Ibaraki Plant (IP)

Production of high-pressure hoses, sealing materials

Total site area152,000m2

Number of employees267 (as of the end of December 2022)

Location1 Hatori-Nishi, Omitama City, Ibaraki 319-0198, JAPAN

Contact for consultation and complaintsTadashi Kamimura, Plant Management Division

Tel: +81-299-46-1111

Fax: +81-299-46-0235

E-mail: tadashi.kamimura@y-yokohama.com

Message from the General Manager

Takashi Kojima

The Ibaraki Plant began operations in 1974, followed by the construction of a second plant in 2001 and a third plant in 2009, and has continued to this day as a plant for the production of high and low pressure hoses for hydraulic and automotive piping applications.

We are committed to becoming a top-level environmentally friendly company that embodies "Caring for the Future" for the sake of the global environment, based on our management policy of "valuing fairness to society and harmony with the environment".

In addition, we are promoting various activities to harmonize and integrate with the rich natural environment of Ibaraki, and to contribute to the local community and society in order to achieve this symbiosis, in addition to our environmental policy.

Furthermore, the planting of trees at the plant, which began in 2008, was completed in 2012, we continue to grow seedlings. We donate these saplings to both local and outside organizations for their tree-planting events.

As part of our biodiversity activities started in 2013, we have conducted bird watching, insect watching, and vegetation surveys inside the plant, as well as water quality and aquatic life surveys of the Sonobe River at the outlet of plant effluent three times a year to investigate the impact of the plant effluent on nature. Although we have recently suspended large-scale activities due to the impact of COVID-19, we have been publicizing these activities to the local community in order to improve communication.

Additionally, our biodiversity activities have been recognized, in that in 2019 we were certified and continue by ABINC as a Living Creature Coexistence Office®.

We further strengthen our environmental management systems at the Ibaraki Plant, and push forward with the total-employee participation model, both with regard to those activities that make an environmental contribution, and with regard to the prevention of environmental trouble.

Organizational Governance

Decision-making processes and structures

The following three items have been established with respect to the structuring of the plant’s safety culture:

- Greet your guests properly

- Keep your appearance neat and tidy

- Be sure to point and call properly

With respect to the plant’s safety, environment and quality policies, such are established in accordance with corporate policy. Concerning their orientation, such is decided through the meetings system.

Human Rights

Consideration of human rights by suppliers

The April 2022 study session was held on the web due to the COVID-19 disaster.

The content of this meeting was the following 6 topics.

- ESG Management

- CSR Report and CSR Guidelines

- Workplace Safety

- Business Consultation Service

- Mid-term Environmental Plan and Initiatives

- Companies and Human Rights

Complaint resolution

There were no reports submitted to the Corporate Compliance Department in 2021, and no consultations requested.

Labor Practices

Creating a safe and healthy workplace environment

Based on the recognition that the basis of corporate activity is assuring the safety and health of both our employees and those of cooperating companies, Occupational Safety and Health Management System (OSHMS) certification in accordance with Japan Industrial Safety & Health Association (JISHA) standards was obtained, and safety and health management has been implemented. This was done as a means by which to realize a safe, comfortable, and healthy workplace.

As a future company-wide plan, we are considering a mid-term transition to ISO 45001 (Occupational Health and Safety Management System), and this plant will be preparing for the switchover in October 2025.

In addition, each section is conducting risk assessment and risk reduction activities for existing facilities. 12 risk level IV and V cases were addressed in FY2022, and 118 risk level III cases were addressed in FY2023.

Circle activities

We reduce all kinds of losses such as reduction of equipment breakdowns, quality defects, and improvement of workability. And, circle TPM improvement activities are being conducted to allow employees to make their own workplaces more comfortable and easier to work at. We are working to vitalize these activities through the holding of events including regular announcements on the results of improvements and bulletin board contests.

Human resources development and training

Work training is undertaken by our assignment of more senior workers to instruct both new hires and fixed-term employees. This one-on-one training increases individual skill levels because training results can be reviewed and revisited.

