Governance

Sustainability Management

Sustainability Management Promotion Framework

Important Issues of the Yokohama Rubber Group

Environmental Management System

Enforcement of Environmental Training and Education

Environmental Accounting

Sustainability Management Promotion Framework

Twice a year (in May and November), we hold a CSR Council where our President serves as a chairperson, as part of an organizational framework that was set up to discuss and develop plans for addressing the social responsibility issues that Yokohama Rubber Group is currently facing.

Organizations including the CSR Council, the Corporate Compliance Committee, the Environment Council, the Central Labor Relations Committee, the Central Safety and Health Committee, and the Risk Management Committee have been established, with the responsible officers serving as chairpersons to deliberate on various issues.

Matters with a material impact on management are submitted to the Management Meeting for approval.

We have three task forces, two sub-councils, and four committees that promote environmental activities as sub-bodies within the Environmental Council. The Environmental Council engages in business activities as a product development framework and continues to provide environmentally friendly products.

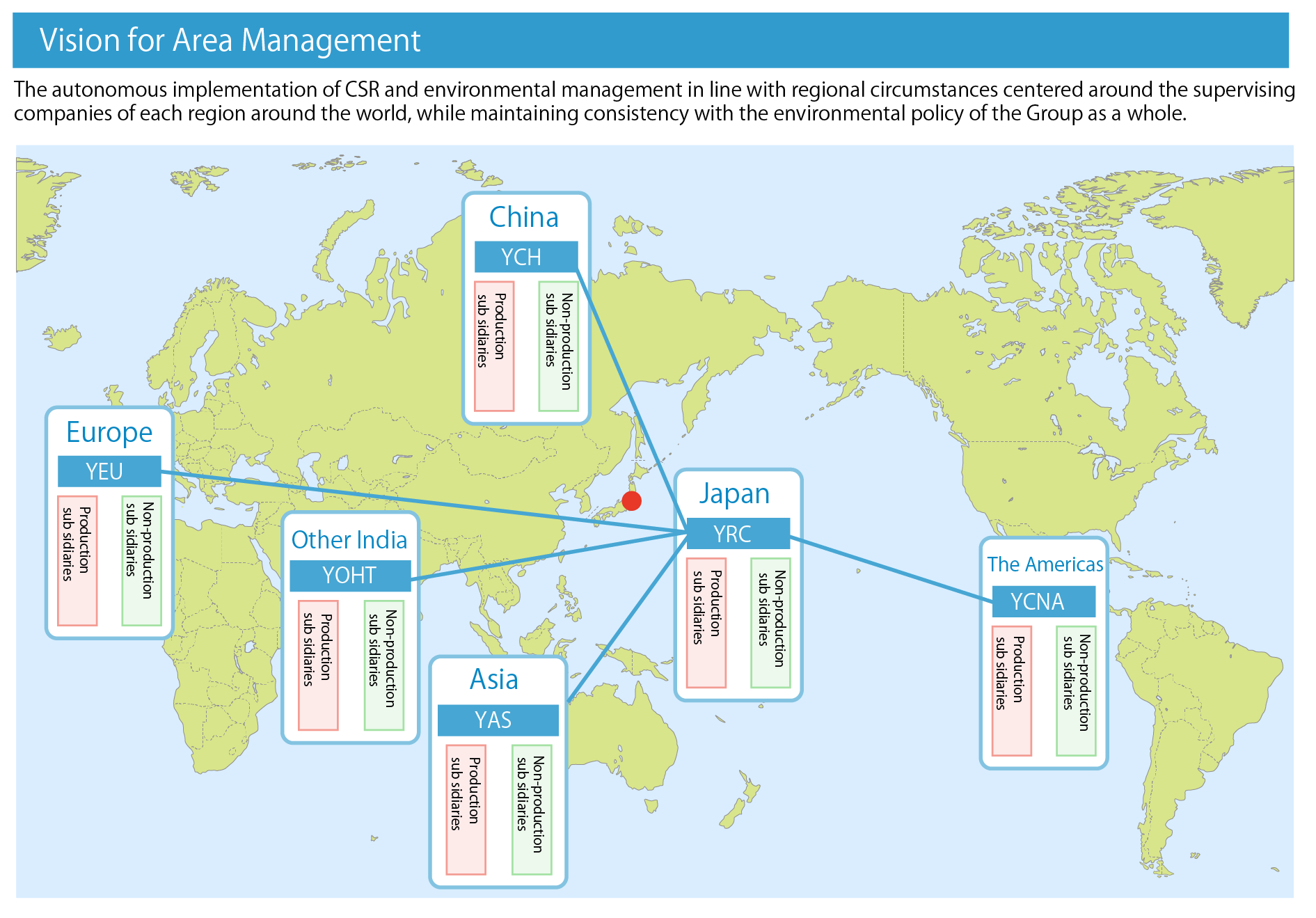

In addition, with the aim of implementing high quality and homogeneous sustainability management at all of our bases around the world, we are promoting area management of internal controls, including the environment and compliance, under the control of the regional management company. In fiscal 2022, an environmental conference was held in the China area, and education on the introduction of a complaint handling system was conducted in Thailand and other countries.

Organizations including the CSR Council, the Corporate Compliance Committee, the Environment Council, the Central Labor Relations Committee, the Central Safety and Health Committee, and the Risk Management Committee have been established, with the responsible officers serving as chairpersons to deliberate on various issues.

Matters with a material impact on management are submitted to the Management Meeting for approval.

We have three task forces, two sub-councils, and four committees that promote environmental activities as sub-bodies within the Environmental Council. The Environmental Council engages in business activities as a product development framework and continues to provide environmentally friendly products.

