Mishima Plant (SP)

Production of tires for passenger cars

Total site area112,000 m2

Number of employees1,012 (December 2022)

Location8-1 Minami-Futsuka-machi, Mishima City, Shizuoka 411-0832, JAPAN

Contact for consultation and complaintsMishima Plant Operation Division

Tel: +81-55-975-0800

Fax: +81-55-976-4322

Message from the General Manager

Toshinari Matsumoto

The Mishima Plant is located in Mishima City in the North Izu area of Izu Peninsula UNESCO Global Geopark in eastern Shizuoka Prefecture. Mt. Fuji, a World Heritage site, can be seen to the north from the plant, and the area is blessed with magnificent scenery and bountiful blessings.The plant mainly manufactures tires for passenger cars and light trucks. We are also the only company in the Yokohama Rubber Group that manufactures racing tires for motorsports.

The plant is surrounded by clear water that is part of the natural abundance of Mt. Fuji and the Izu Geopark, and thanks to the tree planting of the Yokohama Forever Forest Project that the Yokohama Group has been engaged in since 2007, it has been possible to see fireflies in the early summer in the tree planting areas in front of the plant in recent years. Meanwhile, residential areas have been developed in the area surrounding the plant as a result of the convenience of the proximity to the Mishima-Futsukamachi Station on the Izuhakone Railway, which means that in addition to control and management of exhaust, drainage, and sound, response to sensory issues such as odors is required, and these are being steadily addressed.

While Yokohama Rubber is aiming to contribute as a member of the global community, the plant is aiming to contribute as a member of the local community.

We would like to foster the abundant natural wealth of the region through participation in clean-up activities around the plant and the Rakujuen section of the Izu Geopark that are currently underway as well as environmental conservation and observation through environmental conservation near the IzuJukan Expressway/Tamazawa IC and biodiversity activities at the Goten River that flows along the west side of the plant.

In FY2022, we are continuing the infection prevention measures of COVID-19, avoiding the 3 secret measures and thoroughly enforcing the basics of gargling, washing hands and wearing masks.

In the future as well, we will work hard to build trusting relationships with all stakeholders in an aim to be a plant that is loved by the region.

Organizational Governance

Corporate Governance and Compliance

The Mishima Plant has also developed its activities in line with Yokohama Rubber's important task of becoming "a company that contributes to the earth, earning the unwavering trust of society. In addition, as a priority issue of reducing environmental risks and contributing to the local community while strengthening the environmental management system, we are deepening communication with stakeholders, preventing environmental pollution and sensory pollution, regularly reviewing past environmental troubles and near misses, and continuously promoting environmental improvement through proactive management.

Corruption prevention

In working to give employees a thorough understanding of our compliance policies as such relate to the prevention of quality fraud, education in compliance issues has been conducted for the entire workforce.

Human Rights

Education on respect for human rights

We distributed “compliance cards” to all employees so as to enlighten and educate them about human rights.

In addition, we conducted compliance education related to human rights to ensure understanding and thoroughness.

We offer employment irrespective of gender, age or disability.

Promotion of employment of people with disabilities and workforce diversity

Currently, we have 12 employees with disabilities.

As of December 2022, of a total of 685 employees at the plant, 35 are women, and 39 are elderly individuals (persons aged 60 or over).

Labor Practices

Occupational safety and health

Recognizing that securing the safety and health of our employees and employees of partner companies are the foundations of corporate activities, the plant acquired OSHMS (Occupational Safety and Health Management System) certification in November 2010 as a means to realize a safe, healthy and comfortable workplace. We promote safety and health activities by identifying risks through risk assessment activities and reducing risks through countermeasures and improvements, based on 3S activities and KY before work with the participation of all employees.

Employee diversity

In 2022, Zero employees took nursing care leave and 25 employees took parental leave.

Work-life balance

The second and fourth Fridays of even month are designated as “Happy Family Life Days,” and employees are encouraged not to work overtime on these days.

Human resources cultivation and training in the workplace

To enhance the knowledge and skills required of employees, we implement level-based training that is conducted according to years of experience and position. We have made a plan to provide the right training at the right time. In 2022, despite the impact of COVID-19 infection spread prevention measures, we continued to implement thorough infection prevention measures and conducted group training for 47 employees and Mishima Plant's own role-based training for 12 employees, for a total of 59 employees.

