Yokohama Industrial Products Italy S.r.l. (YI-IT)

Production of off shore & in shore hoses

Total site area70,602 m2

Number of employees86 (as of December 2019)

LocationLocalità Tamarete, 66026 Ortona (Chieti province) - Italy

Contact for consultation and complaintsHuman Resources Department

TEL: +39-085-90338201 FAX: +39-085-90338401

Message from the General Manager

Steven Johnson

Ever since Yokohama Rubber established a plant in Ortona in 2014, we have focused on product quality control, and have raised the bar for tasks in all processes. In 2015, we introduced Design Review (DR) methods for the suitable management of work activities. We operated it by better clarifying the standards from lab tests and sample tests to certification for actual production, etc. In 2016, we introduced the “PYB methodology”, which analyzes the core factors in production nonconformances, and established preventive measures. This enables us to visualize the implementation status of recurrence prevention policies, etc., for quality issues.

Similarly, we are focusing on safety and the environment. We added anew drainage processing system to our existing rainwater management system to reduce our impact on the environment. Further, we devote utmost to finding outside businesses that will reuse waste rather than burying in a landfill. In addition, we are promoting the replacement of R22 (Chloro-di-fluoro-methane) gas. With regards to safety, YIIT is reconsidering Risk Assessment of working place, following YRC standards. This has led to an action plan aiming to reduce risk exposure on manufacturing and testing machines of YIIT plant. Great attention is given to the introduction of “Stop, Call & Wait” approach.

In 2019, YIIT successfully confirmed ISO 9001: 2015, ISO 14001: 2015 and OHSAS18001:2007 certification.

Organizational Governance

Reviews of organization and system

In order to better focus activity on strategic targets and allow expected financial outcome, the whole structure has been split intro different strategic pillars . Responsibilities were allocated to 3 management representatives for technical departments (Quality, manufacturing, Engineering, R&D), staff departments (R&D, Sales, Supply Chain, Finance and HSE) and Sales department. By taking such steps, we hope to demonstrate even higher synergies with Yokohama Rubber’s specialists, thus making even greater growth possible via strengthening the quality and cost competitiveness of our products.

Human Rights

Human rights and employment

YI-IT employs seven disabled people.

Further, we now permit part-time work following requests so that the household circumstances of individual employees can be taken into consideration.

We welcome foreign workers and cultures, starting with our British-born factory chief and Japanese-born deputy chief, and aim for cultural exchange.

We also create a whistle blowing system, available to all employees, to evidence possible cases of internal or external fraud.

Labor Practices

Yokohama Industrial Products Italy S.r.l. aims to satisfy the needs of our customers by supplying goods and services that satisfy the comprehensive requirements of quality, safety, and the environment.

Mission:To focus on environmental protection, pollution prevention, sustainability, and employee safety and health to be recognized as a leader in rubber hose design and manufacture through quality control of the petroleum products, chemicals, and petrochemical products that has handle, assuring reliability, and rigorously observing deadlines.

Scope:All organizations from the sales department described below to the selection of suppliers falls within our purview.

Organizations:Sales department (main customers and dealers), supply chain management department (suppliers, contractors), finance and accounting department, technical department, project management department, quality control department, production department, logistics department, safety, health, and the environment department, human resources department, Yokohama Rubber and its head office

Targets:

- Customer service

- Financial performance

- Profitability growth

- Raising the bar for human resources

Consequently, it is necessary for us to be involved in environmental policy and worker safety, and so are implementing the following activities according to our current policies.

- The promotion of effective policies on precautions, environmental protection, and accident prevention in the workplace according to laws, regulations, and the environmental and safety requirements applied for our business.

- Conformance to comprehensive management system (UNI EN ISO 14001 and OHSAS 18001) requirements.

- Periodic evaluations of the comprehensive system performance.

- The reviewing of safety and environmental targets at least once a year from the viewpoint of continuous improvement.

- The elimination of all nonconformance relating to safety and the environment.

- The implementation of correction and preventive measures to prevent the occurrence or recurrence of violations.

- The monitoring of work activities from the aspect of the environment and risks to minimize our environmental impact, and the implementation of activities to reduce workplace risks.

Consequently, we aim to achieve the following targets.

- Monitor and manage all environmental standard values

- Reduce waste

- Reduce the amount of resources used

- Reduce pollutants in waste water

- Reduce greenhouse gas emissions

- Improve the on-site work environment

- Minimize accidents

Involvement:

◆Compliance

We are actively and continuously improving quality, the environment, and safety comprehensively according to international standards ISO 9001: 2015, ISO 14001: 2015, and OHSAS 18001: 2007.

