The Environment

Emissions

KPI

Responsible Departments

Our position and Targets

Review of FY 2022 Activities

Introduction of Initiatives

Future challenges

KPI

Move the screen to the left or right to see the table information

| Item | FY 2021 results | FY 2022 results |

|---|---|---|

| Emissions of greenhouse gases |

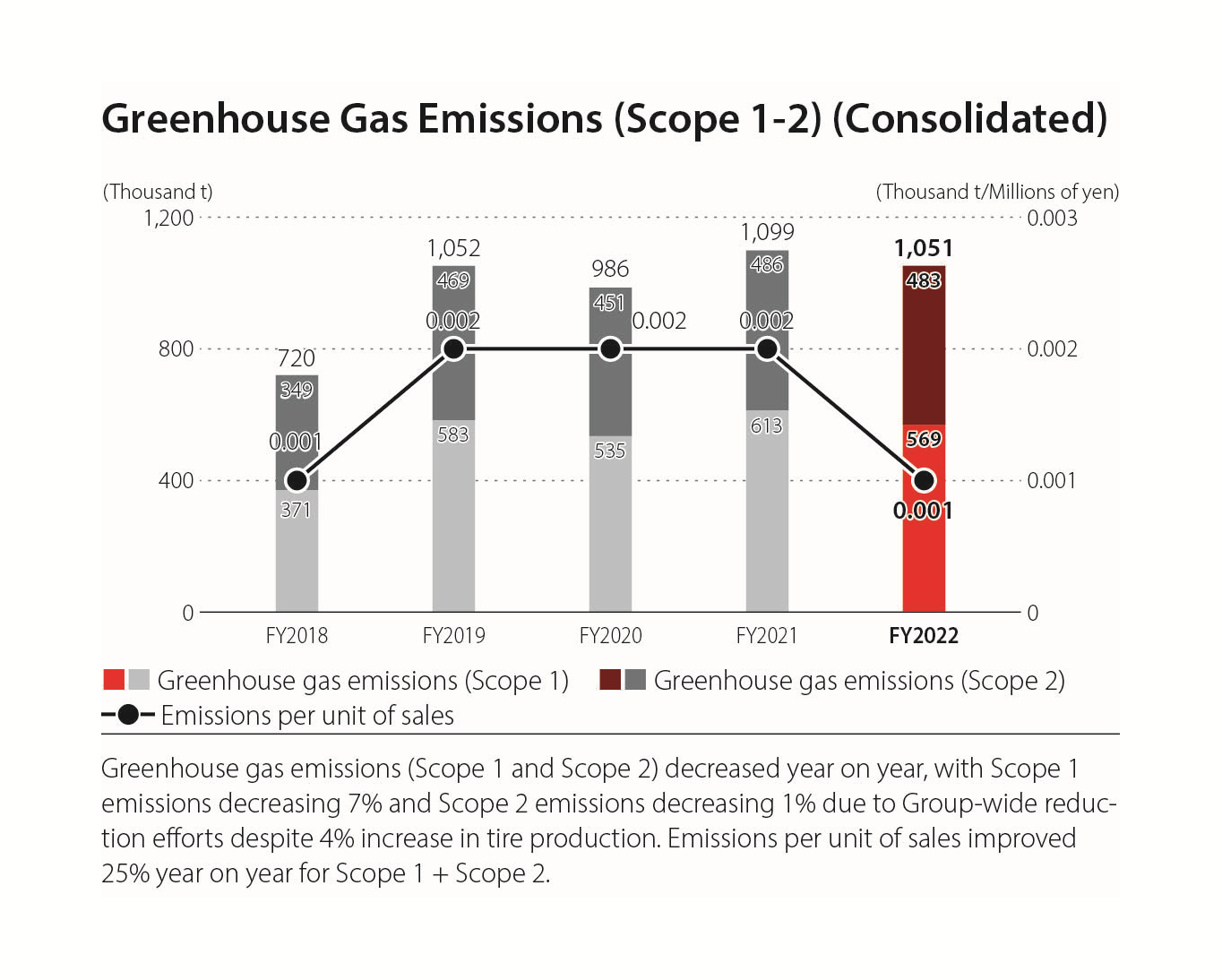

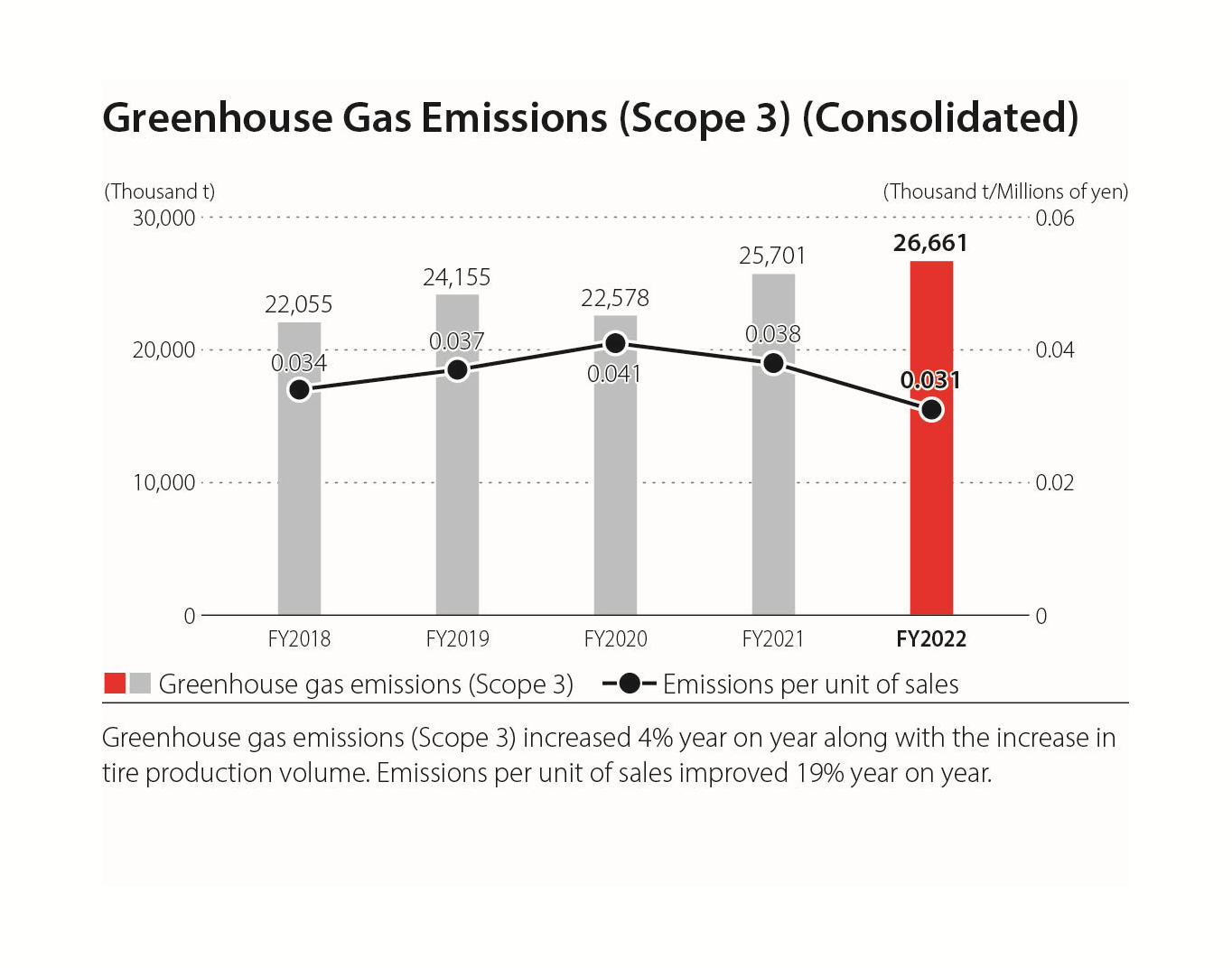

(Consolidated) Scope1 613 thousand tons Scope2 486 thousand tons Scope3 25,701 thousand tons |

(Consolidated) Scope1 569 thousand tons Scope2 483 thousand tons Scope3 26,661 thousand tons |

| Ozone-depleting substances | Emissions of CFCs (Non-consolidated) 678 tons (Domestic) 956 tons |

Emissions of CFCs (Non-consolidated) 1,263 tons (Domestic) 1,356 tons |

| HAPs (Hazardous Air Pollutants) | (Domestic) 17.3 tons | (Domestic) 12.3 tons |

Responsible Departments

Each business location

- Activities are conducted by each location, and the direction of policies and activity measures are decided on by bodies that include the Global Warming Countermeasures Committee and the Chemical Substance Management Committee.

- In 2022, the Global Warming Countermeasures Committee has been reorganized into the Carbon Neutral Committee.

Our position and Targets

Why is “Emissions” a critical issue to be addressed?

Explanation of the reason and background

We use resources to manufacture and sell various rubber products such as tires, hoses, and belts. In particular, we recognize that reducing the amount of emission in the manufacturing process and the use-phase is a particularly important initiative that will lead to the prevention of global warming and environmental pollution, as well as continuous business operation at each site.

Our policies and position relating to emission

The Yokohama Rubber Group will work to minimize the burden on the environment by providing products and services in accordance with the "Yokohama Rubber Environmental Policy" and the "Yokohama Rubber Group Action Guidelines".

To this end, we will develop and introduce environmental technologies while working together with various people involved in the provision of products and services to promote the reduction of emissions into the atmosphere throughout the entire value chain.

