of occupational accidents by the safety management system.

- To improve in compliance with required regulation targets in accordance with laws.

In 2020, both Miaoli and Zhongli factories have obtained ISO 45001 certification.

Education and training for employees

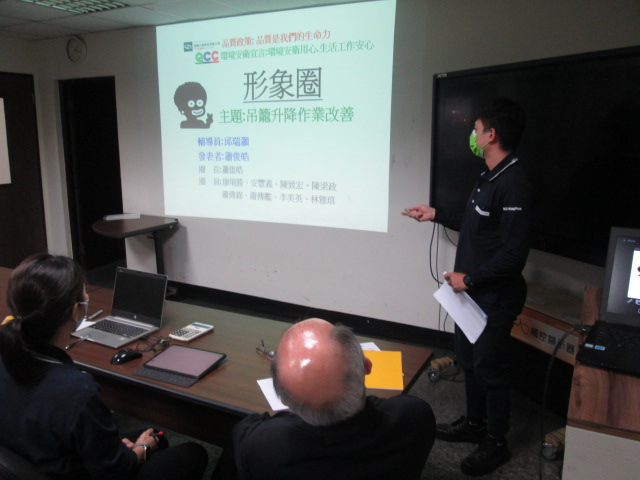

We conduct QCC activities (Quality Control Circle small group improvement activities) and hold a presentation meeting every year.

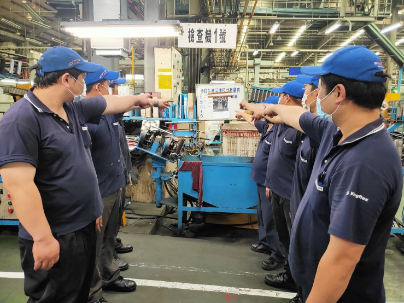

In addition, we regularly conduct KYT training and operational training using forklifts, boilers, and other equipment.

QCC presentation (January 13, 2023)

KYT training

Responses in case of disaster

Twice a year, fire drills and safety drills involving rescue techniques are conducted at both plants, and we also maintain and review our emergency contact network as needed.

In addition, AEDs are always available at both plants, and employees are trained in their use.

Promotion of gender equality

In accordance with the spirit of gender equality, we do not conduct recruitment based on gender.

We have not implemented any special measures to boost recruitment of female employees, but the company does already have a large number of female employees, reflecting the special characteristics of the region where we are located.

Employment of people with disabilities

The current employment rate of disabled people is 0.6%.

The Environment

Environmental management

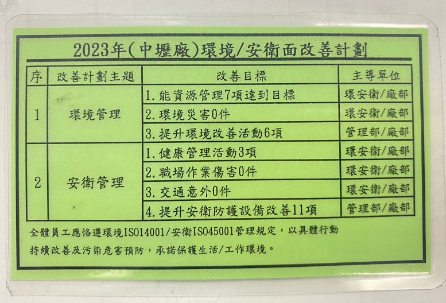

In responding to both the Environment Month and Safety Month run by Yokohama Rubber, we take steps to promote and strengthen the various categories of activity.

Additionally, we set environmental and safety goals every year and distribute cards with these goals to our employees to raise their awareness.

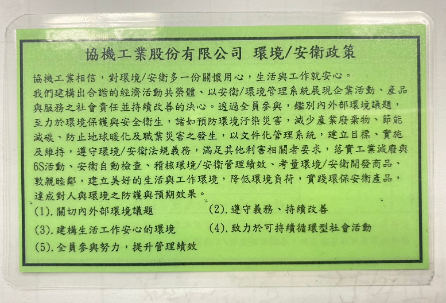

- We will be concerned about internal and external environmental issues.

- We will comply with the rules and make continuous improvement.

- We will build an environment where people can live and work in peace.

- We will engage in sustainable social activities.

- We achieve our improvement goals with the participation of all.

The Environmental Policy is explained at the start of each financial year, and shared with all employees.

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

We filed monthly the status of chemical substances with the Taiwanese Government. We continue to manage chemical substances appropriately.

Noise, vibration and odor

While we have on occasion undergone on-site inspections conducted by the Environmental Protection Administration (EPA) of the Taiwanese Government, we have never been subject to matters of concern being pointed out through these inspections.

Environmental data

Move the screen to the left or right to see the table information

| Category | FY 2018 | FY 2019 | FY 2020 | FY 2021 | FY 2022 | |

|---|---|---|---|---|---|---|

| Waste disposed (t) | 203 | 207 | 159 | 186 | 168 | |

| Proportion sent to landfill (%) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Landfill waste (t) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Energy use (oil equivalent: kl) |

Electric power | 1,095 | 1,005 | 774.5 | 1,066 | 996 |

| Fuel | 214 | 206 | 196.3 | 229 | 221 | |

| Total | 1,309 | 1,211 | 970.8 | 1,295 | 1,217 | |

| Greenhouse gas emissions (1,000t-CO2) | 3.8 | 3.4 | 2.1 | 2.6 | 2.6 | |

| Water usage (1,000m3) | 12.2 | 11.3 | 10.3 | 10.6 | 9.1 | |

- FY: January to December

- Greenhouse gas emissions were calculated based on the Greenhouse Gas Protocol Initiative since FY2015.

- We calculate the volume of greenhouse gas emissions each year.

- We create a monthly energy and water usage and waste reduction plan and manage the progress every month. Whereby anomalies occur within these results, we identify their causes and implement responses.

- We changed the boiler fuel from fuel oil to gas in 2019.

Fair Operating Practices

Corruption prevention

We strictly comply with all laws, practices and social ethics.

Involvement in supplier management

We strive to provide, contract, and manage the adoption preparations for configuring relationships with suppliers based on the Yokohama Rubber Co., Ltd. platform.

Requests and opinions to Yokohama Rubber from suppliers

We have a system in place that allows for opinions to be received through agents.

Consumer Issues

Communication with customers

We maintain a website with a corporate profile and overview of our products. Furthermore, customer satisfaction surveys are conducted twice a year in order to improve products and services.

Responses to complaints

In order to promptly respond to customer requests, we have established a quality assurance policy and we adhere to it.

Relationship with local societies

Every January, all employees clean the road from the Zhongli plant to the mausoleum in the industrial park and the area around the Miaoli plant. We also clean up the road in front of the Zhongli Plant every Monday.

Cleanup Activities around Zhongli Plant (January 3, 2022)

Cleanup Activities around Miaoli Plant (January 3, 2022)

Once a year since fiscal 2009, employees of Zhongli and Miaoli plants have participated in a beach cleanup activity each time. These events are regional beautification activities sponsored by Miaoli County.

The event was not held in 2022 due to COVID-19.