YOKOHAMA Fixed Fenders

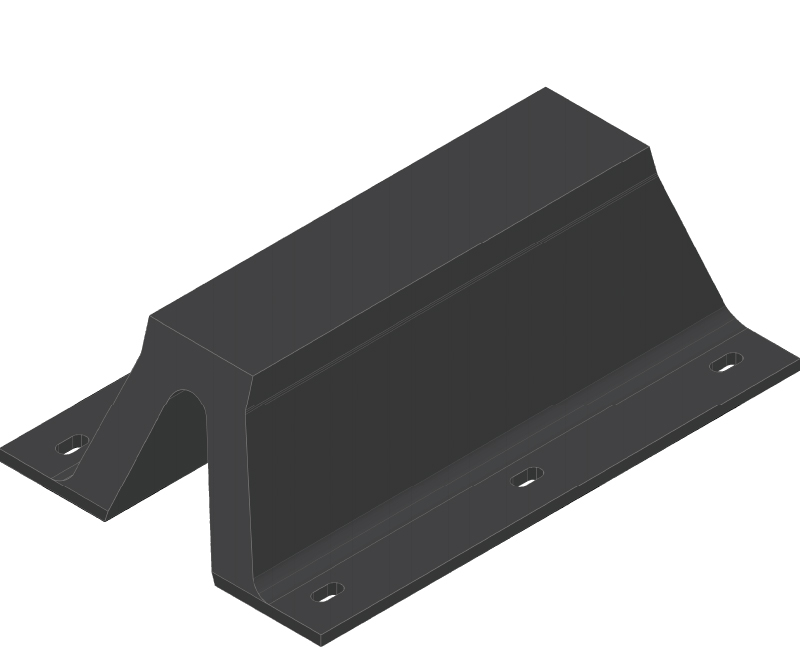

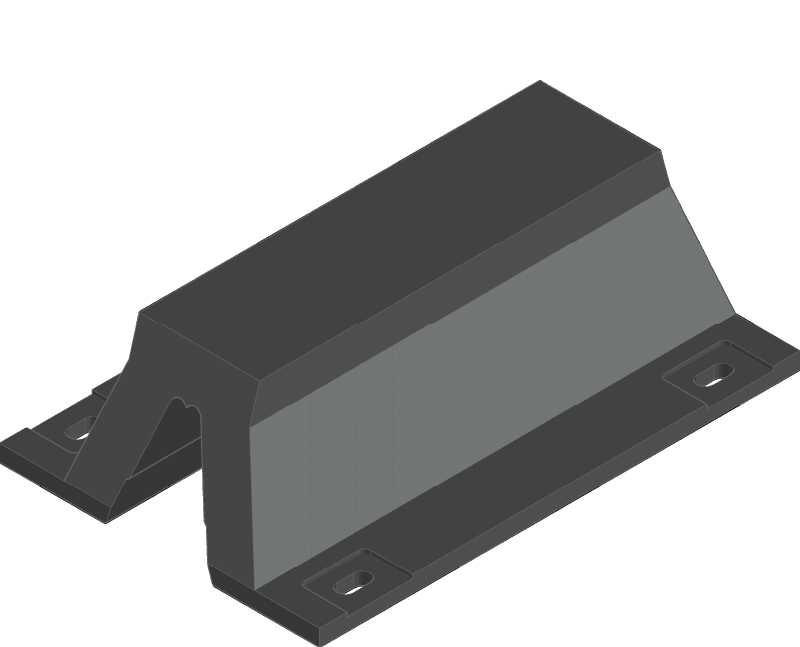

ABF-P

Air Block Fenders(ABF) are a type of pneumatic fender that Yokohama Rubber has well over forty years of experience and that are now in widespread use around the world. They were developed in order to extend the range of usage of pneumatic fenders and enable them to be used for docks, and already a large number of them are in use not only in ports in Japan but throughout the world. The ABF-P that is introduced in this brochure is an ABF that has a protector panel fitted on its front side instead of the usual ABF cap, in order to extend the range of uses of the ABF. Through this modification, it is now possible to design and manufacture a full range of sizes in accordance with the sizes of the vessels and the state of the docks. Two types are available: the ABF-P1 which is for oil tanker, LNG and LPG tankers which call for low surface pressure on their hulls,ore carriers, car ferries and other general purposes, and for places where there is a high tide range; and the ABF-P2 which is fitted with a simplified protector panel and is for berths where vessels of all sizes come alongside.

Features

Soft initial contact and gradual increase of reaction force.

Low friction force at the initial contact

No decrease of energy absorption during inclined berthing.

High resistance to shearing forces proven under test and actual conditions and shearing chains are not required.

Lower reaction forces during rough weather mooring.

Substantial safety allowance to allow for excess accidental loads.

Due to utilization of air elasticity, performance does not deteriorate due to fatigue, and the normal aging and stiffening effect of rubber do not make any influence.

Side walls are similar to a tyre structure, using reinforcing cord and various rubber layers for strength and durability. This is a major difference to solid rubber fenders where cord cannot be used as it interferes with the buckling effect.