In addition, veteran employees systematically provide guidance on employee skills to ensure that product manufacturing skills are passed down from generation to generation.

Promotion of employment of people with disabilities

As part of our promotion of the employment of disabled people, we currently have one disabled employees working actively in the plant.

We will continue to implement improvements to create a barrier-free workplace, so as to foster the employment of disabled people.

Work-life balance

Two days a week, Wednesdays and Fridays, have been established as days with specified hours for leaving work.

The Environment

Environmental data

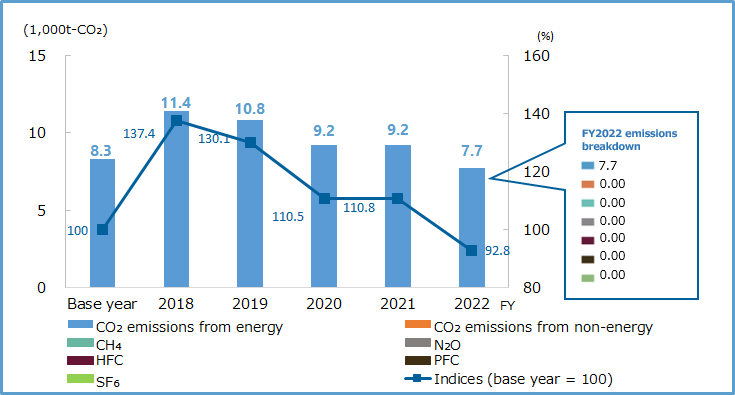

Reductions in greenhouse gas emissions

Greenhouse gas emissions

Greenhouse gas emissions have been gradually decreasing since fiscal 2010.

- The base year is defined as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Method of calculation of greenhouse gases (GHG): this is in compliance with the “Calculation and Reporting Manual for Greenhouse Gas Emissions” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Note that GHG emissions associated with purchased power in FY2009 were calculated using the Table of Emission Coefficients by Power Company (Ministry of the Environment).

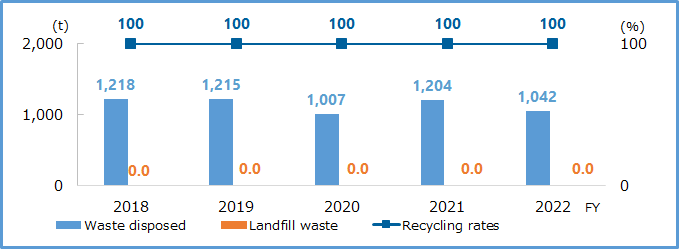

Effective use of resources / Reduction of waste

Waste output

From fiscal 2006, we have continued complete zero emissions.

Waste landfill

In fiscal 2007, we achieved a recycling rate of 100% and we have maintained that rate since.

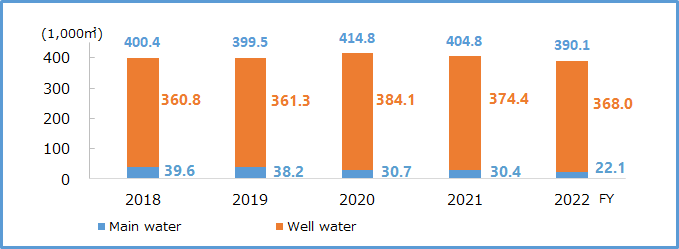

Water usage

The plant uses 400,000 tons of water a year.

Sources consist of underground water of about 90% and city waterworks of 10%.

Measures for discharge into water, air and soil

Data related to water contamination

The plant discharges about 430,000 tons of wastewater a year into the Sonobe River.

