Hiratsuka Factory (HP)

Design, basic research, development and evaluation of aircraft parts, sporting equipment, adhesives and sealants, conveyor belts, marine hoses, fenders and other industrial products

Total site area255,811 m2 (including Adhesives and Sealants Plant)

Number of employees1,903 (as of December 2021)

Location2-1, Oiwake, Hiratsuka City, Kanagawa 254-8601, JAPAN

Contact for consultation and complaintsGeneral Affairs Group, Hiratsuka Factory Tel: +81-463-35-9501 Fax: +81-463-35-9746

Message from the General Manager

Takashi Shirokawa

While continuing to serve as a “base for the dissemination of technologies and monozukuri manufacturing expertise throughout the Yokohama Rubber Group,” the Hiratsuka Factory is also aiming to be a “factory that maintains the affection and unwavering trust of both customers and the community,” in line with Yokohama Rubber’s CSR Vision. Within this strategic framework, in the environmental sphere the Hiratsuka Factory is focusing in particular on reducing leakage and noise pollution, which can have a pronounced negative impact on the local environment, to zero, while in regard to safety the Hiratsuka Factory will be striving to eliminate accidents that are serious enough to require employees to take time off work, by ensuring that everyone who works at the Hiratsuka Factory puts safety first; in addition, as a factory belonging to a company that plays a key role within the automotive industry, the Hiratsuka Factory will also be seeking to reduce road accidents in which people are injured to zero. In terms of disaster prevention, we are working to improve the level of fire and disaster prevention based on our internal guidelines, and to build a BCP to prepare for disasters as a priority issue.

Furthermore, in every aspect of our business operations our actions will embody not only strict adherence to compliance-related regulations, we also act with the motto of "coming home with a smile every day" with an awareness of compassion for people, customer satisfaction, employee satisfaction and social contribution.

In FY2021, as in the previous year, activities will continue to be conducted within COVID-19, and unfortunately we have had to cancel various events that serve as opportunities for exchange. Despite these circumstances, we are continuing to carry out steady activities within the company, such as seedling cultivation at the Millennium Woods.

We are also making preparations for the relocation of our head office to Hiratsuka in 2023. We will proceed with construction so as not to inconvenience our neighbors, and at the same time, we will make preparations to create an office that will be appreciated by our employees who will commute to Hiratsuka, our customers, and the local community.

We will also continue to engage in various CSR activities to contribute to the development of the Hiratsuka area.

Organizational Governance

Publicizing and sharing policies and issues

In that it represents a combined location, the Hiratsuka Factory hosts multiple business departments, production plants and R&D facilities. Close attention is thus paid to thoroughly publicizing policies and issues that involve the entire factory. We also strive to improve communication.

We strive for smooth plant management by making the director's policies and safety and environmental policies known at the plant-wide morning meeting each term, and by making various performances known and sharing topics, etc. at the monthly plant meeting.

Improved functionality through management systems

We appropriately operate safety and environment in accordance with OSHMS and ISO 14001 management systems. We also implement continuous improvement through the PDCA cycle in the management system.

Labor Practices

To ensure compliance with laws and regulations, we conduct monthly compliance training for each department, striving to increase employee knowledge and awareness.

In addition, in order to realize appropriate working hours, labor and management check working hours, etc., and the top management of labor and management conducts patrols to ensure proper management of work styles.

Furthermore, to improve the workplace environment, labor and management discuss items for improvement and promote improvements. In response to COVID-19, remote work is encouraged and a remote work environment has been created. Through these various measures, we are continuing to create an environment in which employees can work with peace of mind.

Promotion of gender equality

In fiscal 2021, the ratio of female staff in career-track positions stood at 20.6%.

We will continue to promote the hiring of female employees and promote work-life balance through the use of childcare leave and shorter working hours, the use of hourly paid leave system, flextime system and telecommuting system.

Promotion of employment of people with disabilities

As of the end of December 2021, the employment rate of persons with disabilities was 3.20%.

We will continue to promote the employment of people with disabilities and work to create a workplace environment where people with disabilities can work with vigor and enthusiasm.

Occupational safety and health management

Since the Hiratsuka Factory acquired Occupational Safety and Health Management System (OSHMS) certification in July 2010, we have conducted OSHMS-based occupational safety and health management. This work has been mainly built around continuous risk assessment and KY (Hazard Prediction) activities, etc.

When new operational processes are introduced or changes are made to existing operations, we hold “open work observations,” which allow many employees to witness work practices and identify hidden risks. We do this so as to further work improvement that makes work practices even safer.

