Nagano Plant (GP)

Production of hydraulic-hose fitting and auto-hose fitting parts, and the production of self-sealing assemblies, coupling assemblies, hydraulic-hose assemblies, and auto-hose assemblies

Total site area28,169 m2

Number of employees352 (as of June 2023)

Location9100 Kawano, Toyooka-mura, Shimoina-gun, Nagano 399-3201, JAPAN

Nagano Plant (Takamori)

19,809 m2

Location548 Yoshida, Takamori-cho, Shimoina-gun, Nagano 399-3102, JAPAN

*Production operations ceased in late June 2017.

Plant Control Section

Tel: +81-265-34-2051 Fax: +81-265-34-2052

E-mail: akihiko.sugeta @y-yokohama.com

Message from the General Manager

Eita Minegishi

The Nagano Plant began operations in the town of Takamori in 1961.

In 2013, we began implementation of a plan to integrate the metal fittings processing and hose assembly operations of the Hoses and Couplings Division. The first stage in this project was the relocation of the functions of the Hiratsuka-Higashi plant (in Kanagawa Prefecture) to a new factory built in Toyooka Village; this relocation was completed in February 2014.

In 2015, work began on the construction of a new factory on an adjacent site; and this was completed in November 2016. We then proceeded to move the functions of the Takamori Plant to the new factory, the relocation of major production facilities was completed in June 2017, and this marked a major new step forward for us with the development of integrated production, including everything from metal fittings processing through to hose assembly.

Through machining and cutting processes that make use of equipment such as multi-axis CNC machines and NC lathes, etc., we produce oil pressure hose clasps and hose clasps for automobiles; we also complete the production of hoses produced at the Ibaraki Plant by caulking and assembling them. These products are then supplied to various hosepipe markets such as the construction machinery, machine tools and automobile manufacturing industries.

Besides being used for assembly in our own factory, the clasps that we manufacture are also supplied to affiliated plants in Japan and overseas and to other domestic customers nationwide. Furthermore, we don’t just engage in the cutting of clasps, we also undertake the assembly of self-seal couplings.

The Nagano factory is located on the east bank of the Tenryu River, in the Ina Valley with its beautiful natural scenery, bordered by the Southern Alps (Akaishi Range) and the Central Alps (Kiso Range).

Precisely because of our location in such a marvelous natural environment, we are determined to keep the burden that we place on the environment as small as possible, and we are implementing various measures aimed at combatting global warming and at contributing to the development of a recycling-based, low-carbon society through energy conservation, resource-saving and recycling.

As regards energy-saving, in addition to promoting familiar energy-saving activities both at the plant and in the homes of all employees by acting as one, by introducing and renewing power saving-type equipment within the plant and seeking to control the wasteful use of energy, we are actively striving to help prevent global warming.

With regard to community and CSR activities, since fiscal 2013 we have been undertaking biodiversity conservation work involving surveys of the flora, aquatic fauna and birds along the Oshima and Tenryu Rivers. Such activities will help in conservation.

On September 7, 2015, thanks to assistance provided by Nagano Prefectural Government, we signed a “Forest Stewardship Agreement” with Toyooka Village and began to undertake satoyama (traditional community-managed forest) conservation work with respect to the area around the Toyooka Village Gymnasium and Sports Ground. In 2016, our efforts in these activities received recognition in the awarding of the Shimoina Forest Association Chairman’s Prize in the Minami Shinshu Healthy Forests Awards.

Concerning the “Yokohama Forever Forest Project” that has continued since 2007, we concluded the plan for stage VI tree planting activities in 2013, and in 2016 we donated a total of 1,040 seedlings grown at the plant to local towns and villages.

For the Tenryu River which flows through the region, each year we proactively participate as a party in charge of allocations during the river cleanup (the environment picnic).

We also make effective use of opportunities for communication and exchange with the residents of Takamori and Toyooka, for example by arranging plant tours for local elementary and high school students and members of local organizations, etc. In addition to listening to what people have to say, we are working to improve understanding of the Company’s business activities and its environmental conservation efforts.

Furthermore, by visiting the suppliers who collaborate with us on the provision of materials and parts for our business, and by proactively encouraging our customers to visit us, we foster smooth, two-way communication, in line with our aim of being a factory that is able to respond effectively to every nuance of market needs within the supply chain.