In addition, with the aim of implementing high quality and homogeneous sustainability management at all of our bases around the world, we are promoting area management of internal controls, including the environment and compliance, under the control of the regional management company. In fiscal 2022, an environmental conference was held in the China area, and education on the introduction of a complaint handling system was conducted in Thailand and other countries.

Important Issues of

the Yokohama Rubber Group

In order to build a trusted identity as a contributing member of the global community, Yokohama Rubber Group acts in accordance with the Yokohama Rubber Group Action Guidelines together with its stakeholders, which include customers, shareholders and investors, business partners and suppliers, and employees.

To this end, the Yokohama Rubber Group has specified the following critical issues in reference to benchmarks including the GRI Guidelines and ISO26000, and conducts activities in response as the Critical Issues of the Yokohama Rubber Group.

To this end, the Yokohama Rubber Group has specified the following critical issues in reference to benchmarks including the GRI Guidelines and ISO26000, and conducts activities in response as the Critical Issues of the Yokohama Rubber Group.

As a company with a trusted identity as a contributing member of the global community, the Yokohama Rubber Group creates and provides to society the following forms of value while implementing the strategy of the YX2023 medium-term management plan based on the Action Guidelines, in order to move forward together with stakeholders.

For more information about the YX2023 medium-term management plan, see the “Investor Relations” section of the Yokohama Rubber corporate website.

For more information about our CSR measures, see the section of the Yokohama Rubber corporate website that outlines our “Caring for the Future” CSR Slogan.

For more information about our CSR measures, see the section of the Yokohama Rubber corporate website that outlines our “Caring for the Future” CSR Slogan.

Environmental

Management System

Enforcement of Global Environmental Management Based on ISO14001

We aim to maintain high-quality environmental management under the same standard both in domestic and overseas group companies; thereby we have positioned ISO14001, which is the international Environmental Management System standard, as the basis of our management.

