Onomichi Plant (OP)

Production of tires for large construction vehicles, mining vehicles and industrial vehicles.

Total site area193,000m2

Number of employees425 (as of December 2022)

Location20 Higashi-Onomichi, Onomichi City, Hiroshima 722-0051, JAPAN

Contact for consultation and complaintsPlant Control Section

Tel: +81-848-46-4580

Fax: +81-848-46-4579

Message from the General Manager

Tetsuro Murakami

The Onomichi Plant is situated overlooking the islands of the Setouchi Shimanami Sea Route and is Yokohama Rubber's main production plant for tires for large construction/mining and industrial vehicles.

We conduct our activities with the aim of “becoming a company with world class technologies for protecting the environment,” as stated in Yokohama Rubber Environmental Policy, and based on “bright, happy and vigorous” activities and cherishing greetings and the “5S” activities. With regard to environmental matters, we have carried out the improvement of equipment, the reviewing of mechanisms, and repeated educational activities for the purpose of preventing a recurrence of any past environmental trouble. Such has also been carried out in order to realize a reduction of environmental risk, a reduction of greenhouse gas emissions and a reduction of industrial waste.

Meanwhile, in terms of contribution to the local community and communication activities, we have been taking into consideration the status of COVID-19, opening the "Dinosaur Park" on the plant premises to the public, accepting children, students, and guests for plant tours, participating in local cultural activities and events, and promoting the "Heisei no Mori" project in Otsuchi Town, Iwate Prefecture. We continue to actively participate in local cultural activities and events, and promote the creation of a " Forever Forest" in the town of Otsuchi, Iwate Prefecture. Furthermore, we commenced a biodiversity protection survey in 2013, and we have been continued our measures to maintain and improve biodiversity, both here on the plant premises and in the neighboring watercourses.

In terms of biodiversity conservation surveys, we have been continuing our efforts since 2013 to maintain and improve the biodiversity of the plant grounds and neighboring water bodies.

Yokohama Rubber's Onomichi Plant will continue to contribute to society in consideration of the global environment, and will conduct its business activities with the aim of becoming a business site that is trusted and loved by everyone.

Organizational Governance

Under the factory policy to promote safety, environment, and quality improvement, we make employees aware of the policy through regular morning meetings, and promote PDCA (Plan-Do-Check-Act) of specific improvement measures at annual, quarterly, and monthly meetings. In our day-to-day operations, by carrying out our work according to carefully documented standard operating procedures, we are able to implement a management system that prevents improper working methods, and we also undertake ongoing improvement.

In addition, compliance education is provided to managers and staff every month to raise awareness of the importance of compliance among all employees.

Morning meeting

Morning meeting

TPM instruction

Human Rights

Respect for human rights

In order to create a pleasant workplace where employees can work cheerfully, happily and energetically, we conduct workplace education, covering a variety of areas including information management, workplace bullying and harassment prevention, etc., every month. The content of this training involves the management of information and other issues such as workplace bullying, etc. We also maintain close collaboration with the Corporate Compliance Department regarding compliance-related reports and consultations, and if a problem occurs, we will promptly respond to it.

Labor Practices

Occupational safety and health measures

The plant obtained Occupational Safety and Health Management System (OSHMS) certification and has continued its certification activities. In FY2022, there were 0 lost time injuries, 1 lost time injury, and 10 minor injuries. Many accidents (75%) were caused by careless and unreasonable movements and falls, and we took steps to prevent recurrence by reviewing work procedures, deploying them in other sections, and conducting safety patrols. Moreover, by focused safety education activities, the revision of standard operating procedure (SOP) manuals through open work observations, individual education based on safe employee evaluation, the undertaking of one-on-one training between deputy work supervisors and workers, mutual advice, and daily “KYT” Hazard Prediction Training activities, we are working to heighten the consciousness of our employees with respect to safety.

In addition, we are continuing to take measures to reduce the risk of high-risk areas caused by equipment through comprehensive safety inspections.

Based on the recognition that the safety and health of all workers is the foundation of corporate activities, we will work to prevent occupational accidents and create healthy and comfortable workplaces.

Action Guidelines- We will educate all plant workers on the importance of safety and health, provide the necessary education and training, instill a safety-first mindset, and build a culture of safety to develop human resources capable of taking action to ensure safety.

- Reduce risks by prioritizing and systematically improving issues extracted from risk assessments and daily near-misses in terms of laws, regulations, safety, disaster prevention, and the workplace environment by breaking them down into personnel, equipment, and operations.

