Risk Management System

In order to strengthen our defense system against various risks in our operating environment, we have established a Risk Management Committee headed by the executive supervising CSR to manage risks in a cross-sectional manner and handle properly anything that may have a significant impact on the management of our company. Furthermore, in response to the specific individual risks involving compliance, safety, disasters, information security, and export management, we have established committees and councils including the Corporate Compliance Committee, Central Safety and Health Committee, Central Disaster Prevention Council, CSR Council, Environment Council, Information Security Committee, Personal Information Protection Management Committee, and Export Control Committee. We have prepared and developed regulations, guidelines, and manuals for implementing risk management, and we also conduct education and training activities.

The status of the activities of each of these committees and councils are reported to the Management Meeting as appropriate and reported to the Board of Directors when deemed necessary.

The following meetings were held in FY2017:

| 1. Risk Management Committee | Met three times |

| 2. Personal Information Protection Management Committee | Met twice |

| 3. Export Control Committee | Met twice |

| 4. Information Security Committee | Met twice |

While reports were made to the Board of Directors for issues requiring advanced management decisions, there were no risk issues reported to the Board of Directors in fiscal 2017.

Going forward, we will not neglect our daily activities, and we will implement the PDCA cycle by identifying possible risks, considering countermeasures, notifying the parties involved, and conducting verification.

Review of FY 2017 Activities

Verifying employee safety

A system for verifying employee safety was adopted in 2009, and has been implemented continuously since then.

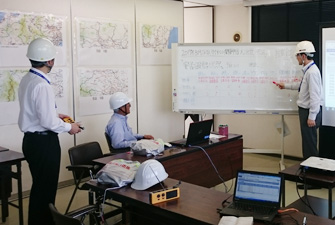

The O.E. Tire Sales & Marketing Division, which is responsible for sales of tires to automotive manufacturers for fitting to new vehicles, implements safety verification training for relevant personnel several times a year.

Yokohama Tire Japan Co., Ltd. , which sells vehicle tires and related products, also carries out safety verification training for its employees based on a disaster scenario.

Training in progress at the Sales and Marketing Division office in Kanto-Koshin region.

Being prepared for a disaster (database activation)

In FY2017, data regarding the current implementation status of the stockpiling of emergency supplies at individual business sites, evacuation training to ensure readiness in the event of a disaster occurring, and first-aid training using automated external defibrillator (AED) equipment, etc., was collated in the form of a unified database.

This has facilitated the restocking of emergency supplies of which there was a shortage, and made it possible to add new items where needed.

We have also been able to verify the content and frequency of emergency evacuation drills, and the number of people participating, to ensure that personnel can respond promptly in the event of a disaster.

In FY2017, besides re-confirming that business sites have several days’ worth of water, food etc. stockpiled, we also began preparations to enable us to act as an emergency evacuation location for local residents in the event of a disaster.