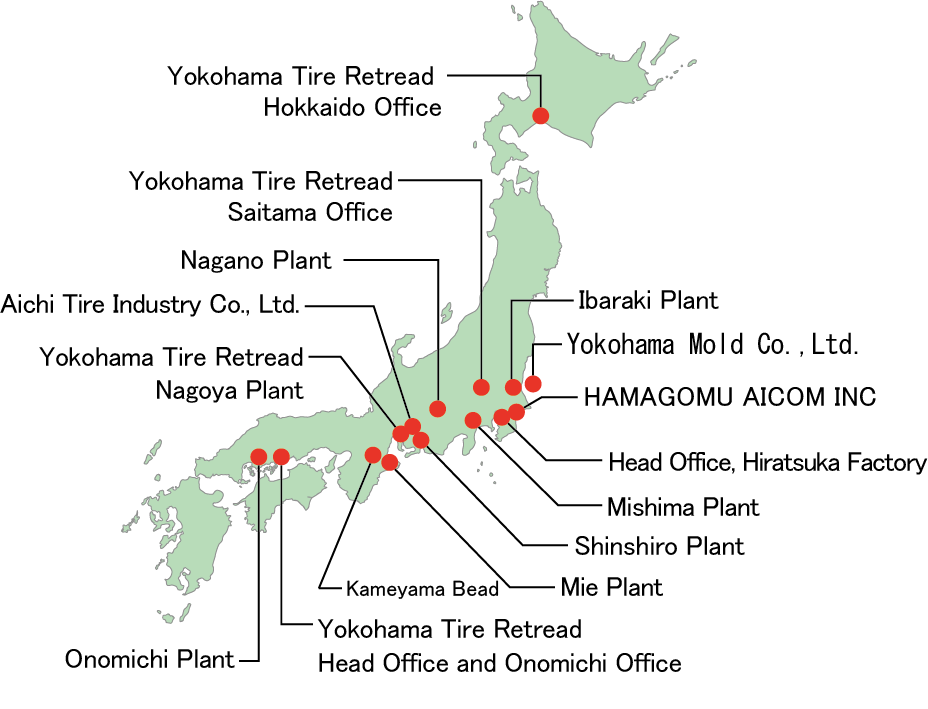

We are trying to get all our operation sites to obtain ISO14001; so far, a total of 16 operation sites in Japan, comprising eight from Yokohama Rubber and eight from our group for domestic operations have obtained it, whereas overseas a total of 30 operation sites of 16 group companies have been certified. (The ISO 14001 certification rate for production sites is 100%.)

It should be noted that during fiscal 2012, ISO14001 integrated certification was acquired for the integrated environmental management of Yokohama Rubber’s ten production bases and the head office, and a total of 16 Yokohama Rubber and Group company offices acquired ISO14001:2015 integrated certification in 2018. This reflects the high level of homogenization.

In addition, our non-manufacturing sites are promoting environment management in accordance with the ‘CSR Environmental Management Guidelines’ and our approach to the environment.

The Yokohama Rubber head office and systems company in Japan and Group distribution subsidiaries in Australia and Taiwan have acquired ISO14001 certification, under which they are further advancing their environmental management.

Our tire production facility in Thailand has also acquired ISO 50001 certification for its energy management system.

We are trying to get all our operation sites to obtain ISO14001; so far, a total of 16 operation sites in Japan, comprising eight from Yokohama Rubber and eight from our group for domestic operations have obtained it, whereas overseas a total of 30 operation sites of 16 group companies have been certified. (The ISO 14001 certification rate for production sites is 100%.)

It should be noted that during fiscal 2012, ISO14001 integrated certification was acquired for the integrated environmental management of Yokohama Rubber’s ten production bases and the head office, and a total of 16 Yokohama Rubber and Group company offices acquired ISO14001:2015 integrated certification in 2018. This reflects the high level of homogenization.

In addition, our non-manufacturing sites are promoting environment management in accordance with the ‘CSR Environmental Management Guidelines’ and our approach to the environment.

The Yokohama Rubber head office and systems company in Japan and Group distribution subsidiaries in Australia and Taiwan have acquired ISO14001 certification, under which they are further advancing their environmental management.

