The Environment

Materials

KPI

Responsible Departments

Stance and Target

Review of FY 2021 Activities

Issues and Future Improvement Measures

KPI

Move the screen to the left or right to see the table information

| Item | FY 2020 results | FY 2021 results |

|---|---|---|

| Total volume of raw materials used | (Consolidated) 899,000 tons | (Consolidated) 1,068,000 tons |

| Ratio of renewable/recycled raw material | (Consolidated) 25.8% | (Consolidated) 25.5% |

Responsible Departments

Technology and design departments

- Supervised by the 3Rs Committee

Stance and Target

Why is “Materials” a critical issue to be addressed?

Explanation of the reason and background

Yokohama Rubber Group sells products using chemicals and natural capital such as natural rubber and water. These raw materials are made from the Earth’s natural resources, and they are by no means infinite. Accordingly, we view using minimal raw materials, promoting the sales of recycled products (such as retread tires), and the delivery of products that will please customers and society using recycled raw materials (such as regenerated rubber powder) to be important issues.

Policies and stance relating to raw materials

The Yokohama Rubber Group has presented its environmental philosophy in the Yokohama Rubber Basic Environmental Policy and Yokohama Rubber Environmental Policy, and will work to develop and procure raw materials that lead to minimizing of the burden on the environment, and to minimize usage volumes of raw materials from natural resources in accordance with the Yokohama Rubber Group Action Guidelines.

Vision (attainment goal) / target

Long-term target: 100% sustainable raw materials usage by 2050

Mid-term target: At least 30% renewable/recycled raw material usage by 2030

Mid-term target: At least 30% renewable/recycled raw material usage by 2030

Measures for vision achievement

We will develop and use raw materials with a reduced burden on the environment and society through the following initiatives in order to achieve business continuity.

We will also establish a procurement system for sustainably available raw materials with the lowest environmental and social impact throughout their life cycles.

We will also establish a procurement system for sustainably available raw materials with the lowest environmental and social impact throughout their life cycles.

- We will review factors such as structural design and material rigidity to fulfill the required performance while achieving weight reductions.

- We will work to promote sales of retread tires.

- Furthermore, we will develop tires and belts with a high regenerated mixture ratio, and reusable products.

Review of FY 2021 Activities

Expanding the Use of Renewable Raw Materials Toward a Recycling-Oriented Society

We have long been promoting the use of renewable and recycled raw materials as part of our efforts to realize a recycling-oriented society (circular economy).

In addition to the use of recycled rubber, which we have been working on, we are expanding the use of a wide variety of renewable and recycled raw materials, such as silica made from plant-derived and inedible rice husks, resins derived from natural materials, and wires made by melting and reusing scrap iron.

The weight of conventional recycled rubber and non-petroleum-derived polymers used has increased by more than 110% compared to last year. The use of silica made from rice husks increased by 200% compared to last year.

In 2021, we will use 264,000 tons of renewable raw materials worldwide, which is 25.5% of our total raw material usage.

We will further increase the ratio of renewable raw materials we have been using so far to reach our goal of more than 30% renewable raw material use by 2030.

We will also strive to solve environmental issues facing the earth through the search for and use of new renewable raw materials.

In addition to the use of recycled rubber, which we have been working on, we are expanding the use of a wide variety of renewable and recycled raw materials, such as silica made from plant-derived and inedible rice husks, resins derived from natural materials, and wires made by melting and reusing scrap iron.

The weight of conventional recycled rubber and non-petroleum-derived polymers used has increased by more than 110% compared to last year. The use of silica made from rice husks increased by 200% compared to last year.

In 2021, we will use 264,000 tons of renewable raw materials worldwide, which is 25.5% of our total raw material usage.

We will further increase the ratio of renewable raw materials we have been using so far to reach our goal of more than 30% renewable raw material use by 2030.

We will also strive to solve environmental issues facing the earth through the search for and use of new renewable raw materials.

