Next-generation environment-friendly automotive air-conditioning hose

Yokohama Rubber is now developing a next-generation environment-friendly automotive air-conditioning hose using a rubber-resin polymer alloy. This alloy has a sea-island structure that realizes high gas barrier properties while maintaining the flexibility and heat resistance of rubber. As a result, we succeeded in making the hose thinner and achieved a significant weight reduction of 50% compared to conventional hoses.

Yokohama Rubber’s wide variety of structural designs for hoses, advanced assembly technologies, and product evaluation techniques enables us to provide hose products that meet diverse customer needs.

We welcome all inquiries from OEMs, Tier-1 suppliers, resin component suppliers, and raw material suppliers, and others interested in our new technology. Please click the below link to send an inquiry. One of our dedicated company engineers will respond as quickly as possible.

Please direct inquires to here

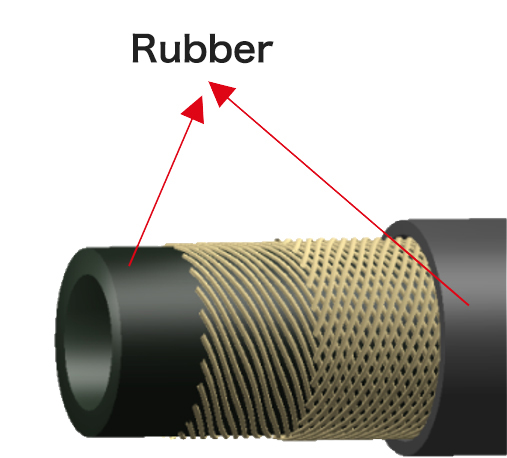

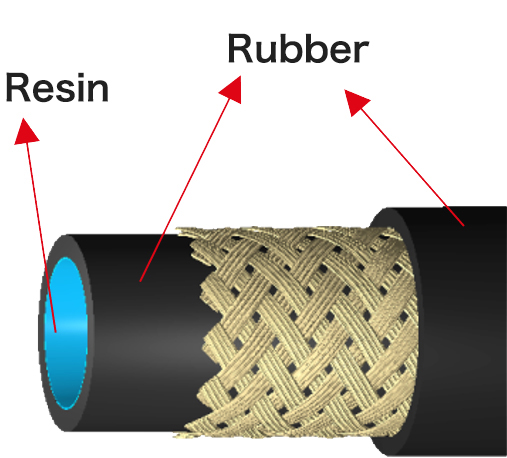

Conventional air-conditioning hoses

All-rubber type

Internal resin-layer type

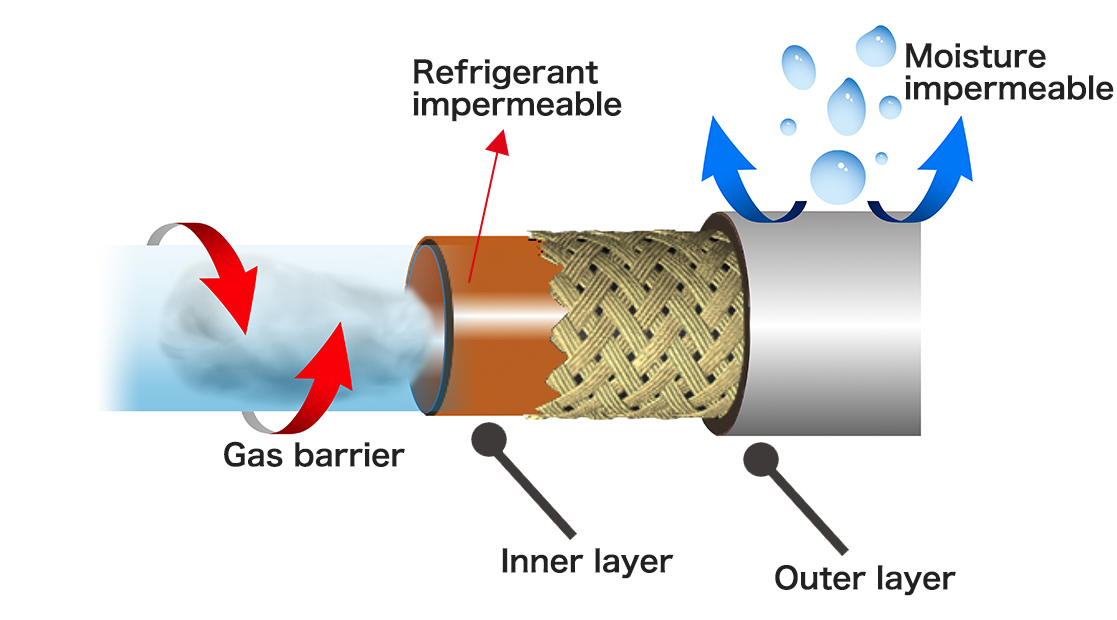

Next generation air-conditioning hose

| Inner layer | Outer layer |

|---|---|

| Flexible | |

| Heat resistant | |

| Oil resistant | |

| Gas barrier properties | Moisture impermeable |

Rubber-resin polymer alloy development

"Yokohama Rubber proprietary material"

