What is Sustainable Natural Rubber?

What kind of resource is natural rubber?

What do you all imagine when you hear the word rubber?

Perhaps you think of something soft, stretchy, bouncy, not slippery, and that suppresses sounds and vibrations. It brings to mind many things, and they are all the properties that rubber has.

Rubber can be roughly divided into natural rubber and synthetic rubber. Natural rubber is made from plants such as the para rubber tree, while synthetic rubber is made from sources including petroleum. While it has only been used industrially for about the last 200 years, it is believed that natural rubber will play an increasingly important role in the recycling-oriented society of the future.

Natural rubber-producing para rubber trees

Today, most natural rubber used industrially is made by coagulating the rubber components contained in the latex collected by making incisions in the bark of para rubber trees (Hevea braziliensis). The main sources of natural rubber are the hot and humid tropical areas of Southeast Asia, Africa and Latin America. Among these regions, Southeast Asia is home to about 80% of the world's production.

Main uses of natural rubber

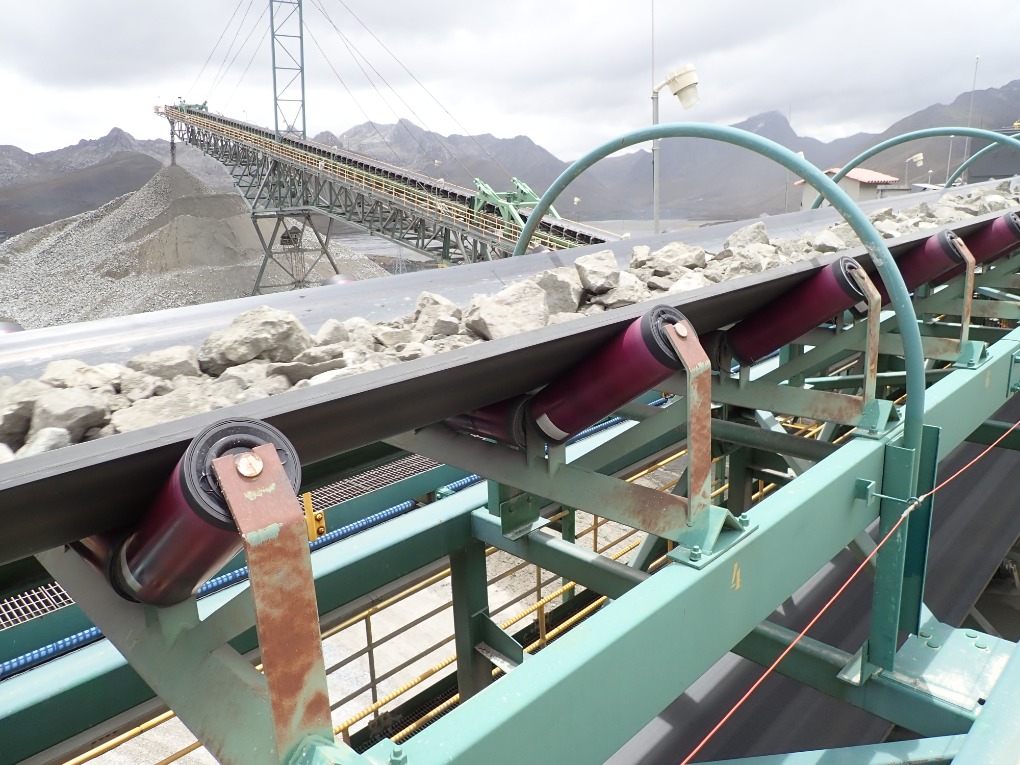

Natural rubber is used in tires, rubber bands, hoses, conveyor belts and other industrial rubber parts. It is used for variety of purposes, from the familiar to the uncommon, but about 70% is used in tire production. Due to its high strength, natural rubber is often used for large tires, especially those used for trucks, buses and industrial vehicles.

