KPI

-

Item

Ratio of new suppliers that business was commenced with after conducting an environmental impact assessment

-

FY 2016 results

100% (159 companies)

-

FY 2017 results

100% (67 companies)

Item

Negative impacts in the supply chain and actions taken

FY 2016 results

―

FY 2017 results

We distribute our Green Procurement Guidelines when starting up business dealings and only initiate transactions after the supplier understands these guidelines.

Responsible Departments

Raw Materials Procurement Department, Indirect Materials Procurement Department, Global Procurement Division

Stance and Target

Why is “Supplier Environmental Assessment” a critical issue to be addressed?

Explanation of the reason and background

The raw materials used in the major products of the Yokohama Rubber Group contain many petrochemical products (chemicals) including various types of synthetic rubber that can cause environmental pollution and have a negative impact on the lives of local residents during the manufacturing process. Because the worst case can lead to suspension of operations at suppliers, we have selected environmental impact assessments of suppliers as a critical issue to be addressed from both the perspective of the stable procurement of raw materials and the perspective of ethics.

Environmental impact assessment at the start of new business relationships

When adopting new raw materials, it is confirmed whether the materials comply with various regulations, and suppliers are asked to submit documents to serve as evidence of compliance.

- Quality control survey form

- Raw materials standards

- Shipped materials inspection report

- Safety data sheet (SDS*) (the applicable raw materials are chemicals that include rubber compounding agents that SDS is applied to)

- Specific toxic chemical substances survey form

- Pledge of non-inclusion of substances prohibited by the European ELV Directive*

- Data proving non-inclusion of substances prohibited by the European ELV Directive*

- Four heavy metal substances survey form

In addition, we have issued the Green Procurement Guidelines that indicates the Green Procurement Policy of the Yokohama Rubber Group and our requests to suppliers in order to gain an understanding of these matters.

* SDS: Safety data sheets are international standard-forms to provide information on the characteristics and handling of chemicals when transferring or providing chemical substances or products (chemicals) that contain them.

* EU ELV Directive: An EU directive aimed at reducing the impact of end of life vehicles (ELV) on the environment.

Assessment of environmental impact in the supply chain

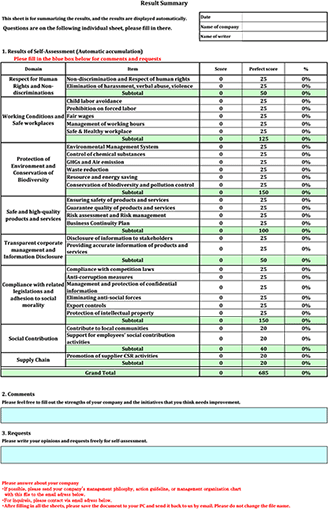

We ask suppliers to conduct a CSR self-check that includes a self-evaluation to report on matters including environmental management systems, substances of concern, and greenhouse gases. We revised the check sheet to further boost results in 2017.

CSR self-check sheet

Countermeasures in response to suppliers found to have a significant impact on the environment

While there have not been any such cases up until now, in such a case we will hold direct discussions with supplier plants on improvement points, causes, and improvement measures, and then implement these measures. We will suspend transactions in cases when improvements are not seen or malicious cases such as false reports.

Vision (attainment goal) / target

We started assessments with the new check sheet from 2017, and conducted self-check investigations of suppliers of main raw materials. Based on the results, we asked several suppliers to participate in workshops and carried out activities to deepen their understanding regarding CSR.

In 2018, we will carry out self-check investigations of overseas suppliers and expand our activities.

Measures for vision achievement

Study meeting have nearly been completed for procurement representatives at domestic and overseas business locations of the Yokohama Rubber Group.

In addition, by holding study meetings for domestic suppliers, we communicate the policies of the Yokohama Rubber Group towards requests to suppliers including those related to the environment and make an appeal for understanding of visiting audits. We will work to further expand the scope of such meetings going forward.

In fiscal 2018, we will once again hold Suppliers’ Day for suppliers of natural rubber to call for their cooperation in CSR. At the same time, we are now preparing to roll out a similar activity for all other suppliers.