Move the screen to the left or right to see the table information

| Item | Regulatory values | Voluntary standard values | FY2022 result | ||

|---|---|---|---|---|---|

| Average | Maximum | Minimum | |||

| pH | 5.8~8.6 | 6.7~8.2 | 7.6 | 8.1 | 7.2 |

| BOD concentration (mg/l) | 10 | 6.5 | 2.4 | 5.3 | 1 |

| COD concentration (mg/l) | 10 | 5.5 | 1.7 | 2.8 | 1 |

| SS concentration (mg/l) | 15 | 5 | 1 | 1 | 1 |

| Mineral oil concentration (mg/l) | 3 | 0.8 | 0.5 | 0.5 | 0.5 |

- Ibaraki Prefectural Ordinance and Environmental Protection Agreement with Omitama City

- Discharge point: Sonobe River

Soil contamination

We conduct groundwater analysis (shallow well) once a year and confirmed that the standard values were within the laws and the ordinances of Omitama City.

Air pollutants (NOx, SOx)

Measurements are conducted twice a year, and we have confirmed that the results are within the standards set out in all laws and in Omitama City Ordinances.

Move the screen to the left or right to see the table information

| Substance | NOx | SOx |

|---|---|---|

| Amount of emission (t/year) | 1 | 0.3 |

| Facility | Item | Regulatory values | Voluntary standard values | FY2021 result | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Ibaraki Plant No.1-No.3 Boiler |

SOx emissions (K-value) NOx (ppm) Soot and dusts (g/m3N) |

17.5 260 0.3 |

10 or less 125 0.1 |

0.32 45 0.004 |

0.54 59 0.006 |

0.16 12 0.003 |

- The Air Pollution Control Act and Environmental Protection Agreement with Omitama City.

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

The Ibaraki Plant verifies whether secondary materials and auxiliary materials contain chemical substances subject to Safety Data Sheet (SDS) requirements, and in the case of substances where the amounts handled exceed the thresholds specified by the PRTR Law, annual reports are submitted to the national (or prefectural) authorities and safety impact assessment is performed.

Regarding the handling of substances pursuant to the PRTR Law, please refer to the Safety Evaluation Table of Domestic Production Bases.

Noise reduction

Noises are measured at 15 places on the border of the plant premises once a month. We can confirm that the results are within the standards set out in Omitama City Ordinances (below 55db).

Preventing pollution

So as to prevent risks to the environment, once a year we conduct drills and tests in response to predicted emergency scenarios (such scenarios include oil leaks occurring from heavy oil storage tanks and solvent cans being upset during transportation, etc.).

Industrial Waste Reduction Initiatives

To reduce industrial waste, we promote activities to reduce product and semi-finished product scraps and waste separation mainly by each process manager. We are working to reduce the amount of waste by recycling waste plastics used in manufacturing processes.

Alleviating and responding to climate change

As energy saving activities, we are promoting the use of LED lighting, improvement of air conditioning efficiency by adopting MiRACLE coils, and horizontal deployment of heat insulation and heat retention.

We also conduct energy conservation patrols every month and continue to make repairs mainly to air, steam, and water leakage points.

During Energy Saving Month activities, all employees participated in energy saving promotion activities, making suggestions and improvements related to energy waste.

Environmental protection, and recovery of natural habitats

Concerning the Sonobe River into which discharges from this plant flow, biodiversity protection surveys have been conducted at a frequency of two times a year. During these surveys, we have monitored water quality, aquatic life, plants and birdlife, etc. We have also taken steps to eliminate certain species of introduced plant and aquatic life.

In addition, starting in 2019, we have organized a new "Survey on the Living Environment of the Grey-faced buzzard (Butastur indicus) " to survey the vegetation and small animals (amphibians and reptiles) in the plant, focusing on the Grey-faced buzzard, which is as a Vulnerable, as one of the indicators for environmental conservation.

With the cooperation of the Omitama Wildlife Society and the Wild Bird Society of Japan, Ibaraki Prefecture, we will continue to exterminate and monitor invasive alien species three times/year.