The Environment

Environmental management

Following the principle of dealing fairly with society and valuing harmony with the environment, we shall embody “Caring for the Future” for the global environment and assert our world-class strengths in technologies to protect it.

- Under leadership of top management, Mishima Plant will globally initiate environmentally-conscious measures in all of its activities, and will put this into practice across its entire organization

- Mishima Plant will deepen communication with its stakeholders and will strive to make contributions to local communities and to society as a whole by promoting collaboration to working with the value chain.

- Mishima Plant will strengthen its environmental management system and will aim to achieve zero environmental risk by continually striving to help improve the environment by using approaches to mitigate its impact with chemical substance management, prevent environmental pollution, and reduce sensory nuisances.

- Mishima Plant will comply with all related laws, regulations, and agreements as well as endeavor to continually implement activities that help improve the environment.

- Mishima Plant will promote decarbonization measures, such as energysaving activities and the introduction of renewable energy, and strive to conserve and recycle resources in order to realize a carbon-neutral and circular economy.

- Mishima Plant will strive to conserve biological diversity and use biological resources sustainably in its business activities.

- Mishima Plant will promote harmony with local communities as part of its commitment to work with and become a company that is trusted by local communities.

- Mishima Plantl provide education and awareness to all people working at the factory so that they understand and act on this policy.

- Mishima Plant shall publish this policy.

July 1, 2023

Toshinari Matsumoto,

General Manager,

Mishima Plant, Yokohama Rubber Co., Ltd.

In line with our principle of “Deal fairly with society and value harmony with the environment”, we declared an environmental policy, adopting the environmental management system of ISO 14001. In order to reduce the environmental burden, we established reducing industrial waste and reducing greenhouse gas emissions as major tasks and actively strive to improve our production process and eliminate energy waste. As regards other measures, we established autonomous management targets to respond to legal regulations and operate within the autonomous management targets.

In response to sensory pollution such as noise, odor, and vibration, three deodorizers are in operation and spraying 24 hours a day during operation as odor countermeasures. We have received cooperation from 28 residents (as of December 2022) living in the four towns surrounding the plant as environmental monitors, and have visited them once a month to report on the situation at their homes and conduct interviews, leading to improvements.

However, in order to prevent the spread of COVID-19, we refrained from visiting them in person. Instead, we refrained from visiting them directly. Instead, we distributed direct mail and CSR reports, and responded to inquiries by phone.

As part of our efforts to contribute to the regional environment, we have planted 29,646 trees (as of December 2022) in the YOKOHAMA Forever Forest Project, which is also a company-wide activity, as well as in a tree-planting event at Otsuchi Gakuen in Otsuchi Town, Iwate Prefecture.

In Shizuoka Prefecture, we have been supporting Kakegawa City's “ Creating a Forest of Hope'' seawall, but in 2022, this event was held only by companies in Kakegawa City.

Tree planting event with Otsuchi Gakuen, Otsuchi Town, Iwate Prefecture

Tree planting event with Otsuchi Gakuen, Otsuchi Town, Iwate Prefecture

Kakegawa City seawall “Creating a Forest of Hope” (2019)

Kakegawa City seawall “Creating a Forest of Hope” (2019)

Concerning the protection of biodiversity, we have conducted team surveys of the upper, middle and lower reaches of the Goten River (in our neighborhood). Those activities have involved measurements of water quality, ecological observations being undertaken.

We have observed a wide variety of living creatures live in the river, including dragonfly nymphs (e.g. Calopteryx atrata, Macromia amphigena), fish (e.g. Opsariichthys platypus and Nipponocypris temminckii), reptiles such as Soft-shelled turtle and Chinese pond turtle and the symbol birds of Mishima City, such as Kingfishers, which are rare in a factory surrounded by houses.On the other hand, there is a lot of garbage dumped in the river, and we have been cleaning the river after monitoring in order to contribute in some small way to keep the Goten River beautiful.

However, river vegetation was wiped out by river dredging at the end of 2016, and the diversity of the river disappeared.

Therefore, in May 2019, the Numazu Civil Engineering Office of Shizuoka Prefecture, Mishima City, and the Mishima Plant signed a River Friendship agreement, and in 2020, we conducted activities with government participation twice a year to regenerate vegetation and create a comfortable environment for aquatic life in the Goten River.

In addition, as a result of cleaning up the agricultural waterway in front of the main gate of the plant, fireflies began to inhabit the river in 2012, and a firefly viewing party was held every year in May.

