The Environment

Energy

KPI

Responsible Departments

Stance and Target

Review of FY 2021 Activities

Introduction of Initiatives

Issues and Future Improvement Measures

KPI

Move the screen to the left or right to see the table information

| Item | FY 2020 results | FY 2021 results |

|---|---|---|

| Total energy consumption |

(Consolidated) 1,678,571MWh * Crude oil equivalent: 424,376 KL |

(Consolidated) 1,858,043MWh * Crude oil equivalent: 469,625 KL |

| Total external energy consumption * Reported as Scope 3 (Other emissions) |

587,527,401 MWh | 726,027,203 MWh |

Responsible Departments

Each business location

- Activities are conducted by each business location, and the Global Warming Countermeasures Committee that the Environmental Protection Promotion Department serves as a secretariat for implements company-wide policy discussions and activities.

In 2022, the committee structure was revised and changed to the Carbon Neutrality Promotion Committee.

Stance and Target

Why is “Energy” a critical issue to be addressed?

Explanation of the reason and background

The Yokohama Rubber Group, which conducts production activities in 13 countries (Japan, United States, the Philippines, China, Thailand, Russia, Vietnam, India, Taiwan, Indonesia, Italy, Mexico and Israel) around the world, uses a large volume of energy in each business process. Because the reduction of energy consumption will lead to a response to the issue of climate change that is a problem on a global scale, the effective use of resources that are becoming depleted, and cost reductions, we have selected energy as a critical issue to be addressed.

Policies and stance relating to energy

The Yokohama Rubber Group has embodied our stance towards the environment in the Yokohama Rubber Environmental Policy and will work to minimize the burden on the environment by the provision of products and services in accordance with the Yokohama Rubber Group Action Guidelines. To this end, we take steps to realize sustainable, appropriate energy use and reduction of energy consumption throughout the value chain, starting from the design and manufacturing stage, by developing and adopting environmentally friendly technologies and working closely with everyone involved in the provision of related products and services.

We will conduct activities in an aim for the appropriate use and reduction of energy in accordance with international agreements concerning the proper use of energy, the regulations of countries where we conduct business (such as Japan’s Act on the Rational Use of Energy and Act on Promotion of Global Warming Countermeasures), and the policies of related organizations.

We will conduct activities in an aim for the appropriate use and reduction of energy in accordance with international agreements concerning the proper use of energy, the regulations of countries where we conduct business (such as Japan’s Act on the Rational Use of Energy and Act on Promotion of Global Warming Countermeasures), and the policies of related organizations.

Vision (attainment goal) / target

In line with the globally shared goal of achieving carbon neutrality by 2050, the Yokohama Rubber Group is working to reduce total greenhouse gas (GHG) emissions as an indicator for reducing energy consumption.

- Long-term target:

- Achieve net zero CO2 emissions (carbon neutrality) in our activities by 2050

- Mid-term target:

- Reduce CO2 emissions from company activities by 38% by 2030 compared to fiscal 2013

※This activity is the same level of effort as our goal of 28% reduction by 2030 (compared to 2019). - Encourage suppliers to collaborate with us in line with our targets.

- Reduce CO2 emissions from company activities by 38% by 2030 compared to fiscal 2013

Measures for vision achievement

We will implement the following measures aimed at promoting the appropriate use and reduction of energy throughout overall business activities.

- Promotion of a modal shift in logistics

- Management of energy in production

We will promote the effective use of energy through system improvements, savings improvements, process improvements, the development of management systems, the introduction of production systems, and the introduction of new energy (renewable energy) in the production process. - The Yokohama Group will establish seven energy-saving subcommittees under the supervision of the Global Warming Countermeasures Committee, and will promote energy reduction activities.

- We will promote the development and sales of eco-products in order to reduce the amount of energy use when products are used.

Review of FY 2021 Activities

System improvements (development of energy-saving vulcanization system, use of cogeneration), savings improvements (increased use of LEDs, improved equipment utilization), process improvements (optimization of rubber kneading process), and introduction of new energy (introduction of solar power generation system) were promoted.

Despite the increase in production in FY2021, Yokohama Rubber on a non-consolidated basis in Japan reduced GHG emissions by 19% compared to FY 2013.

Despite the increase in production in FY2021, Yokohama Rubber on a non-consolidated basis in Japan reduced GHG emissions by 19% compared to FY 2013.