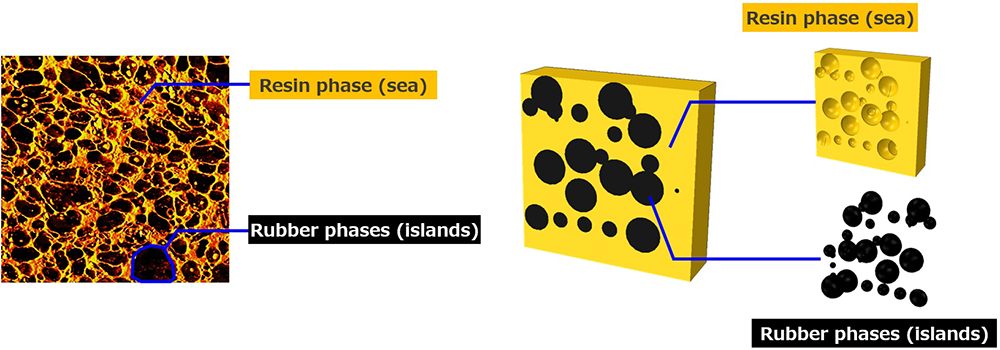

Structure of new rubber-resin polymer alloy

Using our proprietary material technology, we created a structure with an optimal arrangement of rubber and resin. Yokohama Rubber’s new rubber-resin polymer alloy has a sea-island structure in which the rubber island phase is dispersed in the resin sea phase.

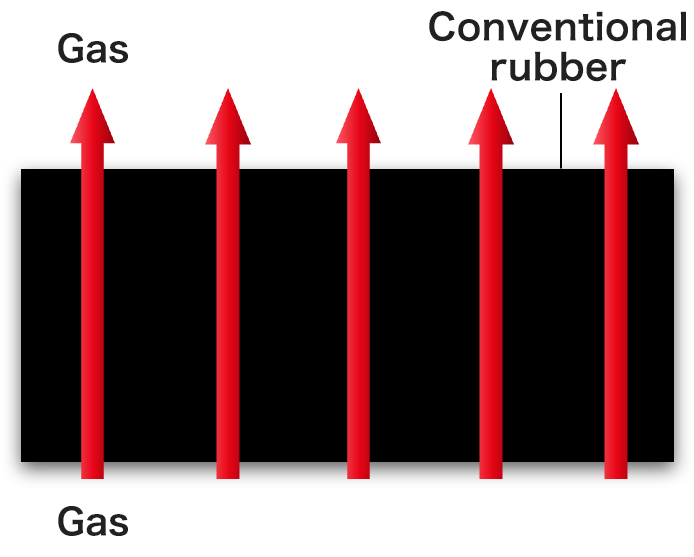

Conventional rubber

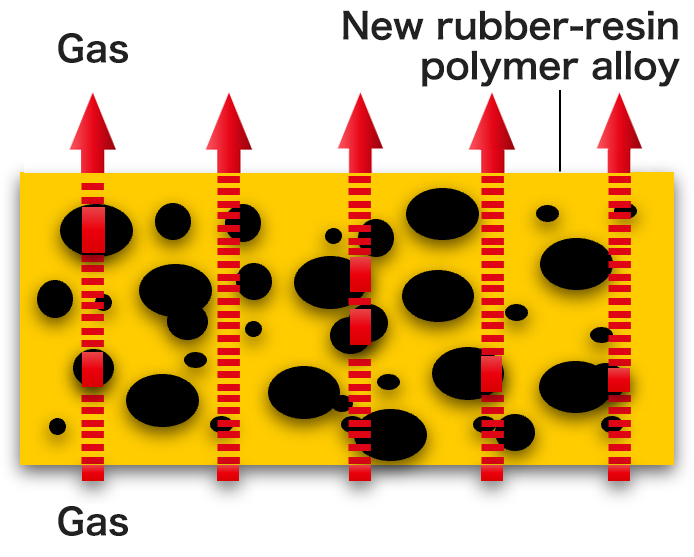

New rubber-resin polymer alloy

The new rubber-resin polymer alloy’s resin phase suppresses the gas penetration rate making it difficult for gas to escape

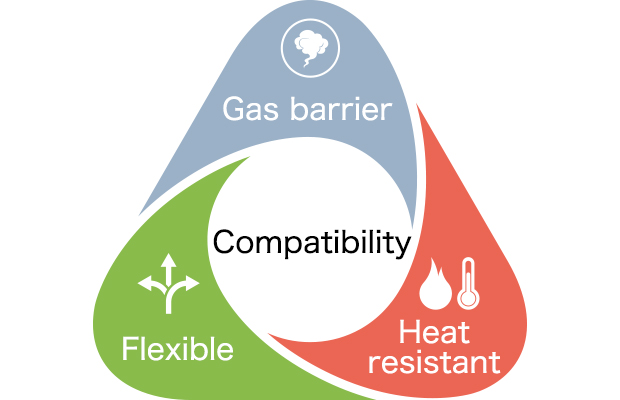

By making our new rubber-resin polymer alloy a sea-island structure, it provides high gas barrier properties while maintaining the flexibility and heat resistance of rubber. Conventional rubber is generally made thicker to ensure gas barrier properties, but this increases the weight of the hose. The high gas barrier performance of the newly developed polymer alloy’s resin phase allows us to reduce the thickness and reduce the weight of the hose.

