The Environment

Products and Services

KPI

Responsible Departments

Our position and Targets

Review of FY 2022 Activities

Introduction of Initiatives

Future challenges

KPI

Move the screen to the left or right to see the table information

| Item | FY 2021 results | FY 2022 results |

|---|---|---|

| Ratio of environmentally friendly products to all products handled | (Consolidated) 100.0% | (Consolidated) 100.0% |

| Reuse and recycling ratios for used products and packaging materials |

(Consolidated) Used products Tires 67% MB 85% Packaging materials 84% |

(Consolidated) Used products Tires 65% MB 95% Packaging materials 84% |

Responsible Departments

Product development and planning division

Our position and Targets

Why is “Environmentally Friendly Products” a critical issue to be addressed?

Explanation of the reason and background

The LCA (life cycle assessment) method enables us to understand environmental burdens (CO2 emissions) generated at each stage of product life cycle from their production to disposal. We employed this method to conduct measurements on tires, the Yokohama Rubber Group's flagship products, and found that the CO2 emissions at the use-stage accounted for 80 to 90% of the total CO2 generation in the entire life cycle. Therefore, Yokohama Rubber Group has directed efforts particularly toward "producing environment-friendly products to achieve fuel efficiency."

Our policies and position relating to products and services

In accordance with our basic position set forth in the Yokohama Rubber Basic Environmental Policy, the Yokohama Rubber Basic Environmental Policy, Yokohama Rubber Environmental Policy, and the Yokohama Rubber Group Action Guidelines, the Yokohama Rubber Group will work to prevent global warming, effectively use resources, and consider and improve chemical substance management with the aim of minimizing the burden of products and services provided by the Yokohama Rubber Group on the global environment. In addition, we will provide environment-friendly products with improved safety and quality (performance) to customers.

Vision

We will maintain a 100% ratio of "products that contribute to the environment," and improve product environmental performance responding to social demands.

Measures to pursue our vision

To be a "top-level environment friendly company," we will maintain "100% environmentally friendly product portfolio."

In the production of environmentally friendly products, we not only simply work on the reduction of green house gas emissions through our products, but also work to ensure safety and comfort through means such as resource recycling, resource conservation, and the reduction of chemical substances contained in our products. Before the development of new products, candidate products are subject to the system in which they undergo an environment impact assessment at the early stage of the development process and need to meet our Environment-Friendly Products Regulations* at the design review stage; therefore, it is right to say that all the products released from our Group are environmentally friendly products.

In the production of environmentally friendly products, we not only simply work on the reduction of green house gas emissions through our products, but also work to ensure safety and comfort through means such as resource recycling, resource conservation, and the reduction of chemical substances contained in our products. Before the development of new products, candidate products are subject to the system in which they undergo an environment impact assessment at the early stage of the development process and need to meet our Environment-Friendly Products Regulations* at the design review stage; therefore, it is right to say that all the products released from our Group are environmentally friendly products.

- Environment-Friendly Products Regulations: Newly developed products are required to exceed conventional products by 5% or more in terms of the average scores of the four items of "prevention of global warming," "recycling and circulation of resources," "resource conservation," and "safety and comfort" with no decrease found in any of the items.

<Four pillars of environmental performances and environmental performance evaluation index>

Review of FY 2022 Activities

Results for the environmental contribution ratio (overall)

The ratio of environmentally friendly products in the Yokohama Rubber Group has remained at 100.0% since 2017. The ratio of fuel-efficient tires sold in FY2022 (consolidated) was 35.9%.

It has been calculated that the use of fuel-efficient tires led to the reduction of approximately 1,748 thousand t-CO2 emissions in terms of "GHG emissions at the product use stage" (Scope 3), which are indirect emissions in the supply chain. In the development of enironmentally friendly products, the results of the degree of their environmental contribution and environmental impact were not evaluated.

It has been calculated that the use of fuel-efficient tires led to the reduction of approximately 1,748 thousand t-CO2 emissions in terms of "GHG emissions at the product use stage" (Scope 3), which are indirect emissions in the supply chain. In the development of enironmentally friendly products, the results of the degree of their environmental contribution and environmental impact were not evaluated.

Introduction of Initiatives

High-pressure hydrogen gas hoses (ibar HG82)

For a hydrogen infrastructure to be successfully spread in society, it is vital to develop pressure-tight, durable, lightweight, and flexible hoses.

Yokohama Rubber has newly developed reinforced hybrid structure utilizing PBO fiber and steel wire, and launched products that meet these requirements.

Yokohama Rubber has newly developed reinforced hybrid structure utilizing PBO fiber and steel wire, and launched products that meet these requirements.

