What is Sustainable Natural Rubber?

What kind of resource is natural rubber?

When you hear the word "rubber", what kind of image do you have in your mind?

Perhaps you think of something soft, stretchy, bouncy, or something that keeps things from slipping or reduces noise or vibration. It may bring to your mind many things, and all of them are valid properties of rubber.

There are two types of rubber material, that are natural rubber and synthetic rubber. Natural rubber is made from plants such as Hevea brasiliensis (para rubber trees), while synthetic rubber is made from petroleum and other additives. Natural rubber has only been used commercially during the last 200 years of human history. However, it is believed that natural rubber will play an increasingly important role in our increasingly circulating society.

Para rubber trees that produce natural rubber

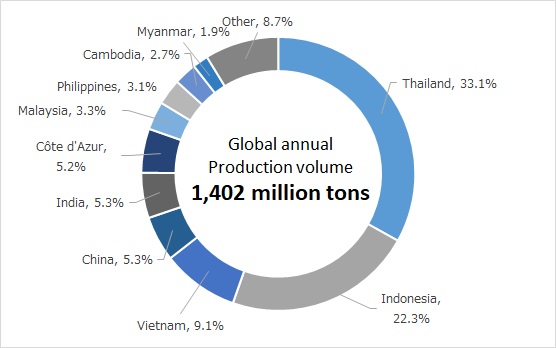

Presently, most natural rubber used commercially is made by collecting the tree sap, or latex, from cuts made in the bark of para rubber trees (Hevea braziliensis) and coagulating rubber components contained in the latex. The main natural rubber production regions of the word are located in hot and humid tropical areas in Southeast Asia, Africa and Latin America. Among these regions, Southeast Asia accounts for about 80% of the world natural rubber production.

Main uses of natural rubber

Natural rubber is used in car tires, rubber bands, hoses, conveyor belts and various mechanical components While rubber is used for a great variety of purposes from something close to our everyday life to ones rarely seen, approximately 70% of global natural rubber production is used for making vehicle tires. Due to its high strength, natural rubber is often used in large-size vehicle tires, especially those for trucks, buses and industrial vehicles.

About 20% of the raw materials purchased by Yokohama Rubber are natural rubber

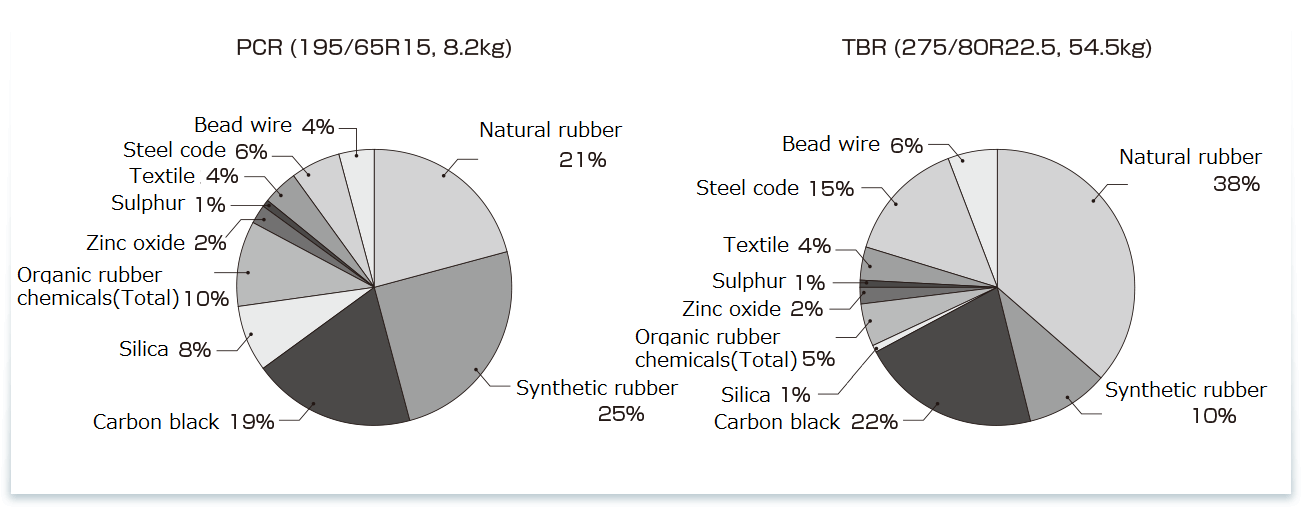

Yokohama Rubber makes a variety of rubber products including car tires. You probably think of car tires as a black, round mass of rubber, but many other materials and components are required, including metal, fiber, carbon black and oil, to make car tires. Natural rubber is an important raw material that accounts for about 20% of the raw materials purchased by Yokohama Rubber.