Challenge to develop resin piping

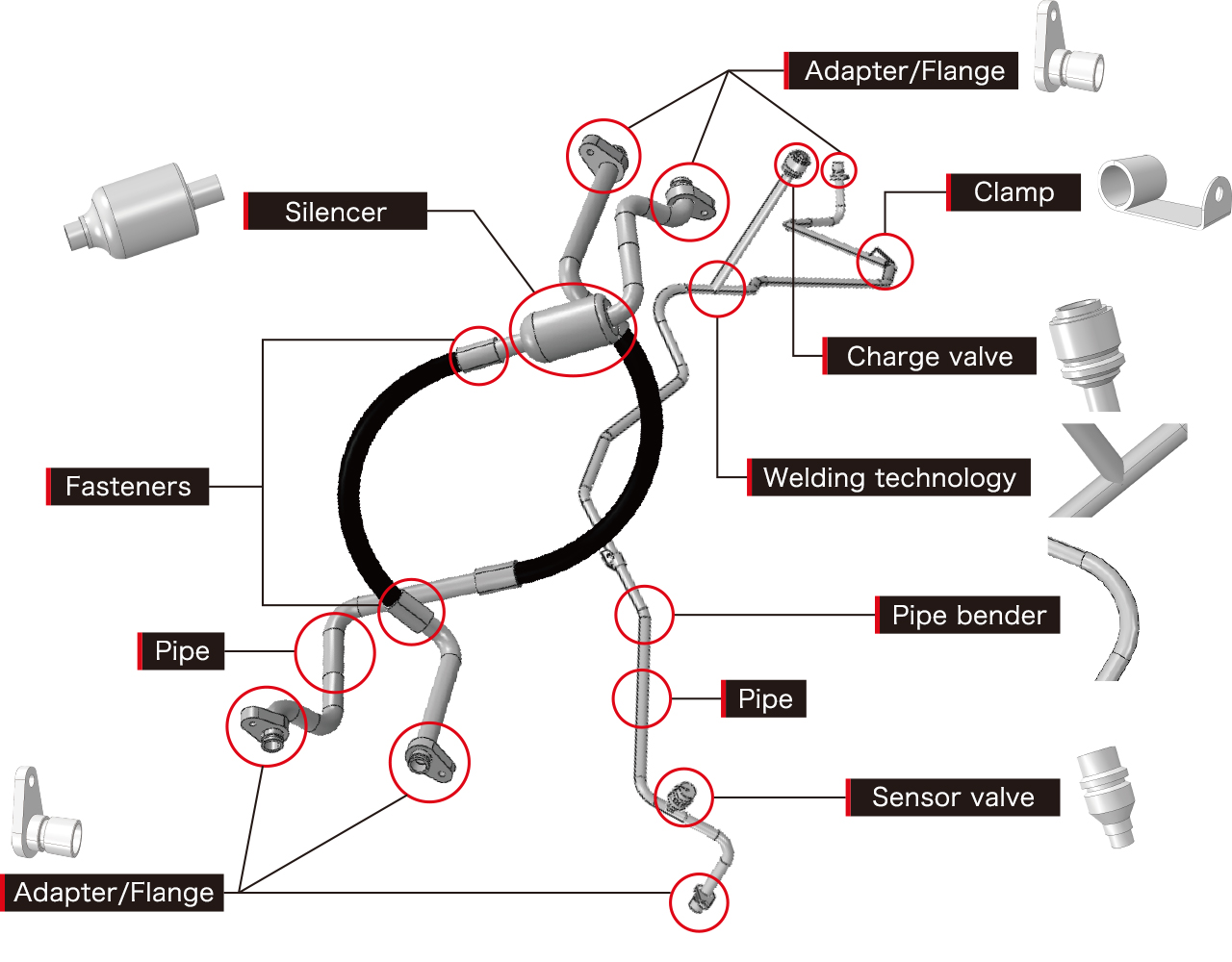

Aiming to use resin in almost all parts of the pipe system

Applying diverse technologies to achieve pipe resinization

Seeking partners for joint development effort

AC Pipe System

We provide innovative solutions

Yokohama Rubber’s wide variety of structural designs for hoses, advanced assembly technologies, and product evaluation enables us to meet diverse customer needs.

Future initiatives

We believe that this new high polymer material can be applied to other applications such as battery cooling lines, as well as to other areas, such as hydraulic equipment and aerospace products.

We are also considering applying this new technology to other routing improvements.