Mie Plant (MP)

Production of tires for trucks and buses, passenger cars

Total site area264,000 m2 ABINC→259,411m2

Number of employees1,320 (as of December 2022)

Location1038 Takabuku, Misono-cho, Ise City, Mie 516-8530, JAPAN

Contact for consultation and complaintsOperation Section

Tel: +81-596-28-3151 Fax: +81-596-28-3156

E-mail: katsuharu.omi@y-yokohama.com

Message from the General Manager

Mitsugi Dairaku

Yokohama Rubber has established “Deal fairly with society and value harmony with the environment” as its basic environmental policy, and it aims to be “a company having world-class strengths in technologies for protecting the environment.” Our Mie Plant is located in Ise City: the divine capital located along the Miya River, Japan’s purest river. In doing business in this region, we have a strong desire to protect this abundance of nature and to continue to develop together with the community.

Since our plant’s acquisition of ISO 14001 certification in 1998, we have addressed environmental preservation through the full participation of our employees, such activities being centered upon our environmental management systems. Concerning preservation of the environment, we have conducted ongoing improvements due to the establishment each year of objectives for reducing environmental burdens. Special activities that we can be particularly proud of include the operational improvements and reductions with respect to resource usage amounts achieved by the “Waste Elimination Force,” a group mainly comprised of female employees, and the efforts of the “Frontline Support Team,” who have helped to transform support so that we can view manufacturing sites through the eyes of the customer. Furthermore, through the activities of the “Forever Forest Project” and we have also concluded a new “Kigyo no Mori (the forests created by companies)” initiatives with Watarai Town, Watarai District, Mie Prefecture from fiscal 2021. We have been creating forests and ensuring the conservation of water sources, such factors being valuable in the reduction of CO2, disaster-prevention and the protection of living creatures. The total number of trees planted thus far reached 30,627 with the 15th planting of seedlings in fiscal 2022.

For the biodiversity conservation activities that we have been conducting since 2012, each team implemented a scaled-down version of the activities while taking measures against infection with COVID-19. Each team continued to enjoy their own activities while also preparing their own illustrated books of organisms and plants that they created.

In January 2016, we signed an agreement between Yokohama Rubber Mie Plant and Ise City regarding environmental education and have been working on it.

The tripartite collaboration of the Mie Plant's plant tour, tree-planting experience, biodiversity conservation activities, and Mie Kotsu's "Electric Bus Ride Experience and Lecture on Building a Low-Carbon Society" for five elementary schools in Ise City was abandoned due to COVID-19.

In addition, the Mie Plant employees' volunteer activities to support the reconstruction of Onagawa Town, Oshika District, Miyagi Prefecture, which started immediately after the Great East Japan Earthquake, have come to a standstill due to COVID-19.

Furthermore, the activities of local volunteers, along with those of the municipal government and residents' associations, are at a standstill.

These activities will be resumed while checking on the status of COVID-19. We will continue our efforts to be a plant that is loved and trusted by people in the region.

Organizational Governance

Thorough compliance policies

All Mie Plant employees are issued with “compliance cards” and are familiarized with the Yokohama Rubber Group compliance guidelines, and with the availability of contact points for discussing compliance-related issues.

Compliance committee meetings made up of managers are held monthly to share information and consider and implement stratified training.

Organizational self-corrective functions

We established a suggestions box in the plant’s cafeteria, enabling us to receive feedback from employees. In addition, as we continue to operate the employees' web-based consultation service, which was established independently by the Mie Branch of the labor union, we carefully handle the opinions and requests we receive and continue to work with the Mie Branch of the labor union to make the service useful for the sound management of the organization.

Furthermore, we have started compliance training for all employees at least once a year.

Human Rights

Education on respect for human rights

We distribute “compliance cards” to employees to provide education on the importance of respect of human rights.

Labor Practices

The basics of safety and health

The Mie Plant obtained Occupational Safety and Health Management System (OSHMS) certification in accordance with Japan Industrial Safety & Health Association (JISHA) standards in 2006. This system is based on risk reduction and improvement activities in pursuit of intrinsic safety of equipment, as well as the creation of safe human resources with an emphasis on communication.

With respect to the safety and health policy of the plant, the basis of operation is as follows. "The basis of our corporate activities is to ensure the safety and health of our workers”, and “To prevent occupational accidents and realize workplaces where employees can work comfortably in good physical and mental health, we will prioritize the safety and health of each and every employee by appropriately and effectively implementing and operating the occupational health and safety management system together with our employees”.

Creating safe equipment

Using risk assessment methods, we are promoting the identification, evaluation and improvement of potential danger sources; we are also implementing measures that include the isolation of sources for danger from work areas and promoting the creation of people-friendly facilities.