Organizational Governance

Concerning decision-making, a system is in place so that monthly meetings are held for each different area. Safety and health issues are decided by the Safety and Health Committee, environment issues by the Environment Committee, energy issues by the Energy Savings Committee, and quality issues by the Quality Committee. Furthermore, Section Chief Meetings and Follow-up Meetings are held as required to make decisions on plant-wide issues. Employees are notified of the decisions made by this committee system through daily communications and by the General Manager’s Morning Meeting held at the start of each month.

As regards compliance awareness-raising activities, at the end of each monthly Safety and Health Committee meeting, the Safety and Health Section Chief (who also serves as head of the Corporate Compliance Department) uses the Department’s “Workplace Learning Session Materials” to implement education for the meeting participants. In each workplace, the members of the Safety and Health Committee implement the activities decided on at the workplace safety and health committee meetings on a plant-wide basis.

Human Rights

Supply chain relations

We were unable to visit each company from which we procure parts and materials in FY2022 due to the COVID-19 disaster.

In FY2023, we will visit each company systematically to confirm production and quality status based on the "3 Gen" principle of " actual place," "actual part," and " actual situation" in order to achieve a better image through collaboration.

We also aim to foster effective communication with suppliers through the holding of Purchasing Liaison Meetings, Supplier Quality Coordination Meetings, and CSR Study Meetings.

Regarding our customers, by attending certified plant management meetings and hosting plant inspections, we are able to assist customers with their business operations by maintaining a clear picture of the types of products and services that our customers, and the market as a whole, require.

Labor Practices

Nagano Plant Safety and Health Policy

Following the Management Policy “Create a workplace that values, improves and energizes people,” Yokohama Rubber shall consider the safety and health to be the basis for everything, and focus on preventing occupational accidents and creating workplaces comfortable and healthy both physically and mentally.

Health and Safety Policy- Giving top priority to the safety and health, participating by all members and developing globally, whole Yokohama Rubber group will improve the safety and health activities.

- Yokohama Rubber will comply with all laws and regulations related to the safety and health, and take continuous improvement for the safety and health.

- Yokohama Rubber will communicate with stake holders and cooperate with value chains to contribute to the local communities and the society.

- Yokohama Rubber will strengthen the use of the Occupational Safety and Health Management System and repeat the PDCA cycle for continuous improvement.

- Yokohama Rubber will carry out Risk Assessments for the “safety of the equipment” and “establishment of the Standard Operating Procedure” to promote reduction of the risk.

- Being a part of the automotive industry, Yokohama Rubber will take preventive measures against traffic accidents.

- Yokohama Rubber will create the safe and comfortable workplace, and take measures to promote physical and mental health positively.

- Yokohama Rubber will make employees recognize the importance of the safety and the health, and provide education and training for them as required.

- Yokohama Rubber shall publish this policy and make it known to all.

January 1, 2023

Nagano Plant,Yokohama Rubber Co., Ltd.

General Manager

Eita Minegishi

Disaster-prevention drills

Emergency drills were held on June 22 and 27 in the spring and November 9 and 16 in the fall. Self-defense firefighting drills were also held in conjunction with these drills.

Water fire extinguisher training was also conducted for employees. The training was designed to ensure that employees are trained in the use of fire extinguishers and are able to quickly extinguish fires.

Evacuation Drill

Evacuation Drill

Formation of each team

Assumed power outage drill

Firefighting training with water

Fire extinguisher training with water

The Environment

Nagano Plant environmental policy

Following the norm of "valuing fairness to society and harmony with the environment" as stated in our management policy, we will become a top-level environmentally friendly business site that embodies "caring for the future" for the sake of the global environment.

- Under the leadership of senior management, the Nagano Plant, as an integrated clasp-processing and assembly operation, works on reducing environmental impacts at all stages on a global level, from production to waste recycling/handling, by implementing world-acclaimed environmental activities that are uniform through the Group.

- In order to remain a plant that is trusted by society, we strive continuously to prevent environmental pollution and sensory pollution and to reduce environmental impact through chemical substance management in our effort to improve the environment. We achieve this by strengthening our environmental management systems and adopting a proactive stance in an aim for zero environmental risks.

- To achieve carbon neutrality, we will promote decarbonization measures such as energy-saving activities and introduction of renewable energy. We will also promote resource conservation and recycling to realize a recycling-oriented society.