About 20% of the raw materials purchased by Yokohama Rubber are natural rubber

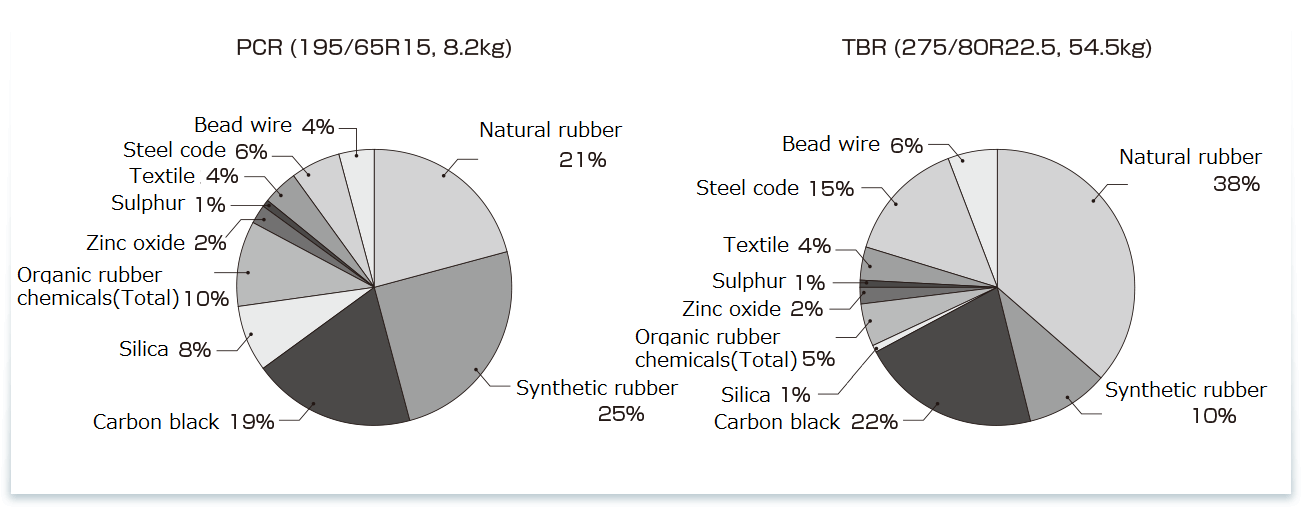

Yokohama Rubber makes a variety of products in addition to tires. Tires are often seen as black, round rubber products, but besides rubber, tires are made of a variety of materials and components including metal, fiber, carbon black and oil. Natural rubber is an important raw material that accounts for about 20% of the raw materials purchased by Yokohama Rubber.

There are various kinds of tires for passenger cars, trucks and buses, for vehicles that carry heavy loads or are used in harsh conditions, and for agricultural vehicles. Large tires that require durability often use natural rubber.

It is essential for Yokohama Rubber to secure a stable production of natural rubber for the foreseeable future in order to continue to stably supply products to our customers.

Natural rubber is an excellent resource

Para rubber trees absorb carbon dioxide from the air and make natural rubber that is used as a raw material for industrial products. It is also a natural carbon-positive resource (with CO2 absorption and fixation properties) because the para rubber trees store carbon within themselves. They also bring employment and income to natural rubber-producing areas, forming an industry that supports local economies.

Trees that no longer produce latex are cut down and used in furniture

In order to stably produce natural rubber of the same quality, para rubber trees grown in natural rubber plantations are made from clones with the same genes. Therefore, seedlings are usually made using cuttings from trees of the same family. It takes five to six years after planting for the seedlings to grow trunks thick enough to produce natural rubber. In addition, para rubber trees actively produce latex until about 20 to 25 years after they are planted and gradually produce less, making it necessary to replant regularly. Aged and felled para rubber trees are widely used in furniture and flooring. They are quite versatile.

Social risks at natural rubber plantations

Global natural rubber demand has nearly tripled over the last 40 years. This is due in large part to the growth in the global population and the rapid spread of motorization. On the other hand, there are concerns including about illegal deforestation, land deprivation and human rights violations, as well as the negative impact on biodiversity caused by deforestation and illegal logging.

Natural rubber plantations spreading in tropical areas with heavy rainfall

Of the areas where natural rubber is produced, Southeast Asia supplies about 80% of the world's supply. The rainforests in the region are vast. They are lands rich in biodiversity that are home to many rare creatures. The expansion of natural rubber and other plantations into such areas can affect the lives of invaluable living things. In addition, there are places that are threatened by illegal plantation development in natural parks and protected areas.

Instead of increasing the cultivation area to meet the increasing demand for natural rubber, it is important to increase production without diminishing tropical rainforests by increasing the yield per area and extending the production period, and to reduce the amount of natural rubber used by making products such as tires lighter and more compact.

Natural rubber grows between around 15 degrees latitude north and south of the equator

Overlap with global rainforests (green)

Major producers of natural rubber

Social issues including human rights and poverty

Natural rubber production is dominated by small holding plantations instead of large-scale plantations. It is said that there are six million farmers (smallholders) who grow natural rubber on small farms centered in Southeast Asia. These small farms are concerned about problems that include economic poverty, inefficient production due to the lack of knowledge, know-how and experience in rubber harvesting, and the increased burden on nature due to the lack of consideration for the environment.