Safety awareness

We pursue safety as a top priority under all circumstances. Specifically, we have shifted from collective guidance to individual guidance, and we conduct one-on-one safety education, dedicated safety time activities, and reviews of work procedures in open work observation.

In addition, we view successor development as a priority issue, and we are working to improve skills through various types of training.

We conduct activities suitable for the mind of each and every individual through thorough decluttering and organizing and the revitalization of communication.

Creating energetic workplaces

We give a variety of different awards even for small achievements. We do this irrespective of what job titles recipients hold. Numerous improvement suggestions from the factory floors have been successfully developed into safety enhancement measures by encouraging people to challenge themselves, rather than fear failure.

As part of our efforts to promote health, we have introduced a health app to help each and every employee work in good health.

By planning and participating in "walking events" linked to the app to improve health, participants can have fun while becoming more aware of their own health and improving lifestyle-related diseases.

Additionally, in order to reduce the smoking rate among employees, we set a smoking rate of 49.7% in 2016 as a reference point, and have been implementing various initiatives since then.

We set a no-smoking day three mornings a month, and also planned a six-month no-smoking project aimed at reducing the smoking rate, resulting in a smoking rate of 43.2%.

In 2023, we plan to continue the activities, extend the time of the non-smoking day, and make people aware of the harmful effects of smoking in order to reduce the smoking rate.

As part of our local activities, we collaborated with the Ise Labor Standards Inspection Office and the local soccer club team FC-ISE-SIMA to disseminate fall prevention exercises to prevent falls and back pain, and soccer players conducted safety patrols at the Mie Plant.

We disseminate safety activities to the local community through publications in the Ise Labor Standards Inspection Office's official bulletin and mass media.

Employment of people with disabilities

Regarding the employment of people with disabilities, we continue to hold internships in order to deepen our relationships with local special needs schools. In 2022, due to the COVID-19 pandemic, we will only accept one time (one person). However, we were able to hire one person.

The Environment

Environmental management

Our goal is to embody consideration towards the global environment according to the norm of “Deal fairly with society and value harmony with the environment,” which is declared in the management policy of the company.

- The Mie Plant, under the direction of senior management, works on measures taking the environment into consideration in all areas of our business.

- The Mie Plant works to deepen channels of communication with its stakeholders; it also promotes cooperation with the value chain and contributes to both the local community and society.

- In order to remain trusted by the community, we appropriately implement our environmental management system and continue our efforts to prevent environmental pollution and improve the environment.In addition, we will continue to reduce our environmental impact through chemical substance management, aiming for zero environmental risk.

We observe applicable laws, regulations and agreements. - We comply with related laws, regulations, agreements, etc., and continuously engage in environmental improvement activities.

- To maintain biodiversity, we strive to protect and revitalize the indispensable nature of the local ecosystem and the Miya River which runs into Ise Bay, and we also participate actively in community environmental activities.

- Aiming to maintain the trust of the local community by fostering harmony with the natural wonders of the divine capital of Ise, all of us working at the Mie Plant implement education and awareness raising.

- We shall value information from residents when carrying out regular plant improvements.

- To fully realize our environmental policy, we formulate environmental objectives and targets and draw up and implement environmental plans.

- This Environmental Policy shall be made public.

January 1, 2023

Mitsugi Dairaku,

General Manager,

Mie Plant, The Yokohama Rubber Co., Ltd.

Environmental data

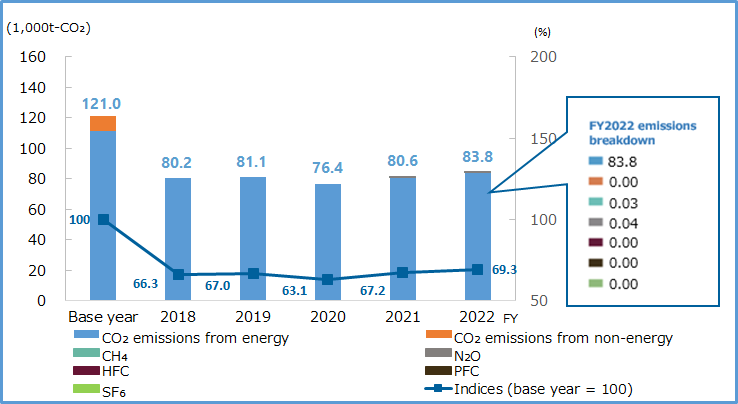

Reductions in greenhouse gas emissions

Greenhouse gas emissions

- The base year is de¬ned as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Method of calculation of greenhouse gases (GHG): this is in compliance with the “Calculation and Reporting Manual for Greenhouse Gas Emissions” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Note that GHG emissions associated with purchased power were calculated using the Table of Emission Coeffi¬cients by Power Company (Ministry of the Environment).