In 2019, we welcomed 281 visitors, but due to measures to prevent the spread of COVID-19 infection, we have decided to cancel the event in 2022. In the future, we intend to build on such biodiversity protection activities.

catfish (esp. the Amur catfish, Silurus auratus)

Soft-shelled turtle and Red-eared slider (at the outlet of the final factory drain)

We planned to hold four activities in 2022, but all of them were canceled due to bad weather and Typhoon No. 15.

River Friendship collaborative activities

Environmental data

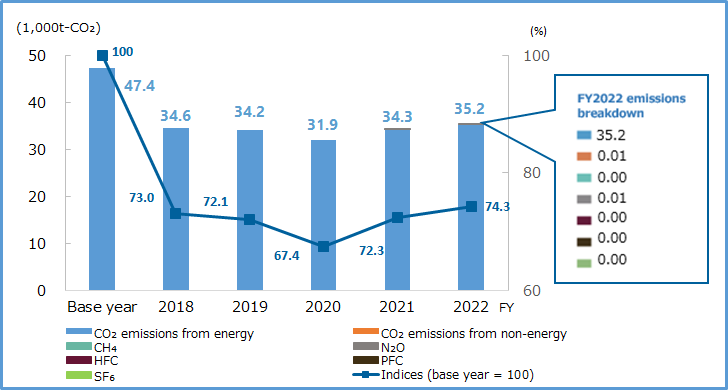

Reductions in greenhouse gas emissions

Greenhouse gas emissions

- The base year is deemed as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Method of calculation of greenhouse gases (GHG): this is in compliance with the “Calculation and Reporting Manual for Greenhouse Gas Emissions” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Note that GHG emissions associated with purchased electric power in FY2009 were calculated using the Table of Emission Coefficients by Power Company (Ministry of the Environment).

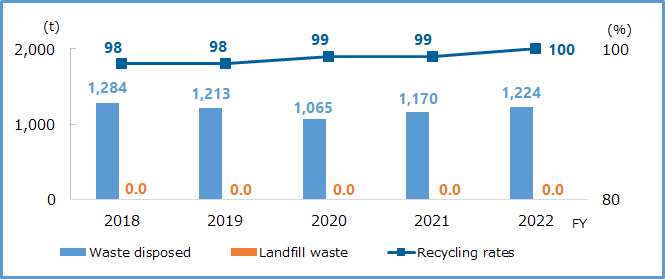

Effective use of resources / Reduction of waste

Waste output

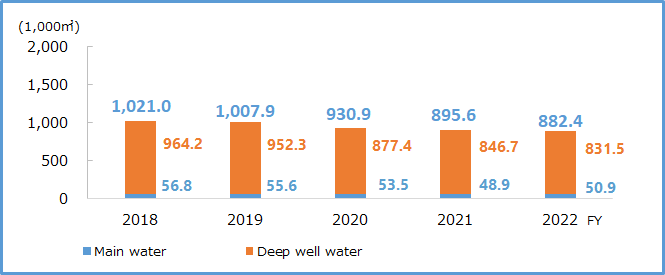

Water usage

The plant derives 90% of its total water usage from underground water. The remainder is from city waterworks.

Measures for discharge into water, air and soil

Data related to water contamination

The water used at the plant is discharged into the Goten River after being treated in the plant’s treatment facilities.

Move the screen to the left or right to see the table information

| Item | Regulatory values | Voluntary standard values | FY2022 results | ||

|---|---|---|---|---|---|

| Average | Maximum | Minimum | |||

| pH | ※5.8~8.6 | 6.2~8.2 | 7.6 | 7.8 | 7.4 |

| BOD concentration (mg/l) | 15 | 4 or less | 1.4 | 2.7 | 0.6 |

| COD concentration (mg/l) | ★120 | 5 or less | 2.3 | 5.4 | 1.3 |

| SS concentration (mg/l) | 20 | 8 or less | 1.0 | 1.0 | 1.0 |

| Oil concentration (mg/l) | 2 | 1 or less | 1.0 | 1.0 | 1.0 |

- Agreement on Environmental Protection with Mishima City; Star marks are according to the Water Pollution Prevention Law. (regulatory value of BOD is the max. concentration)

- Discharge point: Goten River

Air pollutants (NOx, SOx)

Move the screen to the left or right to see the table information

| Substance | NOx | SOx |

|---|---|---|

| Amount of emission (t/year) | 55 | ― |

| Facility | Substance | Regulatory values | Voluntary standard values | FY2022 results | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Mishima Plant Cogeneration |

NOx*1(ppm) Soot and dust (g/m3N) |

100 0.05 |

80 0.01 |

54 0.005 |

62 0.005 |

47 0.005 |

| Mishima Plant Boiler | NOx*2(ppm) Soot and dust (g/m3N) |

130 0.1 |

65 0.02 |

29 0.005 |

37 0.005 |

20 0.005 |

- According to the Air Pollution Prevention Law and recommended values set by Mishima City.

