The Environment

Water and wastewater

KPI

Responsible Departments

Our position and Targets

Review of FY 2022 Activities

Introduction of Initiatives

Future challenges

KPI

Move the screen to the left or right to see the table information

| Item | FY 2021 results | FY 2022 results |

|---|---|---|

| Water intake | (Consolidated) 8,494 thousand m3 | (Consolidated) 8,247 thousand m3 |

| Percentage of recycled and reused water*1 | (Consolidated) 144% | (Consolidated) 155% |

| Total water consumption*2 | (Consolidated)14,252 thousand m3 | (Consolidated)14,695 thousand m3 |

| Water sources significantly affected by water intake |

(Consolidated) NA <Endangered species> There are endangered species in the Miya River (Mie), Kanogawa River (Mishima), and Kaname River (Hiratsuka) (red list of threatened species) <Intake of water from protected areas> Not applicable. There is no intake of water from protected areas. |

(Consolidated) NA <Endangered species> There are endangered species in the Miya River (Mie), Kanogawa River (Mishima), and Kaname River (Hiratsuka) (red list of threatened species) <Intake of water from protected areas> Not applicable. There is no intake of water from protected areas. |

- 1 Percentage of water recycled/reused = Amount of water circulated ÷ Ratio of water withdrawal

- 2 Total water consumption = total water withdrawal + circulated water - total wastewater (also considering circulated water)

Responsible Departments

Each business location

- Performance is managed by the Production Environmental Task Force.

Our position and Targets

Why is “Water” a critical issue to be addressed?

Explanation of the reason and background

The Yokohama Rubber Group use water in two ways; one is direct use, in which, water is used as cooling water for boilers and production facilities at production sites, and the other is indirect use, in which water is used by our suppliers to provide us materials and services.

Regarding direct use, the degree and composition of water risks vary (physical risk, regulatory-related risk, and reputation risk, etc.) depending on what geographical region our production site is located. Therefore, it is important for each site to effectively use precious water resources in line with the local condition.

In addition, for the indirect use of water in the production process for raw materials such as natural rubber as well, we think that it is necessary to take the appropriate responses as necessary after confirming the situation. This is based on our understanding that if it becomes impossible to procure raw materials due to water-related risks at suppliers, it could directly lead to serious problems that affect our operations.

Regarding direct use, the degree and composition of water risks vary (physical risk, regulatory-related risk, and reputation risk, etc.) depending on what geographical region our production site is located. Therefore, it is important for each site to effectively use precious water resources in line with the local condition.

In addition, for the indirect use of water in the production process for raw materials such as natural rubber as well, we think that it is necessary to take the appropriate responses as necessary after confirming the situation. This is based on our understanding that if it becomes impossible to procure raw materials due to water-related risks at suppliers, it could directly lead to serious problems that affect our operations.

Water use policy

Our domestic bases are blessed with rich water resources, which allows us to use water effectively as a recycled resource*. However, some of our overseas bases are located in areas with limited water availability. For this reason, it is necessary to conduct water risk assessment in each area where our site is located and work to ensure that water is properly managed by the site. We also find it is necessary to check the usage status of water at suppliers, and work together with each supplier to take countermeasures in the event that significant risks are found.

For this reason, after reviewing the situation from FY2015 to FY2017, we made a decision on our policy. We will also broadly disclose information on the progress of these efforts through various means such as external questionnaires (CDP water security questionnaire, etc.) and our website.

For this reason, after reviewing the situation from FY2015 to FY2017, we made a decision on our policy. We will also broadly disclose information on the progress of these efforts through various means such as external questionnaires (CDP water security questionnaire, etc.) and our website.

- We use water based on formal procedures such as agreements with each region (regional administration).

Water risk assessments

In production site areas using a lot of water, we use existing water risk assessment tools such as the WRI's Aqueduct to check the results of potential water risk assessment. We use existing tools and locally available information to make a comprehensive judgment on water risks.

Based on the obtained results, we identify the highest risk among representative water risks (physical risk, regulatory-related risk, and reputation risk, etc.) for each base, and consider what measures should be taken for them in descending order of priority.

Based on the obtained results, we identify the highest risk among representative water risks (physical risk, regulatory-related risk, and reputation risk, etc.) for each base, and consider what measures should be taken for them in descending order of priority.

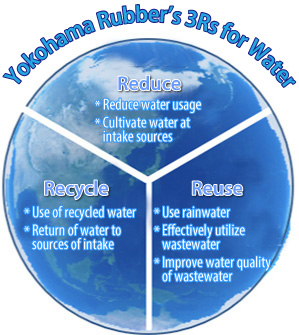

Vision and targets

We will promote 3R initiatives for water at all of our business sites, and in their areas including the supply chain, and strive to use water in a sound manner and conserve water resources. In this way, we will contribute to an appropriate water cycle on a global scale.

Measures for vision achievement

At domestic and overseas production sites, we conduct the following initiatives aimed at reducing the standard consumption unit of water intake by 1% year-on-year.

- Reinforce countermeasures to reduce water usage at the sites subject to higher physical risks (high water shortage probability).