"BluEarth-GT AE51" fuel-efficient tires

Fuel efficiency has been further improved while ensuring the excellent wet grip performance well-established by our previous product (BluEarth-A). In the domestic labeling system, their wet grip performance has received the highest grade of “a” for all sizes. In terms of rolling resistance performance, BluEarth-GT AE51 has acquired “AA” for size 31 and “A” for size 26.

"ice GUARD SUV G075" studless tires for SUVs

While realizing the "iceGUARD" series basic concepts of "being effective on icy surfaces," "being long-lasting" and "improving fuel consumption," they adopt "low-heat-generating tread rubber" using the technology developed for the fuel efficient tire brand "BluEarth" in terms of "improving fuel consumption" to reduce energy loss due to heat generation and reduce rolling resistance by 5%. Furthermore, by optimizing the tread arrangement using Yokohama Rubber's original simulation technology, pattern noise has been reduced by 28% (compared in noise energy reduction rate) to improve quietness.

"BluEarth 711L" fuel efficient performance-oriented all-season truck tires

"BluEarth 711L" has achieved the highest fuel economy performance in the history of YOKOHAMA's truck tires. This performance improvement will greatly reduce transportation costs beard by our customers who often drive long distances on motorways. This product was created with new compound composition and YOKOHAMA's unique blending technique, in addition to the newly developed tread pattern with increased rigidity, the product of advanced technology, achieving 42% reduction in rolling resistance compared with "710R," our company's all-season tires.

"BluEarth 711L" is the first product bearing the name of "BluEarth," the fuel-efficient tire bland, as domestic tires for heavy trucks.

"BluEarth 711L" is the first product bearing the name of "BluEarth," the fuel-efficient tire bland, as domestic tires for heavy trucks.

"ECOTEX" energy-saving conveyor belt

We delivered an energy-saving conveyor belt called "ECOTEX," the longest conveyor line in Japan (about 14km), to the KLT line of Chichibu Taiheiyo Cement Corporation. In addition to having its excellent durability, ECOTEX contributes to reducing the energy consumption of conveyors by optimizing the viscoelasticity of the bottom cover rubber in contact with the roller, and reducing the running-over resistance of the roller. The KLT line has achieved a significant reduction in energy consumption of more than 50% (according to our research) after the delivery compared with our conventional products. After this replacement, Chichibu Taiheiyo Cement Corporation was also awarded the "Limestone Association of Japan’s Best Achievement Award" at the 77th Limestone Mining Convention, by which "ECOTEX" won the admiration for its energy-saving performance.

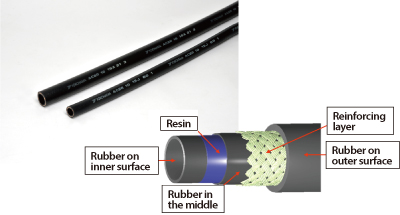

Car air-conditioner hoses compatible with next-generation coolant

We have developed car air-conditioner hoses compatible with HFO-1234yf, which has come to be widely used by car manufacturers in North America as a next-generation coolant for car air-conditioners. The high-pressure and low-pressure hoses newly developed this time have already been adopted.

HFC-134a, now widely used as a coolant for car air-conditioners, has a high-degree of impact on global warming with its global warming potential (GWP) being 1,430; however, the GWP of HFO-1234yf is controlled to be at four, and there is a movement to promote switching from a viewpoint of the prevention of global warming. However, HFO-1234yf has the property of decomposing gradually with long-term use and generating acid, which posed the problem of causing resin corrosion when a hose having a resin layer on its innermost surface was used. It was possible to solve this problem either by improving the resin material, or preventing contact between the resin and coolant. However, to meet the demands of car manufacturers in North America, we decided to adopt a hose structure with a rubber layer on the inner surface of the resin layer, and developed an internal rubber with improved adhesion, which led to the development of a car air-conditioner hose that prevents direct contact between coolant and the resin, as well as resin corrosion and coolant leakage.

HFC-134a, now widely used as a coolant for car air-conditioners, has a high-degree of impact on global warming with its global warming potential (GWP) being 1,430; however, the GWP of HFO-1234yf is controlled to be at four, and there is a movement to promote switching from a viewpoint of the prevention of global warming. However, HFO-1234yf has the property of decomposing gradually with long-term use and generating acid, which posed the problem of causing resin corrosion when a hose having a resin layer on its innermost surface was used. It was possible to solve this problem either by improving the resin material, or preventing contact between the resin and coolant. However, to meet the demands of car manufacturers in North America, we decided to adopt a hose structure with a rubber layer on the inner surface of the resin layer, and developed an internal rubber with improved adhesion, which led to the development of a car air-conditioner hose that prevents direct contact between coolant and the resin, as well as resin corrosion and coolant leakage.