We respect our compliance obligations, legal requirements with regards to the environment and safety, and all other requirements agreed and adopted by our company.

◆Products and processes

We plan and implement process management and regulatory policies to prevent pollution, accidents, and industrial diseases, maintain quality standards, and meet customer requirements.

We use the 2S system to configure a corporate culture that promotes continuous research and waste reduction to reach the highest standards of cleanliness and flexibility.

◆Supplier and contractor management

We periodically audit our suppliers and contractors, and continuously implement improvement activities from both quality aspects that respect the environment and safety.

◆Resources and HR

We make sure that all staff, and central management in particular, understand and are involved in all practices to achieve our targets through keeping everyone informed, educated, and trained.

Occupational safety and health

OHSAS 18001 Certificate

The Environment

Environmental management

ISO14001 Certificate

First and foremost, we have it in mind to reduce the environmental burden of our operations.

YI-IT is reconsidering Risk assessment of all its own Company process risks (Fire risk, risk of incorrect waste management, risk related to atmosphere emissions, risk of water discharges, risk of dangerous liquid spills) in order to have a more detailed and updated monitoring of Company hazards.

YI-IT, on May 2018, has also received official authorization by Public Regional Authority for water disposal and air emissions.

Besides YI-IT is committed in reducing amount of disposed rubber improving the process of rubber reutilization.

Furthermore, as has already been stated, YI-IT successfully confirmed ISO140001: 2015 series.

Environmental data

Move the screen to the left or right to see the table information

| Category | FY 2015 | FY 2016 | FY 2017 | FY 2018 | FY 2019 | |

|---|---|---|---|---|---|---|

| Waste generated (t) | 0.0 | 131 | 110 | 134 | 54 | |

| Proportion sent to landfill (%) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Landfill waste (t) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Energy use (oil equivalent: kl) |

Electric power | 0.0 | 376 | 347 | 334 | 251 |

| Fuel | 0.0 | 404 | 357 | 370 | 295 | |

| Total | 0.0 | 780 | 704 | 704 | 546 | |

| Greenhouse gas emissions (1,000t-CO2) | — | 1.3 | 1.2 | 1.2 | 0.936 | |

| Water usage (1,000m3) | — | 17.2 | 11.5 | 14.3 | 9.9 | |

- FY: January to December

- Greenhouse gas emissions for the overseas site were calculated based on the Greenhouse Gas Protocol Initiative.

Fair Operating Practices

We aim for continuous contact and to maintain a cooperative relationship with our suppliers. Our main 18 suppliers are all in Europe. Every year, we set up an auditing schedule to encourage supplier growth from the aspects of quality and reliability.

We continuously authenticate and check our suppliers’ track records with the aim of surely and certainly achieving the targets required for supply.

A meeting taking place with business partners.

Group photo with business partner

Consumer Issues

YIIT managed the performance of the products in accordance of procedure PG18 “Customer satisfaction” and PG20 “PYB management”.

Considering the results of such analysis, in accordance with the annual policies that are set regarding quality, the environment and safety issues, we regularly undertake to establish quantifiable targets for improvement.

What is more, this company always focuses on the possibility of developing environmentally-friendly products.

As a result of being aware of and paying attention to such quality-related problems, in 2018, YIIT was able to confirm ISO 9001: 2015 certification.

A company booth at a trade exhibition.

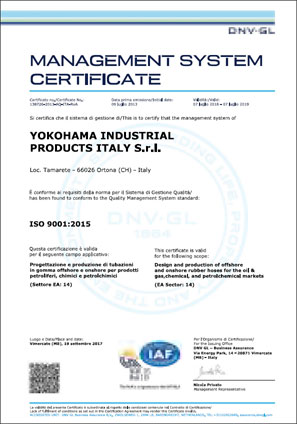

ISO 9001 Certificate

Community Involvement and Development

Ninety percent (90%) of our employees were born in Ortona. By hiring them, we are contributing greatly to local employment. On September 2019 local community celebrated 50th anniversary of the plant (building activity started on 1969). City mayor and old employees came to pay a visit to the plant, small ceremony was done and current Yokohama management was given a tag to celebrate the event. Furthermore, we support the karate and judo classes within our local community. Through offering training in the martial arts, these classes place a special focus on teaching local youngsters in their teens both about the value of participating in sport and developing a sense of respect for one another.