Suzhou Yokohama Tire Co., Ltd. (CSZY)

Production and sale of tires for passenger cars

Total site area201,500 m2

Number of employees938 (as of the end of December 2021)

LocationNo.158, Huaqiao Road, Xuguan Industrial Park, Suzhou National New & Hi-Tech Industrial Development Zone Suzhou, Jiangsu Province, 215151, China

Contact for consultation and complaintsTel: +86-512-6818-1008 Fax: +86-512-6818-1007

E-mail: xuejingyi @cszy.yokohamatire.com

Message from the President

Tomoyuki Okuno

Suzhou is famous for its rice, tea and freshwater crabs, known as Shanghai crabs in Japan, as well as its abundance of fish. Thus, many people from Japan also come here on sightseeing tours.

The plant began operations in 2008 as a truck and bus tire plant and added passenger car tire production in 2014. The plant, which completed production of truck and bus tires at TB plant in 2017 and was renovated to produce passenger car tires, began production in October 2019, and on October 12, 2019, the opening ceremony and the "Forever Forest" tree planting activity were held simultaneously. In addition, by November 2019, the plant will have achieved 10 million passenger car tires, and is expected to have an annual capacity of 4.46 million tires by 2021, including the renovated plant, as it continues to enhance its presence as a passenger car tire production base in China.

Our goal is to be a company that coexists in harmony with the local community by engaging in activities that contribute to the local community and take root in the community in this rich land. On the other hand, due to its affluent location, it is highly sensitive to the environment and its regulations are much higher than Japan's. Environmental measures for odors and VOCs are required at a high level. In addition, we will continue to participate in the release of fry into the lake, continue our tree planting activities in the Forever Forest, and promote biodiversity activities in the region.

Through our health and safety activities, we will help our employees feel that their safety is a family's happiness, and all of us will strive to become a company that is admired and trusted by everyone to achieve the goal of "becoming a “company that is attractive to both employees and regional communities.”

Organizational Governance

A Code of Conduct has been drawn up, which is printed on a card (together with the company’s policy) and distributed to all employees.

Workplace communication

Within the company, corporate decision-making is conducted through the holding of key meetings (including management meetings, cost meetings, safety meetings, environmental meetings, quality meetings, meetings of the human resources committee, minister's meeting, section chief's meeting, general manager's meeting and field morning meeting) on a periodic basis.

Human Rights

CSR education

We implement quarterly compliance training for managers of middle level engineer and above. All employees receive compliance training twice a year. Internal control-related education is provided for internal control team members. We publish a quarterly CSR plant magazine to disseminate knowledge on the subject.This year, we added legal education for specialized operations: for example, education on contract risk management, targeting purchasing and finance.

We invited outside lawyers to conduct job crime education for personnel at the elementary engineering master level and above in order to ensure that everyone is upholding the law.

CSR training has been conducted once/month for managers at the section manager level and above, as well as for worker representatives.

Grievance resolution

Based on the feedback from the government's environmental department, we are not only complying with emission control standards but also reducing the burden on the local community by improving environmental facilities while taking into consideration the local residents.

In 2021, new environmental facilities (RTO facility at Plant No. 2, deodorizing tower at vulcanization environmental facility, etc.) are being introduced to reduce the impact on the surrounding environment. Environmental facility management standards and standard operating procedures have been developed to improve management capabilities.

Since this project has had a positive effect, it is being expanded to Plant No. 1.

Labor Practices

Building a safe, healthy workplace environment

Slogan: Personal safety, family happiness (my safety is my family’s happiness)

We have passed the China Class 2 safety standard certification. We also passed an external audit for ISO 45001.

In addition, we proceeded with the creation of abnormal procedure manuals and created 124 new ones between January and December 2021.

We also carried out the following enhancement activities.

- Newly created and reviewed work standards

There are 105 new work standards created and 335 reviewed in FY2021. - 14 open work observations were conducted.