- We will improve the work environment in the workplace through education and activities so that 5S activities (Seiri, Seiton, Seiso, Seiketsu, and Shitsuke) can be practiced voluntarily.

- We will promote the creation of a comfortable work environment through the improvement of the work environment and mutual communication, and work to improve the mental and physical health of our employees.

- As a business involved in the automotive industry, we proactively engage in activities that contribute to the prevention of traffic accidents thus aim to achieve the distinction of recording zero harmful accidents.

Jan-2023

Tetsuro Murakami

General Manager, Onomichi Plant

Education and training for employees.

- We conduct monthly open work observation using standard work manuals and abnormal work procedures to identify potential hazards in the work and review the standard work manuals and abnormal work procedures afterwards.

- Furthermore, when the standard work manuals and abnormal work procedures are reviewed, one-on-one training is conducted between the supervisor and the worker to confirm the level of understanding of the training content.

- We provide training at the "sensory training center" for employees to actually experience the hazards of work. Once a year, the Safety and Health Section staff conducts a hands-on training for employees who have been with the company for less than three years.

- Three members of the Safety and Health Section have recently acquired certification as first-aid instructors and are now able to conduct training at their own plants.

Although the COVID-19-related training has been slow, we plan to increase the number of certified lifesaving instructors by actively holding more lifesaving courses in the future.

Responses in case of disaster

- We conduct a comprehensive evacuation drill once a year to ensure that we can respond quickly in the event of a natural disaster. In addition, since natural disasters can occur in the middle of the night, nighttime evacuation drills are also conducted for all employees.

- All employees are given instructions on how to use a fire extinguisher in the event of a fire or other emergency situation. Drills are also conducted using water fire extinguishers (for training purposes).

Promotion of employment of people with disabilities

Three disabled employees are performing clerical and light-duty duties at the plant, and will continue to work toward hiring new employees in FY2023.

Work-life balance

In aiming to improve the work-life balance of our employees, we manage overtime and promote the use of at least five paid holidays per year.

The Environment

Yokohama Rubber operates an environmental management system that is completely integrated throughout the entire company and makes efforts toward reducing risks by risk identification, countermeasures and improvements in areas exposed to environmental risks, through environmental risk management, implements its operations in compliance with relevant laws and ordinances, including the Pollution Control Agreement between the Onomichi Plant, Hiroshima Prefecture and Onomichi City, and looks to reduce risks by spreading awareness of nonconformities and small incidents at other Yokohama Rubber facilities. We are also implementing improvements to achieve ongoing enhancement of environmental performance, including a reduction of industrial waste and reduction of GHG emissions by promotion of energy savings. As a result of a plan to increase our internal audit staff according to corporate policy so as to further strengthen the ISO 14001 management system, we currently have 81 internal audit staff registered. We will further increase the number of staff according to our plan.

As one of our environmental activities, we have participated in the "Green Curtain Contest" sponsored by Onomichi City, and have won consecutive awards and been inducted into the Hall of Fame.

In line with Yokohama Rubber’s management policy “Deal fairly with society and value harmony with the environment,” we strive to embody genuine consideration for the global environment, and to be a top-level business in terms of our contribution to the environment.

- The Onomichi Plant addresses measures in consideration of the environment in all of its activities under the leadership of top management, and it implements world-class environmental activities.

- The Onomichi Plant continues its education and enlightenment programs so that each one of its employees understands this Policy and acts accordingly.

- The Onomichi Plant has strengthened its Environmental Management System in order to become a plant trusted by local communities and it continues to advance management with a proactive stance in order to prevent environmental pollution and improve the environment, while aiming to reduce environmental risk to zero.

- The Onomichi Plant complies with related laws, regulations and agreements, etc. It promotes harmony with local communities, and works to make both a regional and social contribution.

- To achieve carbon neutrality, the Onomichi Plant will promote energy-saving activities. We will promote less use and reuse of resources to realize a recycling-oriented society.

- We will maintain the lush green Forests of Forever Forest on the site and contribute to the preservation of the biodiversity of the Seto Inland Sea.

- In order to realize the Environmental Policy, the Onomichi Plant shall implement effective environmental management coordinated with its efforts to safeguard the local environment.

- This Policy shall be published.

