News Release

YOKOHAMA Develops New Inner Liner Technology for Commercial Vehicle Tires

Substantially Reduces Natural Air Leakage

2013.April.16

- Tire relation

- Technical relation

Tokyo - The Yokohama Rubber Co., Ltd., announced today that it has developed new inner liner technology that substantially improves the ability to maintain air pressure in commercial vehicle tires for trucks and buses. The new inner liner can reduce natural air leakage by about 30%* compared with conventional liners, helping maintain tire pressure and allowing the design and manufacturing of lighter tires. The new inner liner technology is being applied to tires manufactured at domestic plants from April 2013, and will gradually be introduced at plants overseas.

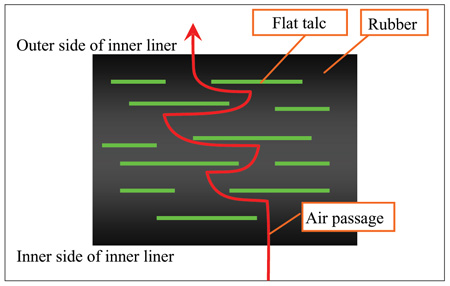

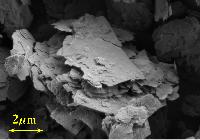

Inner liners are rubber sheets covering the interior surfaces of tubeless tires to reduce air leakage from the tire. YOKOHAMA's new inner liner uses "flat talc" - particulate talc in planar shapes, a key characteristic of the mineral talc - imbedded in the rubber in multiple layers. The flat talc blocks the permeation of air through the rubber, substantially cutting the volume of air naturally escaping from the tire.

Under-inflation of a tire not only reduces fuel efficiency due to increased rolling resistance, but adversely affects wear and safety. For those reasons, YOKOHAMA has been engaged in research and development of inner liner technology to reduce air leakage. In 2009, it released its "AIRTEX Advanced Liner," created from new materials, for passenger cars, and has employed in fuel-efficient tires and comfort tires.

*Detailed test results are on file with the Tire Fair Trade Council in Japan.

How new inner liner reduces air permeation