- 113 cases of internal occupational accidents and occupational accidents at other plants were developed and 60 countermeasures were implemented.

- Completed improvement of all 54 Risk III items. 44 of these were new items.

- To strengthen management of subcontractors, we conducted training for contractors three times (total of 92). We awarded a certificate of qualification for construction safety supervisor from our company.

We are improving the level of safety management through the continuous implementation of initiatives such as KYT, near-miss submissions, one-on-one education, periodic risk assessment, work observation and training, and review of work standards.

Labor safety and health

In accordance with China's national regulations, all employees who join, are enrolled in, or leave the company undergo occupational disease medical examinations, as well as workplace environment measurements and heat stroke training.

There will be no outbreak of occupational diseases in FY2021.

Labor relations

The company holds regular meetings with the labor union for the exchange of views.

We were awarded as an excellent company in Suzhou labor-management relations in 2021.

Human resources development and training

- Three-level safety training (plant/department/process level) is conducted for new employees, to certify them to work alone.

- Training for KYT instructors is conducted to strengthen their ability to implement KYT.

- Introduced high-temperature burn experience training equipment for regular training of enrolled employees.

- Safety training for all employees is conducted at the general manager's morning meeting in March, June, and October.

- Safety training for section managers to general managers was conducted. (2 times/year).

- Special fire prevention training was conducted. (For all employees. Safety personnel from outside contractors and resident contractor personnel also received training.)

Responses in case of disaster

We have an emergency contact system and first aid plan for safety incidents. In the event of a disaster, the emergency contact system is used to report to the general manager.

The first aid plan is immediately activated to deal with the disaster.

Each section conducts first aid drills. The contents of these drills include falling from a height, getting caught in a vehicle, collision with a towing vehicle, chemical leakage, etc. A total of 57 drills have been conducted.

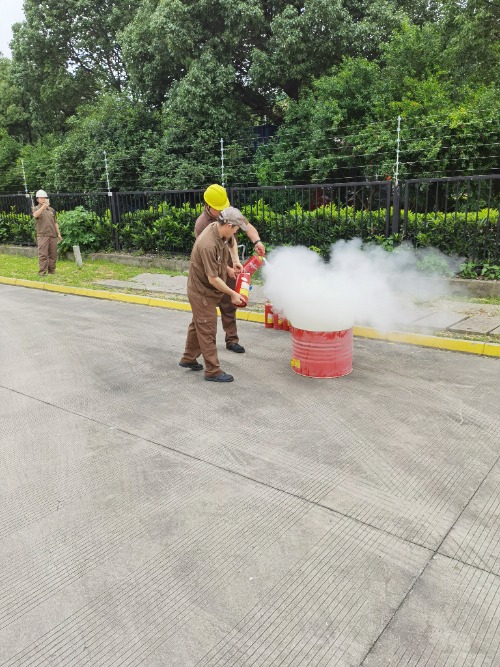

In 2021, evacuation drills against fire were conducted 6 times and fire drills were conducted 4 times.

Firefighting drills were conducted for resident subcontractor personnel, including security guards, cafeteria staff, and cleaning staff.

Firefighting drills for resident subcontractor personnel

Firefighting drills for resident subcontractor personnel

Firefighting training by volunteer firefighters

Firefighting training by volunteer firefighters

Evacuation training (daytime and nighttime)

Evacuation training (daytime and nighttime)

Fire Drill Contest

Fire Drill Contest

KY (hazard prediction) training, KY contest

KY (hazard prediction) training, KY contest

Open work observation

In-department work observation

Safety observation of new equipment

Safety patrols by the general manager

Managerial diversity

Managerial positions are filled not only through internal promotion from within the company, but also through outside recruitment. Currently, the company has 24 managers, of which one is a female department manager and three are section managers.