1-January 2023

Tetsuro Murakami

General Manager, Onomichi Plant

Environmental data

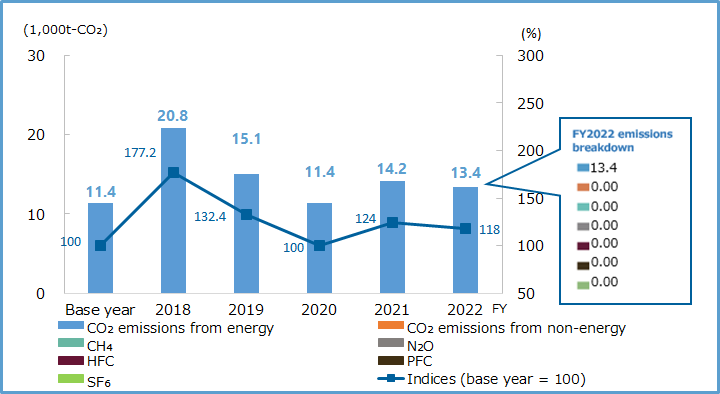

Reductions in greenhouse gas emissions

The plant’s major energy sources are electricity and the city gas which is used as boiler fuel. Of the energy used in fiscal 2022, electricity accounted for 54.0%, city gas for 45.4% and other fuel sources 0.6%.

Greenhouse gas emissions

In order to reduce environmental loads, we have made efforts toward reducing GHG emissions by reduction targets for GHG emissions (total amount). In fiscal 2022, our energy-saving activities progressed as planned.

- The base year is defined as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Method of calculation of greenhouse gases (GHG): this is in compliance with the “Calculation and Reporting Manual for Greenhouse Gas Emissions” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Note that GHG emissions associated with purchased power in FY2009 were calculated using the Table of Emission Coefficients by Power Company (Ministry of the Environment).

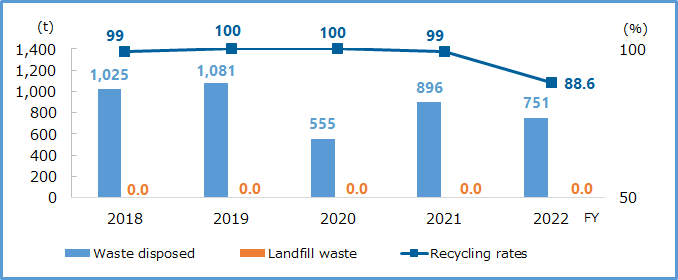

Effective use of resources / Reduction of waste

Waste output

landfill disposal, resulting in a recycling rate of 88.6%.

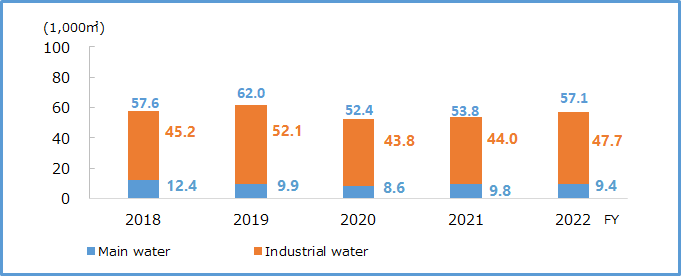

Water usage

The Onomichi Plant collects industrial water from the Numata River water system (river water) that flows in Hiroshima Prefecture.

Water is collected from the city waterworks of Onomichi City. We are working to reduce the amount of water use by circulating plant cooling water. Furthermore, we have implemented improvement measures by setting reduction targets.

Measures for discharge into water, air and soil

Data related to water contamination

Our plant mainly uses water from the Numata River water system in Hiroshima Prefecture.

We discharge rain water into a public body of water and life system water is discharged into the sewage system of Onomichi City. The water quality of discharges is managed by setting voluntary standard values.

Move the screen to the left or right to see the table information

| Item | Regulatory values | Voluntary standard values | FY2022 result | ||

|---|---|---|---|---|---|

| Average | Maximum | Minimum | |||

| pH | More than 5–less than 9 | 5.4 or more–8.6 or less | 7.4 | 7.8 | 7 |

| BOD concentration (mg/l) | Less than 600 | Less than 315 | 11.2 | 21 | 5.7 |

| SS concentration (mg/l) | Less than 600 | Less than 200 | 5.6 | 10 | 2 |

| Plant and animal oil concentration (mg/l) | 5 or less | Less than 2.0 | 1 | 1 | 1 |

| Mineral oil concentration (mg/l) | 30 or less | Less than 24.0 | 1.1 | 2 | 1 |

- Regulatory values are in compliance with the Onomichi City Sewage System Ordinance. Voluntary standard values were changed in September 2012.