Difficulty and importance of traceability

The price of natural rubber fluctuates in the international market. Dealers who have purchased raw rubber from natural rubber farmers check the market price for the day, and decide where to sell it or if they will store it in warehouses without selling. Although the latex from para rubber trees is extremely degradable, because raw rubber such as cup lumps made from hardened latex and unsmoked sheets (USS) can be preserved, it is traded from one dealer to another and across regions and borders depending on the circumstances. That is why it is very difficult to clarify the distribution route from producers to natural rubber processing plants (to ensure traceability). However, it is becoming more and more necessary to prove that purchased natural rubber was not produced on farms complicit in deforestation and human rights abuses.

Initiatives to make natural rubber a sustainable resource

Yokohama Rubber is taking steps to make natural rubber a sustainable resource in order to fulfill its responsibilities as a global tire manufacturer. Through these initiatives, we aim to clarify the kind of plantations where purchased natural rubber was produced (establishment of traceability), and to build framework that will enable sustainable production of natural rubber in the future by addressing the problems faced by regions and plantations, which will make it possible to sustainably produce natural rubber in those regions. We also want to use these activities to contribute to the SDGs.

Contributing to the SDGs through Actions for Sustainable Natural Rubber

Move the screen to the left or right to see the table information

| SDGs Goal | Goals and Targets |

|---|---|

|

1.End poverty in all its forms everywhere. |

|

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities. |

|

10.2 By 2030, empower and promote the social, economic and political inclusion of all, irrespective of age, sex, disability, race, ethnicity, origin, religion or economic or other status. |

|

12.2 By 2030, achieve the sustainable management and efficient use of natural resources. |

| 12.a Support developing countries to strengthen their scientific and technological capacity to move towards more sustainable patterns of consumption and production. | |

|

15.2 By 2020, promote the implementation of sustainable management of all types of forests, halt deforestation, restore degraded forests and substantially increase afforestation and reforestation globally. |

|

16.2 End abuse, exploitation, trafficking and all forms of violence against and torture of children. |

|

17.17 Encourage and promote effective public, public-private and civil society partnerships, building on the experience and resourcing strategies of partnerships. |

Signing and participating in international initiatives

In 2017 Yokohama Rubber announced its support for the goals of the Sustainable Natural Rubber Initiative (SNR-i) advocated by the International Rubber Study Group (IRSG), and began participating in SNR-i activities. Yokohama Rubber is also a founding member of the Global Platform for Sustainable Natural Rubber (GPSNR), initiated by the Tire Industry Project (TIP) of the World Business Council for Sustainable Development (WBCSD).

Revision of sustainable natural rubber procurement policy

The Yokohama Rubber Co., Ltd., revised itis Procurement Policy for the Sustainable Natural Rubber in September 2021. The revision incorporates the policy framework adopted by the Global Platform for Sustainable Natural Rubber (GPSNR) at its second general assembly held in September 2020 into the procurement policy established by Yokohama Rubber in October 2018. The revision is a further indication of Yokohama Rubber’s aim to contribute to the achievement of a higher level of natural rubber sustainability.

Overview of the Procurement Policy for Sustainable Natural Rubber

- Enhancing traceability

- Respect for human rights and prohibit any form of harassment

- Fair and equitable treatment

- Prohibition of child labor and forced labor

- Compliance

- Initiatives for zero deforestation

- Consideration for biodiversity

- Abiding by the principle of free, prior and informed consent (FPIC) in regard to land rights

- Creation of innovative technologies

- Communication with suppliers

Implementation of supplier meetings for natural rubber suppliers

The Yokohama Rubber Group held its 2nd Suppliers Day meeting for natural rubber suppliers since 2016. A total of 42 representatives of 25 companies in 5 countries attended the meeting, at which Yokohama Rubber requested the suppliers’ assistance in regard to the implementation of measures aimed at making natural rubber a sustainable resource, in line with our CSR policy; the Suppliers Day event helped to lead to strong mutual understanding with suppliers.

At the meeting, we explained the environmental aspects of our ESG mid-term plan and our human rights policy formulated in April 2022, and asked for cooperation in our efforts based on our "Sustainable Natural Rubber Procurement Policy" to deepen common understanding with our suppliers.

The president sent a message of appreciation to the suppliers for providing us with natural rubber of consistent quality, and presented trophies to suppliers who had made particular contributions to the company.

We also received a video message from Mr. Stefano Savi, Director of the Platform for Sustainable Natural Rubber (GPSNR), congratulating us on this event.

Suppliers Day