Employment of people with disabilities and promotion of employee diversity

There is a legal requirement that at least 1.5% of a company’s employees must be people with disabilities. Currently, CSZY has nine employees with disabilities. CSZY does not discriminate on the basis of gender in its recruitment and treatment of employees.

Of the total workforce of 938 employees (as of December 31, 2021), 108 were female employees.

The Environment

Environmental management

We have set out an environmental policy and comply with laws and regulations related to environmental protection, save resources, and implement preventive measures against pollution. In order to become a plant that is trusted by local communities, we operate an environmental management system, ISO 14001:2015, and are making improvements to our environmental facilities in consideration of the environmental impact on local residents.

Environmental data

Move the screen to the left or right to see the table information

| Category | FY2017 | FY2018 | FY2019 | FY2020 | FY2021 | |

|---|---|---|---|---|---|---|

| Waste disposed (t) | 529 | 554 | 885 | 651 | 1,504 | |

| Proportion sent to landfill (%) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Landfill waste (t) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Energy use (oil equivalent: kl) |

Electric power | 7,306 | 7,837 | 9,723 | 10,973 | 14,217 |

| Fuel | 3,324 | 4,152 | 4,861 | 5,820 | 7,593 | |

| Total | 9,688 | 11,457 | 12,698 | 15,543 | 21,810 | |

| Greenhouse gas emissions (1,000t-CO2) | 24.8 | 29.1 | 32.0 | 39.3 | 38.6 | |

| Water usage (1,000m3) | 111 | 117 | 133 | 175 | 232.1 | |

- FY: January to December

- Greenhouse gas emissions were calculated based on the Calculation and Reporting Manual for Greenhouse Gas Emissions jointly published by the Ministry of the Environment and the Ministry of Economy, Trade and Industry, Japan. Calculation of emissions from overseas business locations in FY2015 was based on the Greenhouse Gas Protocol Initiative.

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

Chemical substances are managed in accordance with the chemical substance management regulations of the Plant prepared according to the laws.

We have prepared the oil and chemical management guideline CSZY-EPD-017R02.

Noise and emissions

We conduct measurements four a year in accordance with the regulations of the regional government. With respect to all measurements that have been taken thus far, the environmental regulation values on all items fall within the specified scope.

As a result of both the national “Action Plan for Winning the Blue-Sky War,” and the three-year emission controlplan put forward by the Suzhou National New & Hi-Tech Industrial Development Zone, the regulatory environment regarding emissions has stiffened. In undertaking our business activities, the company has worked together with the Suzhou City administration in order to meet such demands.

Environmental activities

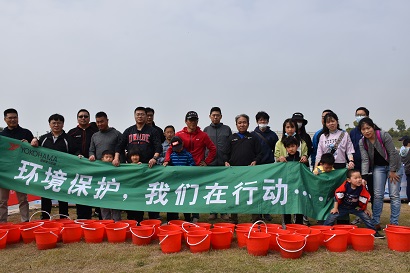

In FY2021, we participated in the Lake Taihu fry release activity. Other activities included biodiversity activities (twice), sapling tray sharing activities and tree planting activities at the Forever Forest.

April 24, protection of Lake Taihu and fry release activity held by the Environmental Association.

On May 22, the 12th biodiversity survey activity was held. A total of 111 people participated, including 103 students and parents from Yangshan Experimental Elementary School and Tongan Center Elementary School, 6 CSZY employees, and 2 from the Environmental Association.

On June 25, 15 employees conducted a seedling-dispersing activity at the Forever Forest. A total of 700 seedlings were divided, including Huangshan tree gentian, Chinese waxwing, camphor tree, and small-leaf mouse glutinous rice glutinous rice.

On Nov. 4, to help new employees understand the activities of the Forever Forest, we gathered new employees and planted 225 seedlings in the seedling area at Plant No. 2.

The 13th biodiversity activity was held. Twenty-four new employees participated in this event, conducting biodiversity surveys, measuring seedlings, and picking up seeds.