- Thoroughly manage drainage water quality at the sites subject to higher regulatory risks.

- Enhance area communication at the sites subject to higher reputational risks.

Review of FY 2022 Activities

Transition of water intake and total water consumption are shown below.

In FY2022, water intake amounted to 8,247,000 m3, which is a 2.9% reduction from the previous year, despite increased production. On the other hand, total water consumption amounted to 14,695 thousand m3 with increased use of recycle water, resulting in 3.1% increase from 2021 level.

In FY2022, water intake amounted to 8,247,000 m3, which is a 2.9% reduction from the previous year, despite increased production. On the other hand, total water consumption amounted to 14,695 thousand m3 with increased use of recycle water, resulting in 3.1% increase from 2021 level.

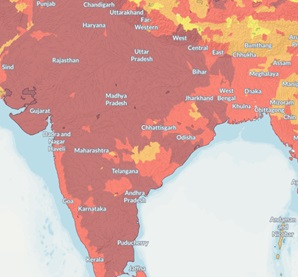

Water risk assessment is conducted by using results from existing water risk assessment tools such as the WRI's Aqueduct and locally available information to classify water volume risk (India and the Philippines), water quality risk (Japan, U.S., Thailand, Vietnam, Russia and Taiwan), and water volume and quality risk (China and Indonesia), and to conduct manage risks by country.

As a result of water stress assessment, it was found that areas with "Extremely High" or "High" water stress were China, India, the Philippines, Vietnam and Israel.

Water intakes of these countries and areas are shown below.

In FY2022, water intake amounted to 1,974,000 m3, resulting in 2.3% decrease from the previous year level.

As a result of water stress assessment, it was found that areas with "Extremely High" or "High" water stress were China, India, the Philippines, Vietnam and Israel.

Water intakes of these countries and areas are shown below.

In FY2022, water intake amounted to 1,974,000 m3, resulting in 2.3% decrease from the previous year level.

India water risk map

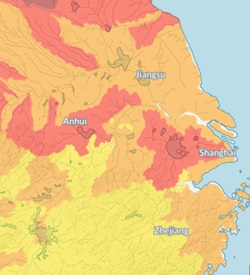

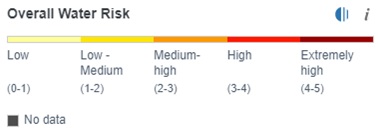

China water risk map

Source:Word Resources Institute Aqueduct Water Risk Atlas

[Examples] Level of water risk severity, based on data from the World Resources Institute (WRI)

[Examples] Level of water risk severity, based on data from the World Resources Institute (WRI)

- We made a report by responding to a questionnaire relating to the CDP Water program and the supply chain again in FY2022. The breakdown of water intake quantity is 65% in Japan and 35% overseas.

- We make effective use of water at all bases through continuously taking measures to prevent leakage and improving equipment for using recycled water. In particular, a closed water circulation system is being introduced to many overseas production sites to address physical (water shortage) risks.

- Regarding wastewater, we regularly check that the quality of the water being discharged does not pose any problems. We also make sure that such wastewater meets the water quality standards of the countries and regions where our bases a located.

Introduction of Initiatives

At our domestic production sites in Mie and Onomichi, we have made capital investments in leakage control of facility and facility pipes and equipment for using recycled water.

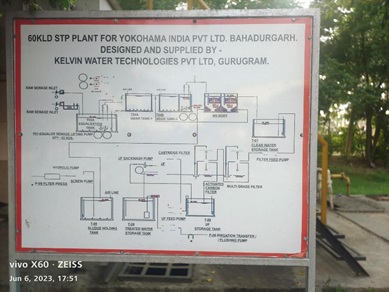

At our overseas production site in India, we introduced the closed system at the time of constructing the plant.

In Thailand and China, we collect rainwater and use it as cooling water and daily life water for restrooms.

In addition, water treatment facilities have been installed at production sites to prevent the deterioration of drainage water quality.

At our overseas production site in India, we introduced the closed system at the time of constructing the plant.

In Thailand and China, we collect rainwater and use it as cooling water and daily life water for restrooms.

In addition, water treatment facilities have been installed at production sites to prevent the deterioration of drainage water quality.

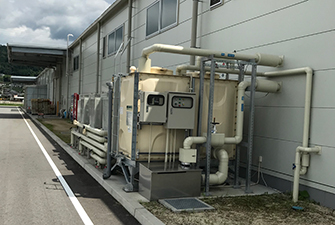

Water treatment facilities at our production base in Italy

At the Nagano Plant, a water circulating system has been introduced to recycle drainage water as cooling water, etc.

Nagano-water recycling system

On the other hand, we are conducting"biodiversity conservation activities" to examine the impact of drainage water on rivers in Mie, Shinshiro, Mishima, and Ibaraki, and examine its impact on the rivers serving as a source of well water in Hiratsuka.

Future challenges

We will build a system to ascertain data on global water usage status, and implement the following initiatives.

- Formulation of Yokohama Rubber Group standards (guidelines) for the proper water management

- Enhancement of awareness toward water-related initiatives and their necessity within the Company

- Joint implementation of initiatives for water use throughout the supply chain