Our tire production facility in Thailand has also acquired ISO 50001 certification for its energy management system.

Overseas business locations that have acquired ISO14001 certification

Japanese business locations that have acquired ISO14001 certification

As of March 2023

Execution of Comprehensive Environmental Audit

We are conducting audits as to continual progression for improvement on the management system of environmental management, improvement on the environmental performance, and minimizing environmental risks per operation unit by conducting internal audits of business locations as a first-party audit, integrated internal audits by the Environmental Protection Promotion Department, and an external audit as a third-party audit every year (all audits are based on ISO14001).

Also, our Environmental Protection Promotion Department is checking and verifying the score of self-evaluation at each business site in accordance with CSR Environmental Management Guidelines for domestic distribution companies within our group.

There were no indications of any violation of environmental legislation among all the auditing items in fiscal 2022.

Also, our Environmental Protection Promotion Department is checking and verifying the score of self-evaluation at each business site in accordance with CSR Environmental Management Guidelines for domestic distribution companies within our group.

There were no indications of any violation of environmental legislation among all the auditing items in fiscal 2022.

Internal Audit

Overseas production sites have acquired and implemented ISO14001 certification.

Through our internal audit, we work to continually improve the level of our environmental management system. We conducted our audit not just to operate and maintain our environmental management system, but also by setting our common themes as whether our system is duly functioning for our purposes, whether each member of our group is walking the talk by reviewing and setting up the guidelines, purposes, and target by shifting more focus on the reduction of environmental burden in an even more proactive manner during their normal business activities.

Through our internal audit, we work to continually improve the level of our environmental management system. We conducted our audit not just to operate and maintain our environmental management system, but also by setting our common themes as whether our system is duly functioning for our purposes, whether each member of our group is walking the talk by reviewing and setting up the guidelines, purposes, and target by shifting more focus on the reduction of environmental burden in an even more proactive manner during their normal business activities.

Integrated internal audit

Integrated certification has been acquired for production sites in Japan. In order to make overall improvements to environmental management and work towards the cross deployment of key issues, internal audits are also conducted by members from each site.

In fiscal 2022, we conducted internal audits based on the positioning for fiscal 2015, and we worked to improve the level of chemical substance control and response to environmental risks, focusing in particular on our production and development sites.

Also, we focused on the promotion of various activities to contribute to society from the perspective of CSR and the level of communication with stakeholders, including local residents, in the audit.

In fiscal 2022, we conducted internal audits based on the positioning for fiscal 2015, and we worked to improve the level of chemical substance control and response to environmental risks, focusing in particular on our production and development sites.

Also, we focused on the promotion of various activities to contribute to society from the perspective of CSR and the level of communication with stakeholders, including local residents, in the audit.

External Audit

During fiscal 2022, an integrated EMS certification registration audit was continued by an ISO audit registration organization that covered all of the group’s Japanese production bases and its Headquarters, and as a result we successfully completed a periodic review ISO14001:2015.

While no nonconforming items were found in the audit, we strove to make continuous improvements.

While no nonconforming items were found in the audit, we strove to make continuous improvements.

Enforcement of

Environmental Training and Education

CSR and Environmental Training

We have incorporated CSR and environmental training as one of the subjects to be studied by recent graduate hires and mid-career hires. In addition, a career development course, "CSR and Environmental Knowledge," was held for employees in their second to third year of employment in personnel training for career-track positions.

In addition to learning about the environment in general, education on biodiversity conservation including a river monitoring experience was provided. In the first half of FY2022, the course was held on video-on-demand (monitoring experience was also provided only for viewing) due to the expansion of COVID-19 infection.

In the second half of the fiscal year, the seminar was held online and monitoring was conducted via a live broadcast from the river. A total of 78 participants took the course in the first and second semesters.

Furthermore, we held a career development course, "CSR (Intermediate Level)," for employees who have been with the company for about 10 years.

A total of 128 participants took the course, which covered knowledge on SDGs, ESG investment, and other CSR issues such as the environment, health and safety, Disaster Prevention and BCP.