Usage ratio of regenerated rubber in Tire products*1

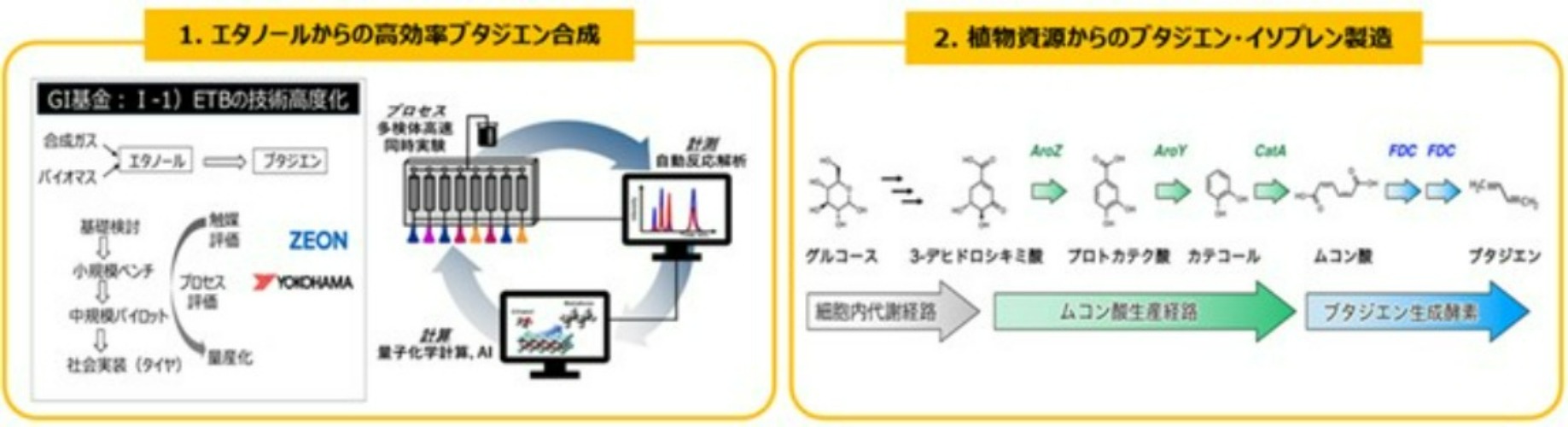

We are conducting joint research with the New Energy and Industrial Technology Development Organization (NEDO), the National Institute of Advanced Industrial Science and Technology (AIST), and the Advanced Materials and High-Speed Development Technology Research Association (ADMAT).

We have succeeded in mass synthesizing butadiene from bioethanol, producing a prototype automobile tire with the same performance as conventional tires, and demonstrating a series of processes.

Butadiene is currently produced from petroleum as an important chemical raw material for synthetic rubber, the main raw material for tires. The establishment of technology to produce tires from butadiene generated from biomass (biological resources) will promote CO2 reduction and sustainable raw material procurement by reducing dependence on petroleum.

We have succeeded in mass synthesizing butadiene from bioethanol, producing a prototype automobile tire with the same performance as conventional tires, and demonstrating a series of processes.

Butadiene is currently produced from petroleum as an important chemical raw material for synthetic rubber, the main raw material for tires. The establishment of technology to produce tires from butadiene generated from biomass (biological resources) will promote CO2 reduction and sustainable raw material procurement by reducing dependence on petroleum.

Prototype tire made with biomass-derived butadiene rubber

The prototype tire is the BluEarth-GT AE51 grand touring tire in size 185/60R15.

The cap tread and sidewalls of this tire were previously made from petroleum-derived rubber, but in this prototype tire, all petroleum-derived rubber has been replaced with bioethanol-derived butadiene rubber and natural rubber, so the rubber in both parts is composed entirely of sustainable rubber materials.

In addition, the prototype tire has the same material performance as when conventional petroleum-derived rubber was used.

ZEON Corporation and our company's "Development of Manufacturing Technology for Synthetic Rubber Core Chemicals with Carbon Resource Recycling" have been adopted by NEDO as a "Green Innovation Fund Project / Development of Manufacturing Technology for Plastic Raw Materials Using CO2, etc.".

The Green Innovation Fund Project is a program established by the Ministry of Economy, Trade and Industry (METI) to accelerate innovation through structural transformation of energy and industrial sectors and bold investment in order to achieve the national goal of "reducing overall greenhouse gas emissions to zero by 2050.

The program provides continuous support for 10 years to companies and others that address this goal as a management issue, from research and development and demonstration to social implementation.