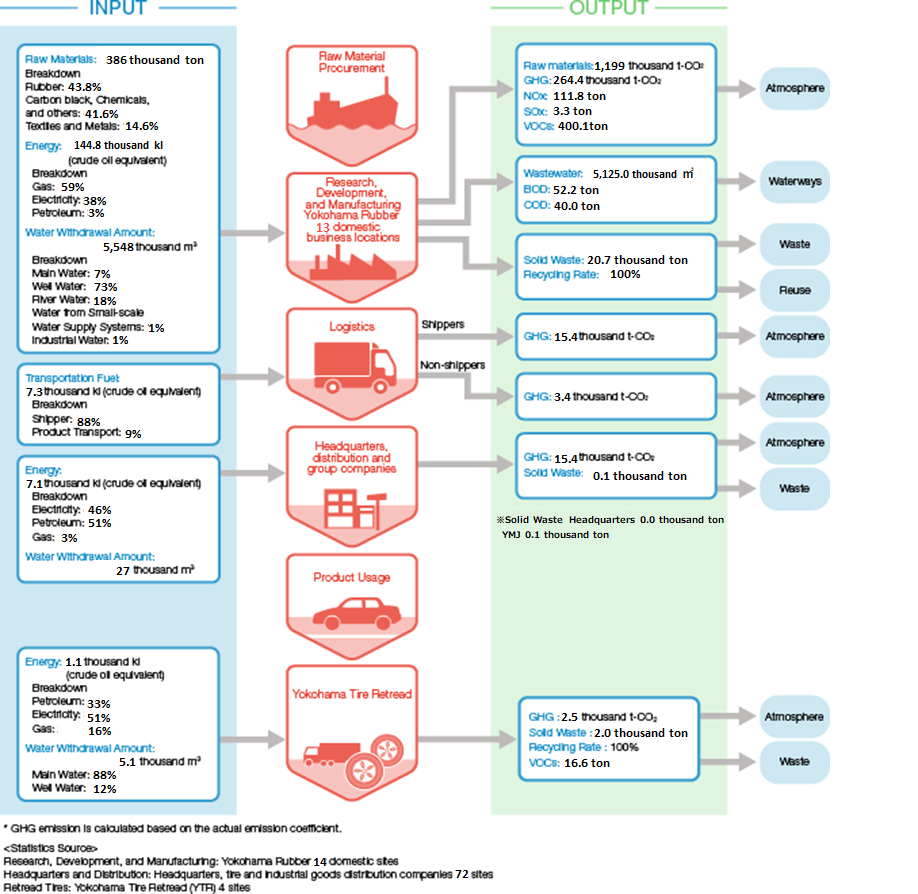

Overall picture of the environmental burden in Japan

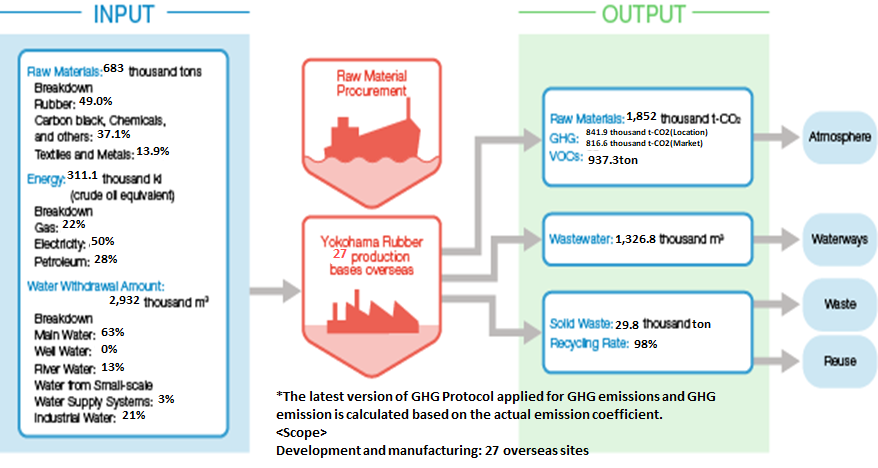

Overall picture of the environmental burden overseas

Introduction of Initiatives

Reduction of energy usage and CO2

- Target: Reduce CO2 emission by 25% by 2020 compared to the base year of 2006.

- Results: In logistics, we have been working to reduce CO2 emissions by 25% by 2020 from the base year of 2006.

In FY2020, we achieved the target with a 38% reduction compared to FY2006.

In FY2021, we continued to review transportation routes, reduce warehouse transportation volume, and improve loading efficiency, but emissions were 17,777t-CO2, up 2% from the previous year. On the other hand, the basic unit worsened by 3.3% to 44.2 kl/million ton-kilometer.

CO2 emissions and emissions per unit of output (from 2006)

* Yokohama Rubber on a non-consolidated basis

Rail transport for Shinshiro to Kyushu shipments

Energy management

- Visualization of energy

- Control of peak demand through demand control equipment

- Insulation of plant building roofs

- Reduction of boiler fuel by updating the water supply system of boiler facilities to reduce the boiler effluent rate.

*Installed an automatic control device for the number of air compressors in operation

Boiler facilities Water supply system

The agitation motor was changed from an air type to an electric type.

Air motor

Electric motor

Conducted steam drain trap diagnosis to control steam energy loss.

Steam drain trap (Upper photo: defective trap, lower photo: new trap)

Air leakage loss control by controlling (closing) the air source valve when not in operation.

Air valve management during non-operating hours (closed)

The heat insulation material is installed in the uninsulated part of the once-through boiler to control heat radiation loss.

Removable heat insulator

Air and steam leaks are detected using air leak visualization equipment at each plant in Japan to control increased losses due to air leaks.

Energy loss was improved by branching the piping system of steam-type unit heaters and adding individual valves after energy conservation diagnosis by the manufacturer.