Furthermore, we comply with safety and health statutory requirements, and proactively promote both employees’ acquisition of qualifications and educational activities. We also work to develop human resources and prevent disasters.

Traffic Safety

In order to reduce the number of traffic accidents, we provide traffic safety guidance and conduct road safety seminars for all employees twice a year. Each month, we conduct traffic safety education and other activities at each workplace.

Furthermore, we have designated the first day of every month as "Traffic Safety Day" at the Hiratsuka Plant, and are enhancing the traffic safety awareness of all employees through broadcasts within the plant. We are aware of our responsibility as a company that plays a part in the automotive industry, and are working to prevent traffic accidents.

Health management

We follow up to ensure that 100% of our employees receive the various medical examinations required by law, including regular medical checkups and special medical checkups.

We also provide mental health care to employees who have concerns about their work or life by offering counseling opportunities by professional counselors.

As a countermeasure against COVID-19 infection, we have implemented all the usual measures and conducted corona vaccine inoculations at workplaces.

The Environment

Environmental management

The Hiratsuka Factory continues to operate environmental management based on ISO 14001 environmental management system certification, which was acquired in July 1999.

From fiscal 2012, it converted to an environmental management system integrating the entire company as one site of Yokohama Rubber. We will continue to deploy activities based on the company-wide environmental policy.

As the Hiratsuka Factory holds a wide range of business organizations, from plants with different production methods to the technical research and development department of the entire company, it divides them into 9 environmental blocks to advance daily environmental improvement activities under the Hiratsuka Factory Environmental Policy in compliance with the company-wide environmental policy.

Environmental data

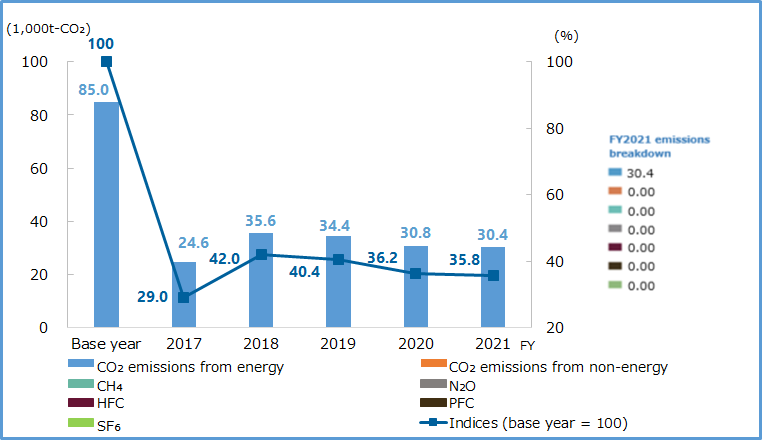

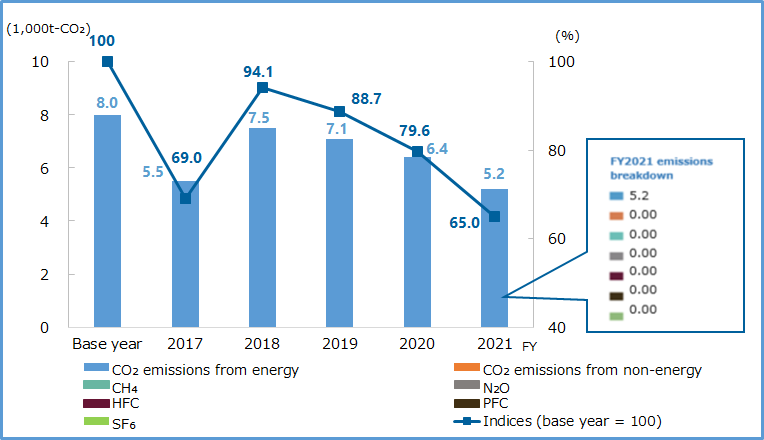

Reduction of greenhouse gas emissions

Greenhouse gas emissions

- The base year is defined as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Method of calculation of greenhouse gases (GHG): this is in compliance with the “Calculation and Reporting Manual for Greenhouse Gas Emissions” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Note that GHG emissions associated with purchased power in FY2009 were calculated using the Table of Emission Coefficients by Power Company (Ministry of the Environment).

- The base year is defined as 1990 except for HFC, PFC and SF6, where the base year is 1995 as per the Kyoto Protocol.

- Method of calculation of greenhouse gases (GHG): this is in compliance with the “Calculation and Reporting Manual for Greenhouse Gas Emissions” issued by the Ministry of the Environment and the Ministry of Economy, Trade and Industry.

