News Release

Yokohama Rubber Announces New Management Plan: Grand Design 100

Sets aim at net sales of 1 trillion yen, operating income of 100 billion yen, and operating return on sales of 10% by the year to March 31, 2018

2006.May.11

- Management relation

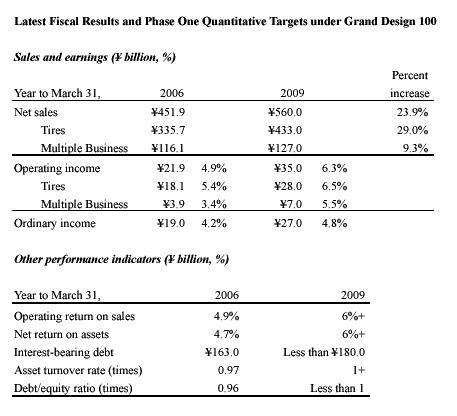

Tokyo-The Yokohama Rubber Co., Ltd., announced today that it has drafted a management plan for the 12 fiscal years to March 31, 2018. Yokohama's centenary is in 2017, and the company has dubbed its new management plan Grand Design 100. The plan comprises four three-year segments. Phase One, the first segment, spans from the present fiscal year, which began on April 1, to the year ending March 31, 2009. It follows the management plan, Grand Design 10, for the three years ended this March.

Grand Design 100 calls for achieving net sales of 1 trillion yen, operating income of 100 billion yen, and operating return on sales of 10% by the year to March 2018. The chief quantitative targets in Phase One are to increase net sales 24% over the latest fiscal year, to 560 billion yen by 2009, and to increase operating income 60%, to 35 billion yen by that year.

Yokohama has articulated a corporate vision in Grand Design 100 that emphasizes evoking a distinctive identity in building corporate value and in building a strong market presence. Its basic policy for fulfilling that vision centers on delivering the best products at competitive prices and on time, on asserting world-class strengths in technologies for protecting the environment, and on fostering a customer-oriented corporate culture that honors rigorous standards of corporate ethics.

Strategy in Yokohama's tire business under Grand Design 100 will stress profitable growth. The company has cited three themes in that strategy: products, technology, and manufacturing. Product strategy will include aggressive promotion of Yokohama's ADVAN line of high-performance tires and other high-value-added products. Technology strategy will include adopting new materials in products, integrating product specifications globally, and developing new production processes. Manufacturing strategy will include expanding production capacity in Asian nations and deploying compact production platforms. Yokohama's target for production capacity at March 31, 2009, is 56,550,000 tires a year, a 24% increase over the latest fiscal year.

In Yokohama's Multiple Business (diversified products) segment, strategy will stress asset allocation, globalization, and product development. Management has identified eight sectors of industrial products, including, hydraulic hoses and construction sealants, for allocating assets on a priority basis. Sporting goods, mainly golf products, will also remain a strategic priority. Globalization mainly will mean shifting production for a growing range of items to China. Product development will include efforts to secure footholds in new market sectors, such as electrical, electronic, and optical products and alternative energies.

Yokohama's technology strategy provides for extending core strengths, including chemical synthesis and modification and rubber and polymer compounding. The company will work on developing new materials, including natural materials, nanomaterials, modified polymers, and electrically conductive polymers, and new technologies, including nanotechnological control and ultraprecise machining. New materials and technologies that emerge from those efforts will fortify Yokohama's tires and diversified products and will present opportunities for new products in information technology, electronic materials, and other sectors.

Asserting world-class strengths in technologies for protecting the environment will include adopting consistent environmental management at all operations worldwide, minimizing the environmental impact of all products, and striving to recycle all industrial waste as raw material or as fuel. Wide-ranging environmental-protection activities will also include developing showcase tire products that exemplify environmental virtues, eliminating landfill waste and installing cogeneration systems at factories, reducing paper usage companywide through waste-reduction measures, and working in every way to reduce output of carbon dioxide.