Basic technologies to support the future development of products and services at Yokohama Rubber

Computational ScienceAeroacoustic simulation

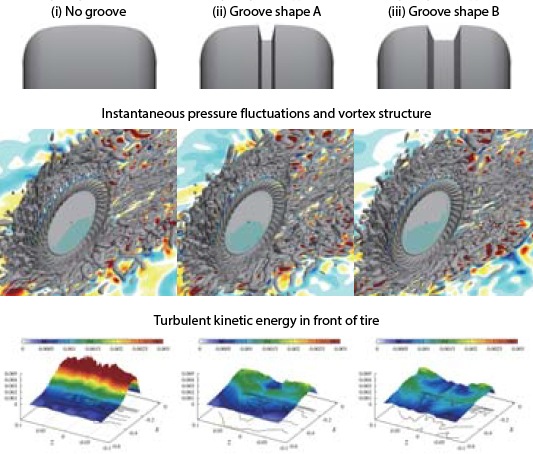

The reduction of tire noise is an important environmental issue. As the disruption of the flow of air around tires and the road surface is one of the main causes of tire noise, we are engaged in research related to direct simulations of air vortex flow structure around tires and the resulting acoustic waves.

In 2014, Yokohama Rubber succeeded in becoming the first in the world to have a precise simulation of the vortex structure and acoustic waves around tires when running.

In 2015, the theme was selected as an HPCI (High Performance Computing Infrastructure) research topic, and the impact of the differences in the depth, width, etc. of grooves on the tire surface on acoustic waves (noise) was clarified.

This has been helpful in the design of tread patterns and facilitated the development of low noise tires.

Analysis3D structural analysis of tire steel cord / rubber adhesion surfaces

Steel cords are embedded in tires to improve durability. The adhesion between these steel cords and the rubber that covers them is important for safety.

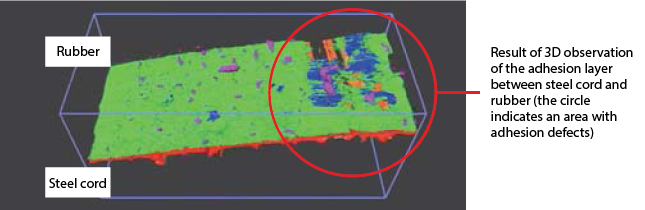

We have utilized electron microscope technology to become the first in the world to visualize the adhesion layer between steel cord and rubber surfaces in 3D (see diagram).

Some separated areas and/or spaces were discovered in the adhesion layer in the rubber and metal adhesive interface for the wire sample after humidity aging.

The adhesive force between steel cord and rubber is weak in these areas, and can be inferred that this is a source of declines in adhesiveness. Going forward we will further clarify the adhesion mechanism and apply this knowledge to the development of more durable tires.