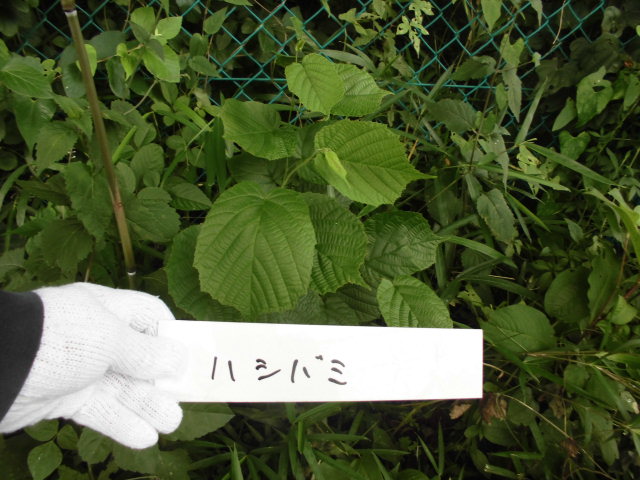

Vegetation Survey

Vegetation Survey

Water quality survey

Aquatic organism survey

Bird survey

Endangered species II " Asian Hazel " found in the plant

The " Gray-faced Buzzard-Eagle " confirmed during biodiversity preservation activities

Fair Operating Practices

Thorough statutory compliance

The managers mainly responsible for placing orders with subcontractors have participated in seminars dealing with the improvement of subcontracting transactions. In addition, all personnel acting as subcontractor contact persons attended the subcontractor study sessions organized by the Indirect Materials Procurement Department that were held at the plant, reinforcing their understanding of legal requirements.

Consideration of supplier labor, safety and workplaces

Business dealings are conducted that are fair, transparent, openly competitive and suitable.

Thorough compliance

At the 10th CSR Study Meeting, the following information was shared.

- Yokohama Rubber's CSR Activity Policy

- Workplace Safety

- Corporate and Human Rights

- Supplier Consultation Desk

As education within the company, we hold compliance seminars at a frequency of once a month.

Consumer Issues

Responses to complaints

If any complaints are raised about products, we quickly collect the actual item and investigate the causes and prepare reports to make a response satisfactory to the customer.

Community Involvement and Development

Coexistence and shared prosperity with the local community

We had planned to hold a round-table discussion on biodiversity conservation activities, but due to the outbreak of COVID-19, we decided to postpone the meeting in the plant and distribute related materials.

Employment creation

In FY2022, we hired six new employees and six mid-career hires from high schools near the plant.

Regional contributions

Due to the COVID-19 infectious disease outbreak, events such as the Hatori Fureai Plaza and the Omitama City Fureai Festival were cancelled in FY2022 as well.

At the Green Festival 2022 held on November 23 in Naka City, Ibaraki Prefecture, 100 saplings were provided free of charge as gifts for visitors at the booth of the Ibaraki Prefecture Forestry and Forestry Association.

The Otsuchi Gakuen "Furusato Department" tree-planting event, in which we are participating as volunteers, was held on April 28 while taking measures against COVID-19 infection, and 62 saplings were provided free of charge.

The provided saplings were planted in the Shonan International Village Meguri no Mori project and distributed as gifts to participants.

Seedlings donated to Silva, a non-profit general incorporated association

Discussion for local residents regarding our activities to help safeguard biodiversity

Although we had planned to hold a meeting with local residents to discuss biodiversity conservation activities, we decided to hold the meeting in writing, considering the safety of local residents as our first priority.

Relationship with local societies

As part of our efforts to foster close communication with local government authorities and local corporations, we attend the regular meetings of the local corporation association to exchange views and share information with the Mayor, local councilors and the managers of other local corporations. (The annual meeting hosted by the Minosato Area Business Liaison Association, February: 13 companies participated in writing) hosted by the Minosato Area Business Liaison Association, February: 13 companies participated in writing)

Plant tours

We only conducted a tour for job seekers (high school students) in July 2022.

While looking at the situation of COVID-19, we are being promoted to communicate with neighboring areas.