ABF-P -Construction with protector panel

Size and Performance Table

3-2 1/1TYPE(H/D=1/1)

* Click the size to see the performance curve

| Nominal size (Height x Dia) * Click to |

Deflec- tion |

Energy Absorption (E) and Reaction Force (R) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| (1) Po=0.8 kgf /cm2 (11.4 lbs/in2) |

(2) Po=1.0 kgf/cm2 (14.2 lbs/in2) |

(3) Po=1.2 kgf/cm2 (17.1 lbs/in2) |

(4) Po=1.4 kgf/cm2 (19.9 lbs/in2) |

||||||

| Milimeters (Feet-Inches) |

% | E tf-m (ft-kips) |

R tf (kips) |

E tf-m (ft-kips) |

R tf (kips) |

E tf-m (ft-kips) |

R tf (kips) |

E tf-m (ft-kips) |

R tf (kips) |

| 600HX600φ (2' x2') |

65 | 2.2 (15.9) |

15.0 (33.1) |

2.6 (18.8) |

16.9 (37.3) |

2.9 (21.0) |

19.1 (42.1) |

3.3 (23.9) |

2.18 (48.1) |

| 800x800 (2'-7''x2'-7") |

65 | 5.3 (38.3) |

26.7 (58.9) |

6.1 (44.1) |

30.0 (66.2) |

6.9 (49.9) |

34.0 (75.0) |

7.8 (56.4) |

38.8 (85.6) |

| 1000x1000 (3'-4"x3'-4") |

65 | 10.3 (74.5) |

41.7 (91.9) |

11.9 (86.1) |

46.9 (103) |

13.5 (98.4) |

53.1 (117) |

15.2 (110) |

60.6 (134) |

| 1070x1070 (3'-6"x3'-6") |

65 | 12.7 (91.9) |

47.7 (105) |

14.6 (106) |

53.7 (118) |

16.6 (120) |

60.8 (134) |

18.6 (135) |

69.4 (153) |

| 1200x1200 (4'x4') |

65 | 17.9 (129) |

60.0 (132) |

20.6 (132) |

67.5 (149) |

23.4 (169) |

76.5 (169) |

26.3 (190) |

87.3 (192) |

| 1330x1330 (4'-4"x4'-4") |

65 | 24.3 (176) |

73.7 (163) |

28.0 (203) |

82.9 (183) |

31.9 (231) |

94.0 (207) |

35.8 (259) |

107 (236) |

| 1470x1470 (5'x5') |

65 | 32.9 (238) |

90.0 (198) |

37.9 (274) |

101 (223) |

43.0 (311) |

115 (254) |

48.3 (349) |

131 (289) |

| 1600x1600 (5'-3"x5'-3") |

65 | 42.4 (307) |

107 (236) |

48.8 (353) |

120 (265) |

55.5 (401) |

136 (300) |

62.3 (451) |

155 (342) |

| 1800x1800 (6" x6') |

65 | 60.3 (436) |

135 (298) |

69.5 (503) |

152 (335) |

79.0 (571) |

172 (379) |

88.8 (642) |

196 (432) |

| 2000x2000 (7'x7') |

65 | 82.8 (599) |

167 (368) |

95.4 (690) |

187 (412) |

108 (781) |

212 (467) |

122 (882) |

242 (534) |

| 2400x2400 (8'x8') |

65 | 143 (1034) |

240 (529) |

165 (1193) |

270 (595) |

187 (1353) |

306 (675) |

210 (1519) |

349 (770) |

| 2670x2670 (9'x9') |

65 | 197 (1425) |

297 (721) |

227 (1642) |

334 (736) |

258 (1866) |

379 (836) |

290 (2098) |

432 (953) |

| 2800x2800 (9'-3"x9'-3") |

65 | 227 (1642) |

327 (721) |

262 (1895) |

367 (809) |

297 (2148) |

416 (917) |

334 (2416) |

475 (1047) |

| 3000x3000 (10'x10') |

65 | 279 (2018) |

375 (827) |

322 (2329) |

422 (931) |

366 (2647) |

478 (1054) |

411 (2973) |

546 (1204) |

| 3200x3200 (10'-6" x10'-6") |

65 | 339 (2452) |

427 (942) |

391 (2828) |

480 (1058) |

444 (3211) |

544 (1200) |

499 (3609) |

621 (1369) |

NOTES:

Reaction force and energy absorption are measured under static condition.

Tolerances of reaction force and deflection at guaranteed energy absorption are as follows: ●Reaction force:±10% ●Deflection:±5%

Figures of nominal sizes in feet and inches are rounded off, do not use for dimensional purposes.

Po:Initial inner pressure

V Type Fenders

YOKOHAMA YAV/YYA series Arch Fenders are available for a wide range of applications. They have been certified by the Specialists Center of Port and Airport Engineering (SCOPE).

Features

Good energy/reaction force ratio

Can be installed vertically, horizontally and crossly

Various dimension range to suit the requirement

Excellent weather, ozone and seawater resistance

Type YAV

Type YYA

Cell Fenders, Cone Fenders

YOKOHAMA Rubber Fender Series Cone Fenders/Cell Fenders can achieve a higher level of energy absorption upon impact. They can be used on quays accepting a wide range of vessels, from small ships to large passenger ships, cargo ships, and tankers. They have been certified by the Specialists Center of Port and Airport Engineering (SCOPE).

Features

Excellent energy/reaction force ratio

Good robustness and shear resistance

Absorb impact from all directions evenly due to its cylindrical/conical shape

Optimize its performance characteristics with shock absorbing plates in combination

Cell Type Fender

Cone Type Fender