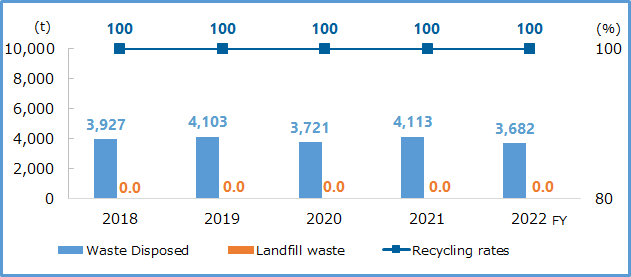

Effective use of resources / Reduction of waste

Waste output

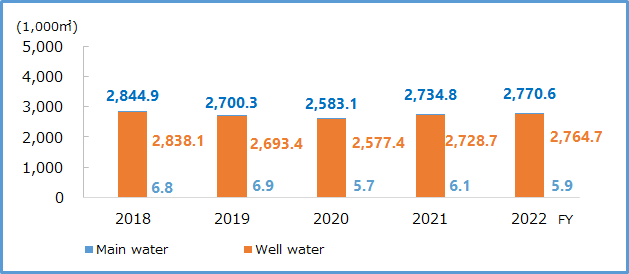

Water usage

Measures for discharge into water, air and soil

Data related to water contamination

Move the screen to the left or right to see the table information

| Drain | Item | Regulatory values | Voluntary standard values | FY2022 results | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Mie Plant Drain 1 | pH | 6.0~8.0 | 6.5~7.8 | 7.3 | 7.5 | 7.2 |

| BOD concentration (mg/l) | 20 | 5 | 1.4 | 2.8 | 0.7 | |

| COD concentration (mg/l) | 20 | 5 | 1.5 | 2.8 | 0.7 | |

| SS concentration (mg/l) | 40 | 5 | 1.3 | 2 | 1 | |

| Oil concentration (mg/l) | 2 | 1.6 | 0.5 | 1 | 0.5 | |

| Mie Plant Drain 2 | pH | 6.0~8.0 | 6.5~7.8 | 7.3 | 7.4 | 7.2 |

| BOD concentration (mg/l) | 20 | 5 | 1 | 4.4 | 0.5 | |

| COD concentration (mg/l) | 20 | 5 | 1.6 | 3.6 | 0.5 | |

| SS concentration (mg/l) | 40 | 5 | 1.3 | 4 | 1 | |

| Oil concentration (mg/l) | 2 | 1.6 | 0.6 | 1.1 | 0.5 | |

- In accordance with the Environmental Pollution Prevention Agreement concluded with Ise City.

- Discharge point: Hinokijiri River

Air Pollutants (NOx, SOx)

Move the screen to the left or right to see the table information

| Substance | NOx | SOx |

|---|---|---|

| Amount of emission (t/year) | 1 | ― |

| Facility | Substance | Regulatory values | Voluntary standard values | FY2022 results | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Mie Plant Cogeneration 1 |

SOx emissions (m3N/h) NOx (ppm) Soot and dust (g/m3N) |

3.4 100 0.05 |

1 90 0.01 |

0.41 22 0.002 |

0.52 28 0.003 |

0.35 14 0.001 |

| Mie Plant Cogeneration 2 |

SOx emissions (m3N/h) NOx (ppm) Soot and dust (g/m3N) |

3.4 100 0.05 |

1 90 0.01 |

0.413 10 0.002 |

0.46 14 0.002 |

0.392 8 0.001 |

| Mie Plant Boiler 3 | SOx emissions (m3N/h) NOx (ppm) Soot and dust (g/m3N) |

1.0 130 0.1 |

1 120 0.01 |

0.02 59 0.005 |

0.02 67 0.005 |

0.02 51 0.005 |

| Mie Plant Boiler 4 | SOx emissions (m3N/h) NOx (ppm) Soot and dust (g/m3N) |

1.5 130 0.1 |

1 120 0.01 |

0.037 63 0.005 |

0.04 69 0.005 |

0.03 59 0.005 |

- In accordance with both the Air Pollution Control Act and the Environmental Protection Agreement concluded with Ise City.

Reporting on chemical substance management status

The Mie Plant verifies whether all materials handled at the plant (raw materials, secondary materials, and auxiliary materials) contain chemical substances subject to Safety Data Sheet (SDS) requirements, and in the case of substances where the amounts handled exceed the thresholds specified by the PRTR Law, annual reports are submitted to the national (or prefectural) authorities and safety impact assessment is performed. Regarding the handling of substances pursuant to the PRTR Law, please refer to the Safety Evaluation Table of Domestic Production Bases.