Note that GHG emissions associated with purchased power in FY2009 were calculated using the Table of Emission Coefficients by Power Company (Ministry of the Environment).

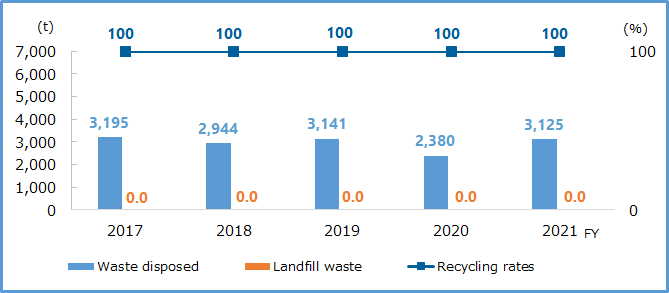

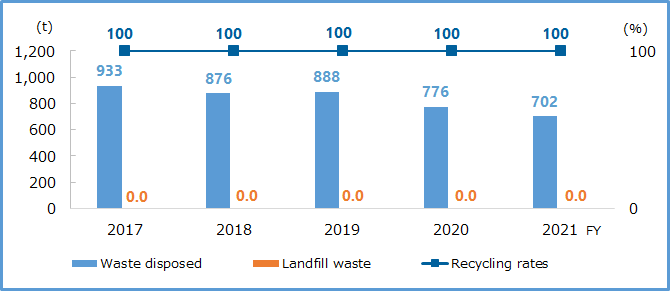

Effective use of resources / Reduction of waste

Waste output

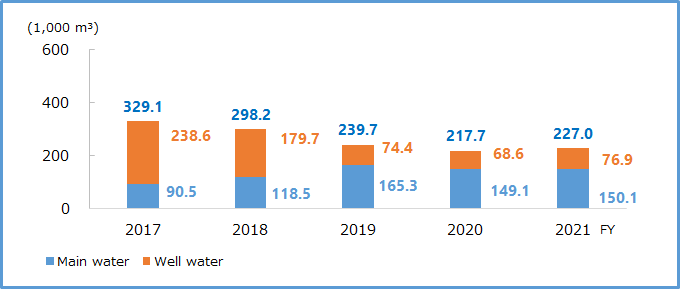

Water Usage

Measures for discharges into water, air and soil

Data related to water contamination

Move the screen to the left or right to see the table information

| Drain | Item | Regulatory values | Voluntary standard values | FY2021 results | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Hiratsuka Factory | pH | 5.0~9.0 | 5.18~8.7 | 7.7 | 8.3 | 7.0 |

| BOD concentration (mg/l) | 600 | 430 | 60 | 170 | 11 | |

| SS concentration (mg/l) | 600 | 190.0 | 31 | 74 | 2 | |

| Animal and plant oil concentration (mg/l) | 30 | 15.0 | 3 | 6 | 1 | |

| Mineral oil concentration (mg/l) | 5 | 3.1 | 1 | 2 | 1 | |

- In accordance with the Hiratsuka Municipal Sewerage Ordinance.

Air pollutants (NOx, SOx)

Move the screen to the left or right to see the table information

| Substance | NOx emissions (t/year) | SOx emissions (t/year) |

|---|---|---|

| Hiratsuka Factory | 3 | ― |

| Facility | Substance | Regulatory values | Voluntary standard values | FY2021 results | ||

|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | ||||

| Hiratsuka Factory Boilers 1 |

Nox (ppm) Soot and dust (g/h) |

150 635.4 |

31.0 51.9 |

45.0 9.3 |

23.0 5.0 |

22.0 4.3 |

| Hiratsuka Factory Boilers 2 |

Nox (ppm) Soot and dust (g/h) |

150 635.4 |

31.0 51.9 |

46.0 9.4 |

24.0 4.7 |

22.0 4.7 |

| Hiratsuka Factory Boilers 3 |

Nox (ppm) Soot and dust (g/h) |

150 635.4 |

31.0 51.9 |

46.0 8.5 |

24.0 4.3 |

22.0 4.2 |

| Hiratsuka Factory Boilers 4 |

Nox (ppm) Soot and dust (g/h) |

150 635.4 |

31.0 51.9 |

43.0 9.1 |

22.0 4.8 |

21.0 4.3 |

| Hiratsuka Factory Boilers 5 |

Nox (ppm) Soot and dust (g/h) |

150 635.4 |

31.0 51.9 |

46.0 7.8 |

24.0 4.2 |

22.0 3.6 |

| Hiratsuka Factory Boilers 6 |

Nox (ppm) Soot and dust (g/h) |

150 635.4 |

31.0 51.9 |

44.0 9.1 |

22.0 4.8 |

22.0 4.3 |

- In accordance with the Air Pollution Prevention Law and Kanagawa Prefectural Ordinance.