There are various kinds of tires such as ones for passenger cars, trucks and buses, for vehicles carrying heavy loads or ones that are used in harsh conditions, and ones for agricultural vehicles. Large tires that require higher durability contains a greater percentage of natural rubber in their material.

It is essential for Yokohama Rubber to ensure a sustainable and reliable supply of natural rubber in order to continue the stable supply of products to our customers.

Natural rubber is an excellent resource in many aspects

Para rubber trees absorb carbon dioxide in the air and make natural rubber that is used as a raw material for industrial products. In addition, para rubber trees are carbon-positive (having CO2 absorption and fixation effects) plants because they store carbon in their body. Natural rubber production also brings employment and income to the producing regions, forming a robust industry that supports local economies.

Trees that can no longer produce latex are cut down and used for making furniture.

In order to stably produce natural rubber of the same quality, para rubber trees grown in natural rubber farms are normally genetic clones having the same genes. Saplings are usually made by planting and growing cuttings taken from the trees of the same family. After the saplings are planted, it takes five to six years for their trunks to grow thick enough to produce natural rubber. Para rubber trees keep actively produce latex for about 20 to 25 years after being planted and then their production gradually declines, making regular replanting necessary. Aged para rubber trees are cut down and are widely used for producing furniture and wooden floors. There is nothing to be wasted in rubber trees.

Social risks related to natural rubber production

The global demand for natural rubber has nearly tripled over the last 40 years. This is due largely to the global population growth and to the rapid spread of motorization. Parallel to such growing demand and production of natural rubber, there are concerns about problems such as illegal deforestation, land deprivation and human rights violations, as well as negative impacts on biodiversity caused by deforestation and illegal logging in an effort to provide more land to plant natural rubber trees.

Natural rubber farms increasing in tropical rainy areas

Among the regions that produce natural rubber, Southeast Asia accounts for about 80% of the world's supply. It is also a region that contains vast spreads of tropical rain forests. Tropical rain forests are abundant in biodiversity and are home to many rare living creatures. The expansion of natural rubber and other plantations in such area can affect the lives of those precious creatures. In some regions, illegal plantation development in natural parks and other protected areas are suspected or threatened.

Instead of just increasing the area of farmland to meet the increasing demand for natural rubber, we must do more to increase the sustainability of natural rubber production, for example by increasing the volume of rubber harvested per area or extending the harvest season so as to increase the production without diminishing the area of tropical rain forests, and also to reduce the amount of natural rubber used in tire production by making the tires lighter and smaller.

Natural rubber can be grown in geographical areas across 15 degrees to the north and south of the equator, which overlap the areas of tropical rain forests (green).

Major natural rubber-producing countries

Social issues related to human rights violation and poverty

Most natural rubber is not produced by large scale plantations. Natural rubber trees are mainly grown by small farms called "small holdings". It is estimated that there are six million such "small holders" that grow natural rubber trees on small scales in various areas around Southeast Asia. These are concerns about various problems connected to natural rubber production on such small farms, such as poverty, lack of productivity due to insufficient knowledge, know-how and experience in rubber farming and harvesting, and greater detrimental impact on nature due to lack of environmental consideration.

Difficulty and importance of traceability

The price of natural rubber fluctuates in the international market. Dealers who purchase raw rubber from natural rubber farmers check the market price every day to decide whom they sell the rubber to or whether they sell it immediately or store it in the warehouse for later sales. While raw latex freshly collected from para rubber trees is extremely perishable, it can be coagulated into cup lumps or USS (unsmoked sheets), that can be stored for much longer. These coagulated forms of rubber are often traded between dealers or across multiple countries and regions. For this reason, it can be very difficult to identify by what commercial channel a given supply of natural rubber has reached the final rubber processing factory from the producer to establish traceability. At the same time, we are under greater social pressure to prove that any batch of natural rubber we purchase has not come from a source that engages in deforestation or human rights violation.