Fair Operating Practices

Corruption prevention

CSZY is working to promote effective personnel rotations and other measures in order to make the flow of goods, information and money more transparent.

Each month, the Internal Control Office conducts an operational audit, and it establishes whether or not each of the subject operations is being carried out in accordance with instructions. Such work also seeks to verify the suitability of those operational processes that are subject to audit measures. Furthermore, the company is also working to build up a mutual surveillance structure through the organizing of whistle blowing systems and the installation of suggestions boxes, etc.

In 2021, we implemented the second step of internal control operations, organizing work flow, risk identification, and risk improvement in the product warehouse, equipment warehouse, and raw material procurement section. Currently, we have completed 45 levels of risk improvement.

Responsible participation in political affairs

Besides reporting to the relevant company committees all matters relating to revisions in the law, regulations or ordinances, once such has been scrutinized by the Internal Control Office, the company asks its attorneys for legal advice regarding all matters that relate to various contractual obligations or require specialist know-how.

Regularly collect laws related to company management and send them to relevant departments. Ensure compliance with laws during the implementation of each operation.

Fair competition

With respect to suppliers (both domestic and overseas) seeking to engage in business transactions with CSZY, the company provides fair, impartial opportunities for participation in an open manner.

Promotion of social responsibility within the company’s scope of influence

We provide open, fair, and equitable entry opportunities for domestic and foreign suppliers who wish to do business with us.

Respect for intellectual property rights

We provide open, fair, and equitable entry opportunities for domestic and foreign suppliers who wish to do business with us.

Consumer Issues

Ensuring product quality and product safety

In line with our quality policy of “Providing consistently high- quality products so that customers all over the world can purchase our products with complete peace of mind,” we implement our quality management system effectively in accordance with the IATF 16949:2016 standard and customers’ requirements.

In 2021, we received 4 OE audits and passed all of them. In particular, we were able to receive a green rating from BMW for both audits. We also passed Mazda's AA audit.

Improvement activities to prevent recurrence and preventative measures were carried out as planned. In order to improve inspection accuracy, we were able to reduce the rate of missed inspections by improving the inspection environment, methods, standards, and inspector certification methods.

Improving after-sales services and customer satisfaction

Tire quality not only meets YRC standards, but also the quality standards of our local customers.

No related quality issues occurred in FY2021.

Education and awareness-raising

To raise quality awareness among all employees, quality prediction training (QYT) was conducted once per day at each process, SOPs and other rules were correctly understood and followed, process improvements were made from the customer's viewpoint, and quality on-site follow-up was conducted by the general manager.

In April 2021, quality awareness training was provided to managers and team leaders, and in November, all employees received quality fraud prevention training.

In addition, the following activities were conducted as part of Quality Month activities.

(1) PFMEA risk analysis improvement activities

(2) QYT contest

(3) FM reduction activities

(4) Quality patrol

(5) OPL contest

Community Involvement and Development

Participation in local environmental activities

February 4, 2021 A total of 20 students from Wenxing Elementary School and their families participated in the Environmental Protection Winter Camp. They conducted "Save the Forest, Save the Paper" classes, seed picking, and bird watching. We taught students environmental knowledge and increased their environmental awareness.

On February 5, a total of 35 students and their families from the East Nagisa Experimental Elementary School participated in the Environmental Protection Winter Camp. The camp included lessons on "Protecting Forests, Saving Paper," seed picking, and bird watching. The students were taught environmental knowledge and improved their environmental awareness.

On the afternoon of March 12, 2021, a total of 21 students (15 students and 6 teachers) from Keion Experimental Elementary School participated in CSZY's tree-planting ceremony. During the tree-planting ceremony, they visited CSZY's exhaust and wastewater treatment facilities.

Plant tours

Applications for plant tours are accepted at any time by the Administration Department in accordance with the "Rules for Accepting Visitors”.