These career development courses are positioned as mandatory training for promotion.

823 employees have participated in CSR training so far, or 16% of the Yokohama Rubber non-consolidated total.

In addition, in order to ensure that our managerial and supervisor level employees thoroughly understand ISO14001, we are conducting training classes for environmental internal auditors. Including 98 personnel who have completed this course to get certified in fiscal 2022, currently a total of 2,548 personnel have been registered and are already active as our internal auditors. (45% are qualified internal auditors in the scope of the integrated certification.)

We conduct skill improvement seminars to further improve the levels of employees with internal auditor qualifications. This time, due to the Corona disaster, it was not conducted.

In addition to learning about the environment in general, education on biodiversity conservation including a river monitoring experience was provided. In the first half of FY2022, the course was held on video-on-demand (monitoring experience was also provided only for viewing) due to the expansion of COVID-19 infection.

In the second half of the fiscal year, the seminar was held online and monitoring was conducted via a live broadcast from the river. A total of 78 participants took the course in the first and second semesters.

Furthermore, we held a career development course, "CSR (Intermediate Level)," for employees who have been with the company for about 10 years.

A total of 128 participants took the course, which covered knowledge on SDGs, ESG investment, and other CSR issues such as the environment, health and safety, Disaster Prevention and BCP.

These career development courses are positioned as mandatory training for promotion.

823 employees have participated in CSR training so far, or 16% of the Yokohama Rubber non-consolidated total.

In addition, in order to ensure that our managerial and supervisor level employees thoroughly understand ISO14001, we are conducting training classes for environmental internal auditors. Including 98 personnel who have completed this course to get certified in fiscal 2022, currently a total of 2,548 personnel have been registered and are already active as our internal auditors. (45% are qualified internal auditors in the scope of the integrated certification.)

We conduct skill improvement seminars to further improve the levels of employees with internal auditor qualifications. This time, due to the Corona disaster, it was not conducted.

Enhancement of Education Activities

As part of our environmental education activities, we conduct improvement activities by getting involved with all our personnel by sending our President’s message to all our employees in the Energy Saving Month in February and the Environment Month in June every year. For our Environment Month from June 1 to 30, we accept suggestions for environmental month slogans and posters from all Yokohama Rubber Group employees and family members up to elementary school student age.

In fiscal 2022, we resumed the campaign and received 5,902 entries for eco declarations and 110 entries for posters in Japan, and 6,629 entries for eco declarations and 403 entries for posters overseas.

Of these, the following were selected as excellent works.

In fiscal 2022, we resumed the campaign and received 5,902 entries for eco declarations and 110 entries for posters in Japan, and 6,629 entries for eco declarations and 403 entries for posters overseas.

Of these, the following were selected as excellent works.

| Japan | Overseas | |

|---|---|---|

| Environmental Slogan Excellent Works | 25 | 13 |

| Poster Excellent Works | 14 | 23 |

In addition, the best works were selected for both Japan and overseas.

Environmental Slogan Best Work

“Regular tire pressure checks improve fuel economy."

Toshiyuki Komura, PRGR

"When away from the plant, the equipment is shut down to prevent idling."

Yao Yubao, Production Section 1, CHZY

Toshiyuki Komura, PRGR

"When away from the plant, the equipment is shut down to prevent idling."

Yao Yubao, Production Section 1, CHZY

Environmental Poster Best Work

Chizuru Fujiwara, Bead, Manufacturing Section 1, Shinshiro Plant (Kazuya Fujiwara's family)

Naruemon, QC, YMTC

A commemorative gift was given by the secretariat for Excellent Works and Best Works in Japan and overseas.

President’s Award for Environmental Contribution

The Environmental Activity Awards were newly established in FY2022 with the aim of improving environmental management throughout the Group.

The award areas are "prevention of environmental pollution and spills," "reduction and elimination of chemical substances," "carbon neutrality," "promotion of resource recycling," and "contribution to biodiversity and local communities.