Initiatives to make natural rubber a sustainable resource

As a socially responsible tire manufacturer operating on global scale, Yokohama Rubber has various ongoing initiatives to make natural rubber a truly sustainable resource. Through these initiatives, we aim at exactly identifying in what farm each of our purchased natural rubber batches was produced (establishment of traceability), and building a framework that will enable sustainable production of natural rubber in the future by addressing the problems faced by the farms and the people living in the regions, with the aim of establishing true sustainability of natural rubber production in those regions. We also intend to actively contribute to the SDG goals through these activities.

Contributions to the SDG goals through our natural rubber sustainability initiatives

Move the screen to the left or right to see the table information

| SDGs Goal | Goals and Targets |

|---|---|

|

1.End poverty in all its forms everywhere. |

|

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities. |

|

10.2 By 2030, empower and promote the social, economic and political inclusion of all, irrespective of age, sex, disability, race, ethnicity, origin, religion or economic or other status. |

|

12.2 By 2030, achieve the sustainable management and efficient use of natural resources. |

| 12.a Support developing countries to strengthen their scientific and technological capacity to move towards more sustainable patterns of consumption and production. | |

|

15.2 By 2020, promote the implementation of sustainable management of all types of forests, halt deforestation, restore degraded forests and substantially increase afforestation and reforestation globally. |

|

16.2 End abuse, exploitation, trafficking and all forms of violence against and torture of children. |

|

17.17 Encourage and promote effective public, public-private and civil society partnerships, building on the experience and resourcing strategies of partnerships. |

Signing and participating in international initiatives

In 2017, Yokohama Rubber announced its support and participation to the Sustainable Natural Rubber Initiative (SNR-i), a framework advocated by the International Rubber Study Group (IRSG). Yokohama Rubber is also a founding member of the Global Platform for Sustainable Natural Rubber (GPSNR), a program sponsored by the Tire Industry Project (TIP) of the World Business Council for Sustainable Development (WBCSD).

Revision of our sustainable natural rubber procurement policy

Yokohama Rubber revised its Sustainable Natural Rubber Procurement Policy, originality formulated in October 2018, in September 2021. The 2021 revision was intended to align our procurement policy with the new framework adopted by GPSNR at its second general assembly held in September 2020. The revision also serves as a statement of Yokohama Rubber's mission to pursue a greater level of natural rubber sustainability.

Overview of the Procurement Policy for Sustainable Natural Rubber

- Enhancing traceability

- Respect for human rights and prohibit any form of harassment

- Fair and equitable treatment

- Prohibition of child labor and forced labor

- Compliance

- Initiatives for zero deforestation

- Consideration for biodiversity

- Abiding by the principle of free, prior and informed consent (FPIC) in regard to land rights

- Creation of innovative technologies

- Communication with suppliers

Networking with our natural rubber suppliers

Yokohama Rubber has held a series of networking events (Suppliers' Day) with its natural rubber suppliers since 2016. At the networking event in April 2018, which was held by inviting to Japan a total of 42 representatives from 25 companies across five countries, we urged the suppliers to have a shared understanding and support for our effort to make natural rubber a sustainable resource in accordance with Yokohama Rubber's CSR policy.

While we were unable to hold the event in 2020 due to the COVID-19 pandemic, we had an online networking event jointly hosted with our group company based in Singapore, Yokohama Rubber Singapore Pte. Ltd. in May 2022.

At this event, we explained the environmental aspects of our ESG mid-term plan and our human rights policy formulated in April 2022, and asked for cooperation in our efforts based on our sustainable natural rubber procurement policy for closer partnership and shared understanding with our suppliers. In the event, our president appreciated the suppliers for providing us with natural rubber of consistently good quality, and presented trophies to suppliers who had made outstanding contributions to our business. We also received a video message from Mr. Stefano Savi, Director of GPSNR, congratulating us on the success of the event.

Suppliers Day