Reporting on chemical substance management status (Pollutant Release and Transfer Register (PRTR) Law compliance)

The Hiratsuka Factory verifies whether secondary materials and auxiliary materials contain chemical substances subject to Safety Data Sheet (SDS)requirements, and in the case of substances where the amounts handled exceed the thresholds specified by the PRTR Law, annual reports are submitted to the national (or prefectural) authorities and safety impact assessment is performed.

Regarding the handling of substances pursuant to the PRTR Law, please refer to the Safety Evaluation Table of Domestic Production Bases.

Pollution prevention

We have established self-administered values that are even stricter than regulated targets so as to strictly observe all environmental laws and ordinances concerning air pollution, water contamination and noise, etc. We take steps to monitor and measure these values.

Furthermore, to ensure that no sensory discomfort resulting from noise, vibrations and odors, etc. is caused to neighborhood residents, we have established monitoring points outside the factory grounds and are working to prevent such issues.

With respect to PCB waste within the factory, it is suitably handled in accordance with the relevant laws and regulations.

Use of sustainable resources

We are taking steps to reduce overall volumes year-on-year by placing a top priority on the goals and targets of the ISO 14001 management system with respect to reductions in industrial waste, organic solvents, greenhouse gas emissions and water usage.

Alleviating and adapting to climate change

During "Energy Saving Month" in February and "Environment Month" in June, we set up priority measures in each of our original operations and report on energy saving achievements, while division managers of each block conduct environmental patrols.

On February 3, 2022, Yokohama Rubber's Hiratsuka Factory received the "FY2021 Kanto Bureau of Economy, Trade and Industry Director-General's Award for Excellent Energy Management Businesses" from the Kanto Bureau of Economy, Trade and Industry, Ministry of Economy, Trade and Industry.

The award is given to outstanding enterprises in the 10 prefectures of Tokyo that are under the Kanto Bureau of Economy, Trade and Industry's jurisdiction that have made outstanding efforts to promote energy management, and that have achieved significant results and set a good example for others to follow.

The Hiratsuka Plant received the award for its excellent energy conservation performance over the past five years, advanced energy conservation improvement activities as typified by "boiler system improvement," and awareness, dissemination, and guidance of energy management technology outside the company (industry associations, etc.).

Environmental protection, recovery of natural habitats

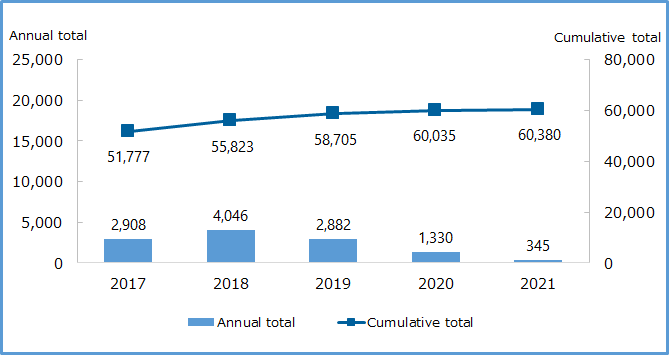

Since fiscal 2013, we have been conducting biodiversity conservation activities to protect water resources in the local Kaname River system.

Employees have participated in a series of hands-on monitoring activities to examine the environment of the Kaname River, with a cumulative total of 346 employees taking part.

Currently, activities are being conducted in a satoyama in the city located upstream of the Kaname River.

Specifically, with the objectives of recharging the water source of the Kaname River and restoring the original landscape of the satoyama, we are conducting conservation activities in collaboration with local groups and university laboratories, including the installation of handmade biotopes, and monitoring changes in the ecosystem.

Furthermore, since FY 2017, we have installed a dragonfly pond on the Hiratsuka Factory premises as a familiar activity site to observe the connections among dragonflies and other living creatures.In March 2017, the Hiratsuka Factory received the " Association for Business Innovation in Harmony with Nature and Community Certificate® (ABINC certification)" as a biodiversity-conscious plant in recognition of these biodiversity activities and the ongoing CO₂ absorption and fixation amount survey conducted in conjunction with the growth of the Yokohama Forever forest planted around the plant in 2007.