We are determined to control the emissions not only by complying with international agreements on emission, and the regulations of each country, such as the Energy Conservation Act, the Act on Promotion of Global Warming Countermeasures in Japan, and regulation-responding policies from related organizations such as the Japan Rubber Manufacturers Association, but also by voluntarily setting even stricter standards.

To this end, we will develop and introduce environmental technologies while working together with various people involved in the provision of products and services to promote the reduction of emissions into the atmosphere throughout the entire value chain.

We are determined to control the emissions not only by complying with international agreements on emission, and the regulations of each country, such as the Energy Conservation Act, the Act on Promotion of Global Warming Countermeasures in Japan, and regulation-responding policies from related organizations such as the Japan Rubber Manufacturers Association, but also by voluntarily setting even stricter standards.

Risks and opportunities of the Yokohama Rubber Group associated with greenhouse gas emissions

<Risks>

Risks include an increase in facility investment costs for emissions reduction, an increase in energy costs related to the use of renewable energy, and an increase in investment costs necessary to deal with the deterioration in working environments due to global warming as well as to take countermeasures.

<Opportunities>

By the reduction of emissions the atmosphere, we contribute to society through promoting the efficient use of energy necessary for operation, conserving the environment of the areas we operate our business, and externally providing heat-insulating materials, etc. Controlling not only the emissions of greenhouse gas but also those of volatile organic compounds (VOCs) and air pollutants makes it possible to reduce the cost of environment-related investment, which will leads to a reduction in product manufacturing costs.

Use of offsets

Offsets are not used.

Vision (attainment goal) / target

As international regulations related to emissions become increasingly stringent, as a general rule we aim to achieve control standards equivalent to those of the developed economies.

The Yokohama Group is working to reduce total greenhouse gas (GHG) emissions as an energy use reduction target.

The Yokohama Group is working to reduce total greenhouse gas (GHG) emissions as an energy use reduction target.

- Long-term target:

- Achieve net zero CO2 emissions (carbon neutrality) in our activities by 2050

- Mid-term target:

- Reduce CO2 emissions from company activities by 38% by 2030 compared to fiscal 2013

*This activity is on the same level as our goal of a 28% reduction by 2030 (compared to 2019). - Encourage suppliers to collaborate with us in meeting our targets.

- Reduce CO2 emissions from company activities by 38% by 2030 compared to fiscal 2013

Measures for vision achievement

Our Group conducts the following measures to monitor and reduce the environmental burdens generated throughout our activities including production activities, R&D, and office work.

- We set voluntary control criteria that are stricter than those required by laws and regulations and constantly conduct monitoring.

- We regularly report legally-required measurement results to government authorities and local residents.

- We enhance activities toward the reduction of environmental burdens, such as one for the improvement of our production process.

We promote the switch of energy source to be used, the introduction of renewable energy, the control of exhaust heat with heat retention and insulation materials, and the introduction of the latest environmental technologies and systems. - Prevention of environmental pollution

We identify environmental pollution risks and take remedial measures accordingly, and regularly implement monitoring and measurements, etc. - Chemical substance management

We ascertain the suitability of chemical substances contained in materials to be used in our products at the time of adoption or when laws and regulations are changed.

We minimize the use of environmentally hazardous substances in our business activities and products, and control the emissions of VOCs and hazardous substances.

Review of FY 2022 Activities

Greenhouse Gas (GHG) Emissions

Response to climate change (Disclose information on TCFD)Greenhouse Gas Emissions (Scope 1-2) (Consolidated)

Scope 3 estimation

Greenhouse Gas Emissions (Scope 3) (Consolidated)

Scope 3 covers the calculation of 13 categories. Scope 3 accounts for 96.2% of all categories from Scope 1 to 3 combined, in which "Use of products" accounts for 76.1%. Our Company will endeavor to spread environmentally friendly products and fuel efficient tires while making concerted efforts with our suppliers to promote the reduction of GHG emissions in our value chain.

Move the screen to the left or right to see the table information

(Emissions Unit: thousand t-CO2)

| Cat | Scope 3 category | FY2020 | FY2021 | FY2022 |

|---|---|---|---|---|

| 1 | Purchased products and services | 2,924 | 4,031 | 4,022 |

| 2 | Capital goods | 52 | 152 | 175 |

| 3 | Fuel and energy | 135 | 147 | 129 |

| 4 | Transportation and distribution (upstream) | 167 | 154 | 125 |

| 5 | Waste | 16 | 50 | 27 |

| 6 | Business travel | 3 | 5 | 5 |

| 7 | Commuting employees | 20 | 21 | 19 |

| 8 | Upstream lease assets | NA | NA | NA |

| 9 | Downstream transportation and distribution | 59 | 72 | 59 |

| 10 | Processing of sold products | 11 | 10 | 14 |

| 11 | Use of products | 18,259 | 19,940 | 21,087 |

| 12 | Disposal of products | 822 | 875 | 906 |

| 13 | Downstream lease assets | NA | NA | NA |

| 14 | Franchise | NA | NA | NA |

| 15 | Investment | 111 | 246 | 92 |

| SUM | 22,578 | 25,701 | 26,661 |

- 1 Scope 1: Direct emissions of greenhouse gases by the Company (examples: fossil fuel, natural gas, etc.)