- 1 Data are expressed based on a 16% oxygen content conversion value.

- 2 Data are expressed based on a 5% oxygen content conversion value.

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

The Mishima Plant verifies whether secondary materials and auxiliary materials contain chemical substances subject to Safety Data Sheet (SDS) requirements, and in the case of substances where the amounts handled exceed the thresholds specified by the PRTR Law, annual reports are submitted to the national (or prefectural) authorities and safety impact assessment is performed.

Regarding the handling of substances pursuant to the PRTR Law, please refer to the Safety Evaluation Table of Domestic Production Bases.

Fair Operating Practices

Relationship with business partners

In 2022, due to COVID-19 infection prevention measures, we did not hold a CSR study session with our suppliers. We sent the revised version of the CSR Procurement Guidelines to our suppliers and collected signatures of approval.

- Date: November 17th to the end of December 2022

- Target: 102 companies that do business with the Mishima Plant

- Main revision details:

- Added items on the three pillars of the environment (carbon neutrality, circular economy, coexistence with nature)

- Some additions to human rights, compliance, environment, local communities, and information disclosure

We received responses from 99 companies that understood Yokohama Rubber's CSR and procurement policies and agreed with our commitment to ''build relationships of trust with our business partners based on fair and impartial transactions, and strive for mutual prosperity and mutual development.'' .

Consumer Issues

Communication with customers

To customers who tour the plant, we introduce our acquisition of the Automotive Industry Quality Management System Standard ISO/TS 16949.

Furthermore, in response to inquiries received from customers to whom we have delivered products, we make reports to them based on our quick investigation of the relevant matters.

Community Involvement and Development

Responses to comments and complaints received

We have held plant visits for local residents and environmental monitors twice a year (spring and fall), and explained our environmental initiatives to them. In fiscal 2022, we distributed a CSR site report with the participation of four people to prevent the spread of COVID-19 infection.

Thanks to effective explanations of the Mishima Plant’s environmental measures and a willingness to listen to local residents’ views, in 2022 there were no complaints from local residents.

Relationship with local societies

- We used to participate in the annual cleanup service work at Rakujyuen, a public park in Mishima City organized by the Mishima District Environmental Preservation Promotion Council, but in 2022 we participated in a small group to prevent the spread of COVID-19 infection.(Held twice a year, in May and October; canceled due to rain in May, 30 participants in October)

- In FY2022, the use of gymnasiums and the premises of dormitories for single employees located within the business sites was also banned from last year as a measure to prevent the spread of COVID-19 infection.In 2021, 0 gymnasiums and 0 bachelor dormitory grounds have been leased to local residents.

- In 2022, 0 gymnasiums and 0 bachelor dormitory grounds have been leased to local residents.

- Blood donations cooperation is held twice a year at the plant, and employees as well as people related to partner companies donate blood; however, in fiscal 2022, we suspended this activity to prevent the spread of COVID-19.

- As a business that cooperates with the fire brigade, seven of our employees are registered with the Mishima City Fire Brigade as special function members. These employees continued to be available to respond to fires in the community.

Plant tours and workshops

In FY2022, we accepted 10 plant tours, with a total of 89 visitors (up 54 from the previous year) touring the Mishima Plant.

Since Jun 2022, we have resumed small-scale factory tours exclusively for those living in Shizuoka Prefecture.

Plant Tour Information

When: Plant tours are offered on days on which the plant is in operation (Mondays to Fridays).

Excludes year-end and New Year holidays and the consecutive holiday periods in May and August.

Hours: 8:00 a.m. to 4:00 p.m.

Contact: Mishima Plant, Operation Section Tel: +81-55-975-0800

- 1. Please note that we may not be able to accept applicants depending on the usage status of the conference room or the schedule of the person in charge of acceptance.