- We observe the environment-related laws and regulations applicable to the plant, and other agreements which we have entered into, and we continue to implement measures aimed at furthering environmental protection.

- We work to promote cooperation with the value chain and to contribute to both the local community and society as a whole. While doing so, we shall respect international regulations and deepen our communication with stakeholders.

- We have set out environmental objectives and targets to realize the environmental policy of the plant, and we prepare and implement plans accordingly.

- We maintain communications with the local community, and promote activities in harmony with the region that also make a positive contribution to the region.

- We will strive to conserve biological diversity irreplaceable in the region and use natural resources in a sustainable manner in our business activities.

- To improve their own understanding, awareness, and actions, we educate and enlighten all our employees and individuals so that they fully understand this environmental policy.

- Our environmental policy shall be made available to the public upon request.

January 1, 2023

Nagano Plant,Yokohama Rubber Co., Ltd.

General Manager

Eita Minegishi

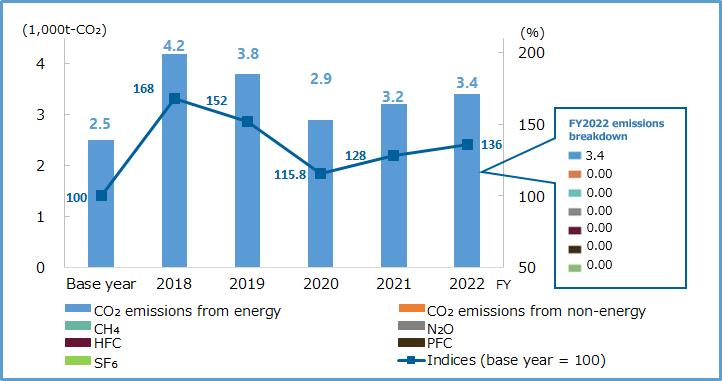

Environmental data (Nagano Plant)

Reductions in greenhouse gas emissions

Greenhouse gas emissions at Nagano Plant and their indices (base year = 100)

- Base year is defined as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Greenhouse gases (GHG) calculated in accordance with the Calculation and Reporting Manual for Greenhouse Gas Emissions (Ministry of the Environment, Ministry of the Economy, Trade and Industry).

Note that GHG emissions associated with purchased power in FY2009 were calculated using the table of Emission Coefficients by Power Company (Ministry of the Environment).

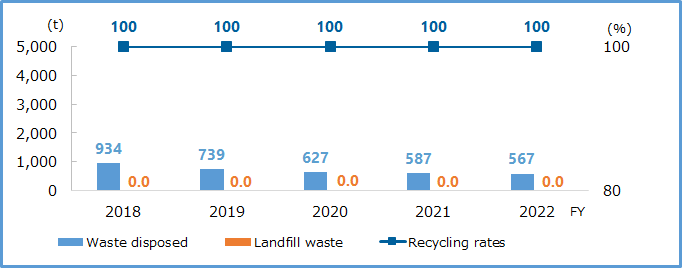

Effective use of resources / Waste reductions

Waste output

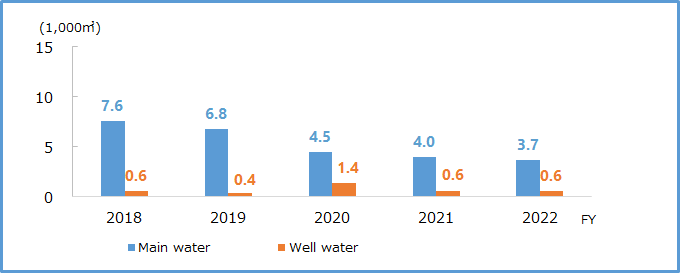

Water usage

Measures for discharges into water, air and soil

Data related to water contamination

Move the screen to the left or right to see the table information

| Plant Name Drain Name |

Item | Regulatory values | Voluntary standard values | FY2022 result | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Nagano Plant (Takamori) |