All divisions of the Yokohama Rubber Group are eligible for the awards, which are selected after reviewing and deliberating the activities conducted during the year for each case study in each field. Each award-winning division will receive an award from the General Manager of the CSR Division.

The award areas are "prevention of environmental pollution and spills," "reduction and elimination of chemical substances," "carbon neutrality," "promotion of resource recycling," and "contribution to biodiversity and local communities.

All divisions of the Yokohama Rubber Group are eligible for the awards, which are selected after reviewing and deliberating the activities conducted during the year for each case study in each field. Each award-winning division will receive an award from the General Manager of the CSR Division.

Environmental Accounting

Environmental conservation costs

Calculated since fiscal 2013 with the Head Office and domestic production bases as a boundary in reference to the environmental accounting guidelines issued by the Ministry of the Environment.

- (Millions of yen)

Move the screen to the left or right to see the table information

| Item | Major initiatives | FY 2021 | FY 2022 | |||

|---|---|---|---|---|---|---|

| Business area costs | Investments | Costs | Investments | Costs | ||

| Pollution prevention costs | Installation of deodorization equipment, supporting CFC regulations, etc. | 399 | 72.62 | 491 | 75.15 | |

| Global environmental conservation costs | Compressors, air conditioning renewal, adoption of hybrid forklifts, etc. | 257 | 30 | 110 | 65 | |

| Resource recycling costs | Costs related to waste segregation and processing | 0 | 507 | 0 | 523 | |

| Subtotal | 656 | 609 | 601 | 663 | ||

| Upstream and downstream costs | Expenses for reuse of tire bladders and plastics liners for rubber take-up | 0 | 63 | 0 | 63 | |

| Management activity costs | EMS maintenance, management, and information disclosure costs | 0 | 180 | 0 | 184 | |

| Research and development costs | Research and development costs for reducing the environmental burden | 282 | 868 | 79 | 875 | |

| Social activity costs | Tree planting activities in areas affected by the Great East Japan Earthquake, social contribution activities, etc. | 0 | 7 | 0 | 56 | |

| Environmental remediation costs | Reserves for PCB processing, etc. | 0 | 7 | 0 | 43 | |

| Subtotal | 938 | 1,734 | 680 | 1,884 | ||

| Total | 2,673 | 2,564 | ||||

Economic effect

- (Millions of yen)

Move the screen to the left or right to see the table information

| Type of effect | Major initiatives | FY 2021 | FY 2022 |

|---|---|---|---|

| Profits | Profits gained from wastes and recycling from business activities | 65 | 92 |

| Cost reduction | Cost reductions through energy conservation | 173 | 270 |

| Cost reductions through the use of recycled products | 464 | 726 | |

| Total | 702 | 1,088 |

Environmental conservation effects

Move the screen to the left or right to see the table information

| Year-on-year reduction | ||

|---|---|---|

| Type of effect | FY 2021 | FY 2022 |

| Greenhouse gas emissions (thousand tons, CO2) | -8,890.0 | -4,243.3 |

| VOCs emissions (tons) | -7.2 | -52.9 |

| Waste reclamation quantity (tons) | Zero emissions achieved domestically in FY 2010 | |

| Waste emissions (tons) | -681.3 | 833.3 |

Environmental efficiency

Greenhouse gas indicator

Index of sales/greenhouse gas emissions, with a value of 100 for the base year (FY 2005)

Index of sales/greenhouse gas emissions, with a value of 100 for the base year (FY 2005)

VOCs indicator

Index of sales/VOC emissions, with a value of 100 for the base year (FY 2005)

Index of sales/VOC emissions, with a value of 100 for the base year (FY 2005)

Industrial waste emission indicator

Index of sales/industrial waste emissions, with a value of 100 for the base year (FY 2005)

Index of sales/industrial waste emissions, with a value of 100 for the base year (FY 2005)