Fox photographed in a satoyama (semi-threatened species in Kanagawa Prefecture)

A damselfly at the dragonfly pond

ABINC logo mark

Fair Operating Practices

Impartial and fair selection of business partners

To ensure fair selection of suppliers, we conduct a survey on whether or not there are any personal relationships between the targeted suppliers and our employees when we hire new suppliers.

Other selection is based on economic rationality, taking into consideration the supplier's quality, price, supply stability, technological development capabilities, and CSR and environmental considerations.

Establishment of a “Procurement Code of Conduct” and its thorough implementation

With the “Basic Procurement Policy”, we prepared the “Procurement Ethics (Rules for Procurement Staff)” to indicate matters to be noted by procurement staff when conducting fair and impartial transactions and unethical practices that must not be engaged in. These ethics were combined with the “Basic Procurement Policy” to become the “Procurement Code of Conduct”.

We are working to ensure comprehensive awareness of compliance issues through workplace-based classes, which are held on a regular basis.

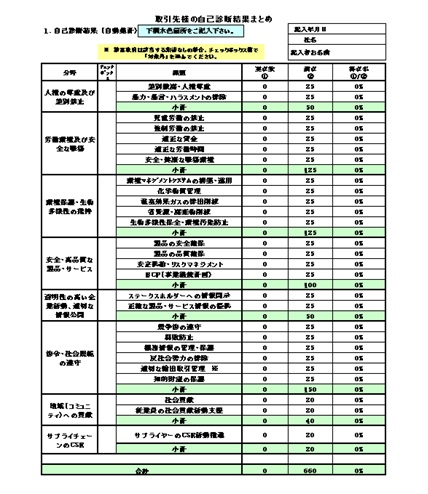

Deployment of CSR activities for business partners

For 2021, we had previously held the workshop in a face-to-face and written format, but decided to forego it in light of the COVID-19 situation. As an alternative, we distributed CSR self-assessment sheets to suppliers, asking them to check the status of their CSR activities and to use them as a basis for future CSR activities.

This time, 391 suppliers of the Hiratsuka Factory responded.

Consumer Issues

When purchasing stationery items that are to be used in our plants, we focus on buying products that are eco-certified and listed in the Green Purchasing Network (GPN) database.

We continue to purchase about 90% of our requirements through such means, buying sustainable products that place little burden on the environment.

Community Involvement and Development

Regional activities

We have continuously participated in volunteer activities organized by local groups, such as tree planting and riverbank cleanup, but unfortunately we refrained from such activities in fiscal 2021 due to COVID-19.

Disaster-prevention activities

Unfortunately, due to the effects of COVID-19, the annual fire-fighting competition organized by the Hiratsuka City Hazards and Safety Committee was cancelled in fiscal 2021. We also refrained from activities in cooperation with the local community, such as supporting disaster drills at the Hiratsuka School for the Visually Impaired, which is located adjacent to the Hiratsuka Factory and with which we have a disaster countermeasure cooperation agreement.

On the other hand, the annual disaster drills at the Hiratsuka Factory were conducted in the form of desktop drills to prevent the spread of COVID-19.

Regional contributions

- We continue to support Shonan Bellmare, a local J-League team, under our CSR partnership agreement.

- Once a month, employees carry out cleaning activities around the perimeter of the factory, while taking care not to make the area too dense because it is located under COVID-19.

Regional exchanges

Think Eco Hiratsuka

Unfortunately, the event was cancelled in FY2021 in consideration of preventing the spread of COVID-19, but we posted information on the activities on the fence around the perimeter of the plant for the local residents who look forward to this event to look back on the past activities and move on to the next. We also set up a special website on our official website to disseminate information about our ECO activities both inside and outside the company.

Results of a questionnaire survey about our local communication events

In consideration of preventing the spread of COVID-19, we have cancelled the regional communication meeting.

List of FY2021 Regional Contributions / Community Activities

Hiratsuka Factory History Tour

We have decided to cancel the Hiratsuka Factory history tour in consideration of preventing the spread of COVID-19.

Volunteer activities

In consideration of preventing the spread of COVID-19, various volunteer activities have been cancelled or refrained from.

Provision of Yokohama Forever Forest seedlings (Total: 1,693 seedlings)

April and September 2021: 345 seedlings for social welfare corporations

April 2022: 1,348 seedlings for social welfare corporations

Support for education

We support Hiratsuka School for the Deaf and Hiratsuka School for the Blind as a member of their school management council.

Local event support, donations, and participation

We refrained from activities due to COVID-19.