pH | 5.8~8.6 | 6.0~8.0 | 6.8 | 7.0 | 6.6 |

| BOD concentration (mg/l) | 160 | 22 or less | 2.1 | 2.3 | 1.9 | |

| COD concentration (mg/l) | 160 | 25 or less | 4.9 | 5.8 | 4.0 | |

| SS concentration (mg/l) | 200 | ― | 4.0 | 6.2 | 1.8 | |

| Plant and animal oil concentration (mg/l) | 5 | ― | 0.5 | 0.5 | 0.5 | |

| Mineral oil concentration (mg/l) | 5 | ― | 0.5 | 0.5 | 0.5 | |

| Nagano Plant (Toyooka) |

pH | 5.8~8.6 | 6.0~8.0 | 6.4 | 6.6 | 6.1 |

| BOD concentration (mg/l) | 160 | 22 or less | 4.2 | 5.7 | 2.6 | |

| COD concentration (mg/l) | 160 | 25 or less | 6.3 | 7.9 | 4.7 | |

| SS concentration (mg/l) | 200 | ― | 5.8 | 6.0 | 5.5 | |

| Plant and animal oil concentration (mg/l) | 5 | ― | 0.5 | 0.5 | 0.5 | |

| Mineral oil concentration (mg/l) | 5 | ― | 0.5 | 0.5 | 0.5 | |

- Not subject to legal regulation (Voluntary standard measurement, twice or more per year)

- Regulatory values are in compliance with the ordinances of Nagano Prefecture

- Takamori : Water discharged to Oshima River, Toyooka : Water discharged to Terasawa River

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

The Nagano Plant verifies whether secondary materials and auxiliary materials contain chemical substances subject to Safety Data Sheet (SDS) requirements, and in the case of substances where the amounts handled exceed the thresholds specified by the PRTR Law, annual reports are submitted to the national (or prefectural) authorities and safety impact assessment is performed.

Regarding the handling of substances pursuant to the PRTR Law, please refer to the Safety Evaluation Table of Domestic Production Bases.

Participation in the Tenryu River Environment Picnic (Cleanup)

The Tenryu River Environmental Picnic (garbage pickup), which we participate in every year, was postponed due to COVID-19.

Yokohama Forever Forest Tree planting Activity

With the completion of the planting of 6,905 trees, exceeding the cumulative total number in the plan, the activities were concluded in stage VI of 2013.

Although the provision of seedlings outside the company was continued after that, the continued provision became difficult after the move to Toyooka, and the activities were concluded with the donation of 1,040 seedlings to local municipalities and residents in December 2016.

Biodiversity conservation activities

As part of biodiversity conservation activities that were started from fiscal 2013, we have conducted monitoring surveys in the spring and fall of every year downstream in the Oshima River where rainwater is discharged from Takamori and near its junction with the Tenryu River, as well as downstream in the Terasawa River where rainwater is discharged from Takamori and along the agricultural-water runoff ditch located at Kono Hydrophilic Park.

Activities have been resumed since FY2021 by demarcating a regulating pond on the plant site.

Satoyama Conservation Activity

On June 10, 2022, after a three-year absence, eight people resumed satoyama conservation activities and worked on underbrush and undergrowth maintenance.

Underbrush and undergrowth maintenance work in satoyama conservation activities

Underbrush and undergrowth maintenance work in satoyama conservation activities

MD Squad activities

The MD team's activities included promotion of paperless office, 2S on OA servers, waste rag collection, stocking collection, 2S patrols, heat measures through green curtains, reduction of confidential document disposal costs by introducing shredders, reduction of purchase costs & waste by introducing rental items, review of outsourced cleaning details, review of purchased items, and energy saving activities. Reviewing the contents of outsourced cleaning, reviewing purchased goods, energy saving activities, etc.

In particular, for energy conservation, we have introduced equipment that can quantify the amount of compressed air leakage and have been working to improve air leaks from facilities.

In addition, we have achieved zero rag purchases through rag collection activities.

green curtain

green curtain

Waste rag collection

Reinforcing Month for rag cloth recovery

Fair Operating Practices

Thorough statutory compliance

In fiscal year 2022, there were no legal violations or external complaints.

Consumer Issues

Internship

Due to COVID-19, this program was not implemented in FY2022.

Community Involvement and Development

Donations to assist the local community

Due to COVID-19, the event was cancelled.

Donations were made to the Red Feather Community Chest.

Employee Communication

The labor-management sponsored event, which had been cancelled due to COVID-19, was implemented by inviting a kitchen car after considering infection control measures. 490 meals were served in December 2022.

Blood donations

June 15: 35 participants

November 15: 28 participants