Y.T. Rubber Co,. Ltd. (YTRC) of Thailand includes in basic trading contracts clauses on compliance including environmental protection and human rights, in an effort to promote CSR at natural rubber plantations.

Review of FY 2017 Activities

- Among all 67 new suppliers in Japan, there were no suppliers that caused an environmental impact.

- A CSR study meeting was held and attended by 364 persons representing 330 suppliers.

- All members of procurement departments received compliance training.

Number of companies that participated in CSR supplier study meeting (objective: more than 90%)

| Number of target companies* | Number of participating companies | Participation rate (%) | |

|---|---|---|---|

| FY2013 | 329 | 298 | 90.6 |

| FY2014 | 331 | 299 | 90.3 |

| FY2015 | 351 | 317 | 90.3 |

| FY2016 | 346 | 312 | 90.2 |

| FY2017 | 364 | 330 | 90.7 |

* Target companies: Medium and small-size companies with a certain level of transactions

Green procurement

Yokohama Rubber has been working on the development and usage of raw materials to contribute to the environment under the cooperation of our business partners with preservation of forest resources, control global warming, usage of recycled raw materials, and expansion of non-petroleum raw materials as the main themes.

Furthermore, we manage parts procurement based on the Yokohama Green Procurement Guidelines. We ask that all suppliers confirm whether products contain SOCs (substances of concern) and ask that they submit a statement of non-use.

We began participating in SNR-i activities that aim for the sustainable economics of natural rubber advocated by the International Rubber Study Group (IRSG) from 2017.

Reductions in CO2 emissions from shipment (promotion of local procurement adoption)

Further advances were made in the adoption of local procurement in at plants in China. In addition, we were able to switch from raw materials important from Japan to local procured goods at plants in North America as well. We were also advancing with the adoption of Russian raw materials at plants in Russia.

Changes in local procurement in Russia

Changes in local procurement in Russia

Changes in local procurement in China

Changes in local procurement in our Suzhou Plant

Changes in local procurement in our Hangzhou Plant

Yokohama Green Procurement Guidelines

With the management of chemical substances contained in products as a form of entrance control, we ask that suppliers work towards environmental preservation and manage procurement items in accordance with our Green Procurement Guidelines.

Furthermore, based on our Green Procurement Policy, we purchase raw materials, outsourced items, and subsidiary materials in accordance with environmental footprint standards.

Expansion of agroforestry plantations in Thailand

Y.T. Rubber Co., Ltd. (YTRC), a natural rubber processing company located in Thailand, supports the agroforestry plantation methods advocated by Professor Sara of Songkla University. YTRC is expanding initiatives to introduce this method to rubber plantations owned by neighboring farmers and the families of employees to validate its effectiveness.

Theory behind Professor Sara’s agroforestry method

- The following synergistic effects will be achieved by planting different tree species between the rows of natural rubber trees grown at plantations.

- Other trees will promote the growth of natural rubber trees increasing yield, extending their life, and reducing the amount of chemical fertilizers used

- Products harvested from other trees, such as fruit, bamboo and wood, increases farmer income

- Compared to conventional rubber tree plantations, trees can be maintained in a state that is close to a natural forest

From 2016, YTRC worked together with Professor Sara to provide guidance to and conduct verification on experimental plantations nearby. In addition, we regularly create organic fertilizer and supply it together with seedlings to nearby plantations and government agencies (Fiscal year 2017: 300 seedlings, 10 tons of fertilizer).

We are also conducting questionnaire surveys with natural rubber suppliers in Thailand to assess the state of natural rubber farmers and farms and to gather information on CSR activities that are being conducted.

Issues and Future Improvement Measures

Because the number of suppliers is also on the rise as our business expands, creating a database of supplier information including environmental impact is an urgent task.

In addition, we recognize keeping self-checks by suppliers uniform at a high level as an important issue, and accordingly we identify issues and use them as the main theme of study meetings as we work towards improvements. Furthermore, in order to promptly implement the above, we recognize the need to aim for further improvements in the level of procurement representatives at the domestic and overseas business locations of the Yokohama Rubber Group.

We also analyze the aggregated results of questionnaires with overseas suppliers of natural rubber, and consider countermeasures.