Air pollutants (NOx, SOx, soot and dust)

Sooty smoke is measured twice a year by each individual boiler in order to monitor emissions and the density of pollutants. As a result of switching the fuel of boilers to city gas, emissions of Sulfur oxides into the air are now minimal. Thus, the Pollution Control Agreement was amended in March 2013. As a result of this development, the measurement of SOx is no longer necessary.

Move the screen to the left or right to see the table information

| Item | NOx | SOx |

|---|---|---|

| Amount of emission (t/year) | 3 | ― |

| Facility | Substance | Regulatory values | Voluntary standard values | FY2022 result | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Onomichi Plant Boiler 1 | NOx (ppm) Soot and dust (g/m3N) |

150 0.10 |

123 or less 0.011 or less |

65 Less than 0.015 |

72 Less than 0.002 |

58 Less than 0.001 |

| Onomichi Plant Boiler 2 | NOx (ppm) Soot and dust (g/m3N) |

150 0.10 |

120 or less 0.05 or less |

91 Less than 0.001 |

100 Less than 0.001 |

81 Less than 0.001 |

- In compliance with the Pollution Control Agreement with Hiroshima Prefecture and the Pollution Control Agreement with Onomichi City.

Soil contamination

In order to monitor the status of contamination of soil by specified hazardous substances, we voluntarily measure and monitor the constituents of groundwater once every few years.

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

The Onomichi Plant verifies whether secondary materials and auxiliary materials contain chemical substances subject to Safety Data Sheet (SDS) requirements, and in the case of substances where the amounts handled exceed the thresholds specified by the PRTR Law, annual reports are submitted to the national (or prefectural) authorities and safety impact assessment is performed.

Regarding the handling of substances pursuant to the PRTR Law, please refer to the Safety Evaluation Table of Domestic Production Bases.

Biodiversity conservation activities

As biodiversity conservation activities, we had planned to conduct conservation of the Fujii River near the plant, which flows into the Seto Inland Sea, as well as monitoring surveys of birds on the plant grounds and conservation activities three times a year.

In FY2022, activities in February were cancelled in order to comply with COVID-19, and were conducted twice in May and October.

Monitoring activities within the grounds of the plant

Monitoring activities at the Fujii River Water Park

Bird observation on the plant premises (white-winged teal)

Fair Operating Practices

Communication with business partners

In collaboration with the Materials Procurement Department and Raw Materials Procurement Department, we collect opinions and requests from business partners and then respond to them sincerely. We also respond appropriately to questionnaires received from business partners.

Furthermore, we are constantly hosting plant tours both by manufacturers who purchase our products and sales agents. These tours give the visitors an opportunity to inspect the production frontlines and to confirm the quality of our products.

Consumer Issues

Responses to complaints

When defect information is received from the market, we analyze the usage conditions and the failed tire to determine the cause. The results of the analysis are reported to the customer via the department in charge. 74 analysis reports were submitted in fiscal year 2022. The majority of the failures were caused by usage conditions, but in cases where the failure was due to manufacturing or design factors, we promptly implement countermeasures to prevent recurrence.

Community Involvement and Development

Relationship with local societies

As a place of recreation for people in the region, we open the Dinosaur Park to the public every day, from 8:00 a.m. to 4:30 p.m. In order to make the house more comfortable, the area around the cherry tree roots has been cleared.

In fiscal 2022, a total of 2,780 persons visited the Dinosaur Park.

We received one group for a plant tour.

The Dinosaur Park is open to the public

The Dinosaur Park is open to the public

Participation in local activities

In FY2022, most events were cancelled due to the COVID-19 disaster.

Sponsorship of Onomichi Truck Festival (September) was cancelled.

Onomichi Lantern Festival (October) 8 volunteers participated in preparation and clean-up

Blood donation activities by employees (Cancelled due to COVID-19)

Beautification activities around the plant (once a month) (95 participants)

Fujii River Evening Festival (June 2022) was cancelled

Fujii River Evening (June 3, 2023)

Fujii River Evening (June 3, 2023)

Plant tour and workshop

We accept requests for plant tours from schools and companies from time to time.

Available days: Days when plant is in operation: from Monday to Friday

(Except for year end and New Year holidays, and consecutive holidays in May and August)

Hours: 9:00 a.m. to 3:00 p.m.

Contact: Onomichi Plant, Plant Control Section

Tel: +81-848-46-4580

A 30-minute walk from Higashi-Onomichi Station.