This demonstration project aims to establish two advanced technologies to produce butadiene and isoprene, which are key synthetic rubber chemicals based on carbon resource recycling, from renewable carbon resources such as used tires and biomass at high yield rates, and to implement them in society in the 2030s.

This will contribute to the improvement of resource recycling and carbon neutrality in the tire and rubber industries.

The Green Innovation Fund Project is a program established by the Ministry of Economy, Trade and Industry (METI) to accelerate innovation through structural transformation of energy and industrial sectors and bold investment in order to achieve the national goal of "reducing overall greenhouse gas emissions to zero by 2050.

The program provides continuous support for 10 years to companies and others that address this goal as a management issue, from research and development and demonstration to social implementation.

This demonstration project aims to establish two advanced technologies to produce butadiene and isoprene, which are key synthetic rubber chemicals based on carbon resource recycling, from renewable carbon resources such as used tires and biomass at high yield rates, and to implement them in society in the 2030s.

This will contribute to the improvement of resource recycling and carbon neutrality in the tire and rubber industries.

Outline of the Project for Development and Demonstration of Carbon-Resource-Recirculating Synthetic Rubber Core Chemicals Manufacturing Technology

Recycling activities in the MB business

As with last year, recycled rubber is mainly used in the manufacturing of rubber belts for use with railway track ballast; with this ratio being 2.7% in fiscal year 2021.

In addition, we are working to promote the adoption of recycled carbon and rubber raw materials recycled from waste tires and other rubber waste.

The resin mold material (thermoplastic resin) used in hose manufacturing can be crushed and melted down again after use; however, in the past the powder generated in the crushing process has normally been discarded as waste. By introducing a two-stage crushing process, the crushed particles can be kept at a larger size in the first stage, controlling the generation of powder.

The powder generated in the next stage of the crushing process can be collected and reused with the same level of traceability as the larger crushed particles.

As a result, the recycling rate is now over 90%, and the annual usage of resin mold material has been reduced by 4.8 tons in 2020 and by 6.6 tons in 2021.

In addition, we are working to promote the adoption of recycled carbon and rubber raw materials recycled from waste tires and other rubber waste.

The resin mold material (thermoplastic resin) used in hose manufacturing can be crushed and melted down again after use; however, in the past the powder generated in the crushing process has normally been discarded as waste. By introducing a two-stage crushing process, the crushed particles can be kept at a larger size in the first stage, controlling the generation of powder.

The powder generated in the next stage of the crushing process can be collected and reused with the same level of traceability as the larger crushed particles.

As a result, the recycling rate is now over 90%, and the annual usage of resin mold material has been reduced by 4.8 tons in 2020 and by 6.6 tons in 2021.

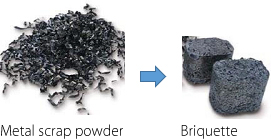

Yokohama Rubber Nagano Plant received the JEMAI Chairman's Award for metal scrap briquetting

We received the Japanese Environmental Management Association for Industry (JEMAI) Chairman’s Award for metal scrap (machining chip) briquetting at the Resource Recycling Technologies and Systems Awards in 2018.

The Nagano Plant manufactures joint fittings for hoses and assembles hoses and fittings. It has developed an effective system to contribute to resource recycling, in which the metal scrap powder generated during the production of metal fittings that had been sold to an external metal scrap supplier is briquetted for steel raw materials (solidified into a specific shape by hardening the powder with high pressure) for direct sales to steel companies.

The Nagano Plant manufactures joint fittings for hoses and assembles hoses and fittings. It has developed an effective system to contribute to resource recycling, in which the metal scrap powder generated during the production of metal fittings that had been sold to an external metal scrap supplier is briquetted for steel raw materials (solidified into a specific shape by hardening the powder with high pressure) for direct sales to steel companies.

Issues and Future

Improvement Measures

While using raw materials in business activities is unavoidable, our final goal is a state which minimizes the use of the Earth’s resources.

A key issue is correctly assessing whether the use of reusable products and recycled materials is leading to a reduction in the use of the Earth’s resources and the environmental impact, and to deploy these assessments on a global level.

A key issue is correctly assessing whether the use of reusable products and recycled materials is leading to a reduction in the use of the Earth’s resources and the environmental impact, and to deploy these assessments on a global level.