In addition, to enhance the overall level of chemical substance management, we conduct compliance verification by implementing chemical substance assessment that covers risk of adverse impact on employee health, risk of explosion or fire in relation to equipment and machinery, and environmental risk.

Efforts for Biodiversity Conservation Activities

At the Ominato Coast, one of our biodiversity activity bases, our employees gave an annual class for 4th graders of Minato Elementary School. The class included a talk on the creatures of the Ominato Coast, removal of non-native species of Japanese knotweed, and beach cleanup.

Coastal cleanup at a delivery class

Group photo of the delivery class

Due to COVID-19, the annual tree-planting experience and biodiversity conservation activity experience could not be held, but preparations are underway to hold these events in FY2023. We are also making preparations to hold the semi-annual activity report meeting.

Monitoring (sandy soil survey)

Sea turtle hatching survey (September)

Noise, vibration and odor

Noise

Noise management is implemented at the boundary of the premises of the plant (18 points) and autonomous measurement is conducted once a month.

In addition, measurements are conducted by an outside company twice a year at the boundaries of the factory premises (at four locations).

Vibration

Vibration management is implemented at the boundary of the premises of the plant (14 points) and autonomous measurement is conducted once a month.

Odor

Twice a year, external contractors conduct measurements at the factory site boundaries (4 locations).

Our response involves the installation of deodorizing vaporizers in building ducting.

Comments and information from local residents from the past and our response

We installed the third and fourth phases of anti-scattering nets at the site boundary to prevent leaves from trees on the plant site from being blown into neighboring residences by the wind.

We also disinfect trees in the spring and fall to prevent insects from flying into neighboring houses every year.

Fair Operating Practices

Certification of new business partners

Guidelines are established on compliance with human rights, legal compliance, and safety and environmental activities, etc. when business is to be commenced with a new business partner. Based on such points, the approval processes for the appointment of a new procurement partner are undertaken, and interviews are conducted while various materials are referred to. It is through this process that business partners are selected.

Communication with business partners

Implementation was postponed due to COVID-19.

The CSR Study Meeting was held via the web.

Consumer Issues

Safety and quality of our products and services

Using as a pillar the principle of “creating quality through the eyes of the customer,” at the Mie Plant we promote the continuous improvement of products and services by leveraging the quality management system ISO/TS 16949 (moved to ISO 9001 and IATF 16949 from June 2018) as our operational basis. We regularly confirm the effectiveness of this system through internal systems audits and external reviews that are conducted every six months.

In addition, by using “Quality Maintenance Activities” to ensure effective self-directed quality management throughout the entire production process, etc., we position quality as customer safety while working to ensure that all employees are conscious of the “eyes of the customer” being on them.

With respect to products, we are actively working to further reduce our environmental impact by increasing the production ratio of tires with reduced rolling resistance, improved wear life, superior rehabilitation, and ultra-wide base tires.

Community Involvement and Development

Relationship with local societies

Regional exchanges

We were planning to hold the event, but it was cancelled due to COVID-19.

Social contribution activities

Due to COVID-19, we had to cancel all events, but only made donations to the Ise City Council of Social Welfare, which we have done every year.

We received a report of our gratitude that they have purchased one activity vehicle using the savings they have made through continued donations.

Despite the COVID-19 pandemic in 2022, blood donations were held three times in January, May, and October, as usual, with 120 people volunteering.

Regional volunteers

May 21: Zero garbage early morning cleaning (around Oharai Town)

July 3: 27th Setagawa Tanabata Grand Cleaning

Oct 10: Exhibited at Ise City Environmental Fair

Dec 4: Volunteer water supply at the Oise-san Marathon

Opening of facilities

We have lent our grounds for use by a regional soccer club (ISE YAMATO).

Environmental activities

Feb: Acquired Association for Business Innovation in Harmony with Nature and Community (ABINC) certification

Mar 25: Corporate Forest Tree Planting

Apr 6: 15th period-1 tree planting

May 9: 15th period-1 tree planting

May 23: Cleaning of Ominato Beach in Ise City

Oct 28: Corporate Forest Tree Planting

Nov 11: Toba City Toshijima Nasa Beach Cleaning

Corporate forest tree planting

Plant tour and workshop

In fiscal 2022 as well, due to the COVID-19 pandemic, factory tours for nearby elementary schools, companies, and organizations were prohibited. As the mood of self-restraint gradually faded towards the end of the year, one company visited us.

Please contact us below if you would like to participate in a plant tour and workshop.

Holding Day: Monday to Friday (Except for year end and New Year holidays, consecutive holidays in May and August)

Hours: 8:00 a.m. to 5:00 p.m.

Contact: Sugihara, Operation Section, General Affairs

Tel: +81-596-28-3151