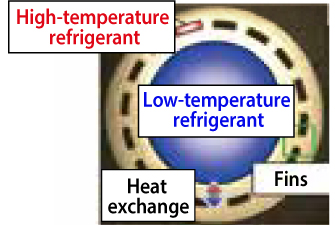

Internal heat exchanger (IHX) that improves cooling efficiency of car air conditioners

We have developed a double-tube IHX*1 that improves the cooling efficiency of car air conditioning systems.

Currently, HFC-134a, which is widely used as a coolant in car air conditioners, has a high GWP*2 of 1,430, so the switch to HFO-1234yf (GWP = 4) with a low coefficient is progressing to prevent global warming. On the other hand, while the cooling efficiency of HFO-1234yf is lower than for HFC-134a, the developed double-tube internal heat exchanger can cover this drop in cooling efficiency. With a double-tube structure that integrates a part of two coolant tubes that were conventionally configured separately and using the temperature difference between the high-temperature and low-temperature coolants to exchange internal heat, it improves the cooling efficiency of the entire air conditioning system (Fig. 1). In addition, it was necessary to design the pipes according to the layout of the engine room since the car air conditioning system is piped in a narrow space there, but the piping could be designed freely as with conventional air conditioning by arranging the fins inside (Fig. 2) since the coolant flow path is not crushed even if it is bent. The newly developed double-tube internal heat exchanger has already been adopted.

Currently, HFC-134a, which is widely used as a coolant in car air conditioners, has a high GWP*2 of 1,430, so the switch to HFO-1234yf (GWP = 4) with a low coefficient is progressing to prevent global warming. On the other hand, while the cooling efficiency of HFO-1234yf is lower than for HFC-134a, the developed double-tube internal heat exchanger can cover this drop in cooling efficiency. With a double-tube structure that integrates a part of two coolant tubes that were conventionally configured separately and using the temperature difference between the high-temperature and low-temperature coolants to exchange internal heat, it improves the cooling efficiency of the entire air conditioning system (Fig. 1). In addition, it was necessary to design the pipes according to the layout of the engine room since the car air conditioning system is piped in a narrow space there, but the piping could be designed freely as with conventional air conditioning by arranging the fins inside (Fig. 2) since the coolant flow path is not crushed even if it is bent. The newly developed double-tube internal heat exchanger has already been adopted.

- 1:IHX=Internal Heat Exchanger

- 2:GWP=Global Warming Potential

(Fig. 1) Car air conditioning system using double-tube internal heat exchanger

(Fig. 2) Cross section of pipe with finned double-tube structure

"BluEarth-air EF21" light weight fuel-efficient tires

We have developed "BluEarth-air EF21," advanced technology concept tires that aim to contribute to the environment with its latest lightweight design.

"BluEarth-air EF21" adopts Yokohama's latest lightweight design technology with the aim of contributing to the reduction of total vehicle weight for the improvement of fuel efficiency and contributing to the environment through the reduction of necessary materials. By this, we achieved a lightweight, thin and highly rigid structure with a weight reduction of about 25% in mass. It also adopts a newly developed exclusive compound and "A.R.T. Mixing," the latest rubber mixing technology. BluEarth-air EF21 has received the highest grade of "AAA" for its rolling resistance performance, and its wet grip performance also has received the highest grade of "a" exhibiting excellent fuel efficiency and wet performance.

"BluEarth-air EF21" was developed in commemoration of the Yokohama Rubber’s 100th anniversary, and was sold with a production limit of 100 in December 2017.

Its performance has been inherited by "BluEarth-1 EF20."

"BluEarth-air EF21" adopts Yokohama's latest lightweight design technology with the aim of contributing to the reduction of total vehicle weight for the improvement of fuel efficiency and contributing to the environment through the reduction of necessary materials. By this, we achieved a lightweight, thin and highly rigid structure with a weight reduction of about 25% in mass. It also adopts a newly developed exclusive compound and "A.R.T. Mixing," the latest rubber mixing technology. BluEarth-air EF21 has received the highest grade of "AAA" for its rolling resistance performance, and its wet grip performance also has received the highest grade of "a" exhibiting excellent fuel efficiency and wet performance.

"BluEarth-air EF21" was developed in commemoration of the Yokohama Rubber’s 100th anniversary, and was sold with a production limit of 100 in December 2017.

Its performance has been inherited by "BluEarth-1 EF20."

Future challenges

One of the challenges we are facing is the handling of old products that are difficult to be replaced with new products due to promises made to customers.

For other products, at the end of FY2017, we achieved 100% ratio of products that contribute to the environment sold in Japan and overseas. We are determined to continue to maintain a 100% ratio of products that contribute to the environment and enhance activities to further improve the environment.

For other products, at the end of FY2017, we achieved 100% ratio of products that contribute to the environment sold in Japan and overseas. We are determined to continue to maintain a 100% ratio of products that contribute to the environment and enhance activities to further improve the environment.