- 2 Scope 2: Indirect emissions of greenhouse gases by the Company (electric power use, etc.)

- 3 Scope 3: Greenhouse gases emitted indirectly by the Company through its supply chain activities (manufacturing, transportation, business travel, commuting, etc.)

- 4 Calculation was conducted in accordance with the criteria of Scope 3 issued by the "GHG Protocol."

Verification of greenhouse gas (GHG) emissions

We had the calculation results verified by a third-party institution in order to ensure the accuracy and reliability of our GHG emission calculation.

- Third-party greenhouse gas verification report

Emissions of NOx, SOx, etc.

There was no occurrence of events leading to air pollution.

The emission concentrations of NOx and SOx are controlled to comply with legal regulations on concentration values.

The emission concentrations of NOx and SOx are controlled to comply with legal regulations on concentration values.

(Domestic) (Unit: tons)

| Cat | NOx | SOx |

|---|---|---|

| FY 2021 | 111.8 | 3.3 |

| FY 2022 | 98.4 | 3.7 |

Regarding the use and emission of ozone-depleting substances, we use class I specified products, such as air-conditioning facilities, which includes the use of chlorofluorocarbon. In FY2022, since following the updating of equipment, a lot of waste was disposed, we registered our leak level. There were no cases of dioxin emission.

Even though the amount of VOC emission increased overseas due to increase in production, the total amount decreased by 1.7% compared with the previous year.

Even though the amount of VOC emission increased overseas due to increase in production, the total amount decreased by 1.7% compared with the previous year.

Introduction of Initiatives

Switch of energy source to natural gas

We have been promoting the switch of the fuel used in domestic plants to gas that is supplied via environment-friendly gas pipelines. Effort has been made even in some countries where a gas pipeline system has not been fully developed. For example, the Vietnam Plant has switched from heavy fuel oil to gas by using tank lorries to transport it, and the India Plant has also switched from heavy fuel oil to gas by using gas cylinder, both of which has contributed to the reduction of CO2 emissions.

Switch to gas cylinders in the India Plant

Switch to gas cylinders in the India Plant

Installation of solar lights

Street lights combining a high efficiency solar panel and LEDs have been installed.

Since using an independent power supply, the street lights will be effective even in the event of a disaster or power outage.

Since using an independent power supply, the street lights will be effective even in the event of a disaster or power outage.

Installation of solar street lights

Installation of solar and wind powered street lights

Employing heat recovery technology to utilize factories’ waste heat for air-conditioning (absorption chilling equipment)

Employing the absorption chilling equipment with a heat recovery system to use waste heat, etc. has contributed to the reduction of CO2 emissions as well as to the reduction of power consumption during peak time during summer months.

Absorption chilling equipment

Steam driven compressor

The plant gets air supply by operating the air compressor powered by the energy generated from the pressure difference resulting from steam decompression, which has never been used before.

Showing results in cutting down power consumption and CO2 emission.

Showing results in cutting down power consumption and CO2 emission.

Steam driven compressor

Energy saving improvements through heat insulation materials

We manufacture and install heat insulation materials fitting the size of equipment and piping.

We are implementing energy-saving activities that control heat release by installing heat insulation materials on and near steam pipework in our business locations both in Japan and overseas.

We are implementing energy-saving activities that control heat release by installing heat insulation materials on and near steam pipework in our business locations both in Japan and overseas.

Pipe insulation

Energy-Saving Technology Committee

We have held Energy-Saving Technology Committee meetings to promote the adoption of energy management methods conforming to the Energy Conservation Act and the introduction of energy-saving equipment, which has led to the effective reduction of energy consumption.

Energy-Saving Technology Committee

We are also promoting energy-saving activities from a management perspective.

- Promote in-house black illumination, encouraging employees to leave work on time.

- Promote a cool biz campaign in summer and a warm biz campaign in winter in-house for energy saving.

- Make sure to turn off office automation equipment when they are not being used to reduce standby power consumption.

- Enhance energy saving awareness by visualizing electricity usage.

- Drive company-wide efforts for energy-saving improvement by sharing information on improvement cases (creating a database)

Future challenges

Our challenges to be addressed include accurately managing the data on air emission volumes at overseas sales bases, etc. in a global scale, and working to reduce the amount of "emission into the atmosphere" in collaboration with the supply chain.