Separated the steam system and installed a motor valve.

Full Operation of Co-generation Systems

At tire plants that use a large volume of energy and steam, it is possible to achieve a significant reduction in CO2 emissions through the adoption of co-generation systems that supply energy and steam at the same time. As of 2019, co-generation system had begun operation at three domestic plants. As a result of continuous 24-hour operations, 72% of the energy and nearly all of the steam used by these plants are now supplied by the co-generation systems, contributing to a reduction in CO2 emissions and a reduction in peak electric power consumption and in the overall amount of power purchased from the electric company. This was also adopted at the Thai Plant.

Mie Plant co-generation system

Mishima Plant co-generation system

Shinshiro Plant co-generation system

Thai Plant co-generation system

Improving the efficiency of production equipment motors and pumps

The pressure booster pumps for the pressure testers were changed to intermittent operation control and to air hydro pumps. In addition, the duct fan V-belt was replaced with an energy-saving type to reduce electricity consumption.

Air hydro pumps

The hydraulic unit for a multi-axis automatic lathe has been converted to an inverter to reduce power consumption during standby time.

Hydraulic unit inverter conversion

In addition, we are switching to high-efficiency motors.

High-efficiency motor

High-efficiency motor

Improving the efficiency of production equipment cooling-water pumps

In conjunction with the renewal of the calender equipment, the heat exchange system was changed from direct mixing to indirect heating to reduce the amount of steam used.

In winter, when the water temperature in the cooling water tank drops, the circulating cooling tower equipment is deactivated to reduce the amount of electricity used.

In winter, when the water temperature in the cooling water tank drops, the circulating cooling tower equipment is deactivated to reduce the amount of electricity used.

Cooling-water pump

Optimizing the chiller tank

Adoption of LED lights

We are replacing the ceiling lights (mercury and fluorescent) in our buildings in Japan and overseas with LED and high-efficiency ones to significantly reduce the power consumption of lighting. In addition, the use of motion sensor control has been promoted, which has been highly effective in reducing electricity consumption for lighting.

Conversion to motion sensors and LEDs

Conversion to motion sensors and LEDs

Mercury lighting → LED lighting

Replacement of lighting

Solar power generation

We are proceeding with the installation of environmentally friendly, renewable solar power generation facilities.

The facilities were adopted also in plants in India and China (Suzhou) in fiscal year 2017, and in the Philippines in fiscal year 2019.

The facilities were adopted also in plants in India and China (Suzhou) in fiscal year 2017, and in the Philippines in fiscal year 2019.

Solar power generation (Suzhou, China) installed capacity: 3,000 kw

Solar power generation (Hangzhou, China) installed capacity: 80 kw

Solar power generation (India) installed capacity: 200 kw

Solar power generation (Mie) installed capacity: 500 kw

Solar power generation (Philippines) installed capacity: 4,000 kw

Biogas

Food waste was going to landfill at the Tirunelveli plant in India. The problem was hygiene and the generation of methane, which has an emission factor 25 times higher than that of CO2. Therefore, we built a biogas plant and processed 250 kg of food waste per day to generate gas. Therefore, we built a biogas plant and processed 250 kg of food waste per day to generate gas in 2019. In 2021, LPG gas consumption was reduced by 559 kg, resulting in a reduction of 1.68 t-CO2.

Energy Saving Month activities

Based on the vision of “Connect everyone’s wisdom and ingenuity, start winter energy saving on your own,” we shared awareness of the significance energy saving to “strengthen corporate competitiveness through cost reductions, respond to fossil fuel depletion, reduce the burden on the global environment, and have corporate social responsibility,” and made preparations for the practice; thereby during the energy-saving month of February, significant results were achieved through the accumulation of multiple small efforts, thanks to effective coordination between the production department, equipment maintenance department, and administration department at plants. For example, the maintenance department conducted an energy saving audit, inspected and found steam and air leaks, and made repairs.

Education activities during the Energy Saving Month

Leakage inspection and visualization

Leak repair

Energy saving subcommittee

Energy saving subcommittees are held by energy saving staff from domestic plants to follow up on annual energy saving reduction plans, investment in energy-saving equipment, and progress.

The committee introduces and horizontally deploys examples of improvements at each plant, which has been effective in reducing energy consumption.

The committee introduces and horizontally deploys examples of improvements at each plant, which has been effective in reducing energy consumption.

Activities of the Energy Saving Subcommittee

Activities of the Energy Saving Subcommittee

Activities to strengthen energy management based on guidance from consultants.

We are strengthening energy guidance through means such as reductions in energy loss in line with production variation (switching equipment on and off), representing the adoption of a just-in-time system for energy.

Issues and Future

Improvement Measures

We will have reductions in total energy use as we plan to continue expanding the introduction of cogeneration systems.

With the aim of increasing the renewable energy usage ratio, we plan to expand the introduction of solar power generation, etc. in order to increase the percentage of our business locations that use renewable energy.

With the aim of increasing the renewable energy usage ratio, we plan to expand the introduction of solar power generation, etc. in order to increase the percentage of our business locations that use renewable energy.