A fire broke out on May 14, 2017 at the tire plant at Yokohama Tire Philippines, Inc. (YTPI). We would like to again offer our sincerest

apologies to the customers, the local community, and various other affected parties for the inconvenience and concern caused by the fire’s

outbreak and aftermath.

The Group will work company-wide to steadily implement fundamental fire prevention measures to ensure that a similar incident does

not occur in the future.

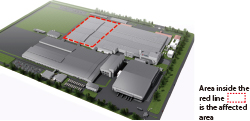

Overview of the fire

| Time of outbreak | Around 15:00 local time on May 14; completely extinguished around 23:00 |

|---|---|

| Fire stricken area | Approximately 17,400 m2 in north-east area of east plant |

| Details of fire | Buildings and production facilities partially damaged, products in warehouse destroyed in fire 2 people injured in fire extinguishing activities |

Fire Recurrence Prevention Measures

The company will verify all of the potential fire causes, and take fundamental measures against them. Furthermore, we will develop mechanisms that enable faster fire detection and extinction, and deploy them in production sites all over the world. We will then repeat inspection on firefighting equipment and fire drills as we work to ensure that a similar fire does not occur again.

Fire drills

Rescue training for injured people

Strengthening Safety Efforts

Although we have conducted various safety initiatives in an aim for the

creation of a safe and ideal working environment and good health, we

have currently not achieved zero work-related accidents.

In response to this situation, we have conducted overall inspections

on equipment at all production sites in Japan and overseas as a

countermeasure to discover risks that could cause disasters, such as

areas where people could become pinched by or caught in machinery

or areas where people could fall. The management has been

proactively involved in these overall inspections, and efforts are being

made to thoroughly identify and improve all dangerous equipment

based on strong leadership.

We are also expanding risk sensitivity drills to enhance sensitivity to

risks so that employees can detect risks in advance and respond to

them.

Risk sensitivity drills

In addition, we are working to “instill safety awareness through grassroots corporate culture and spirit reform” to develop people capable of working safely and creating a safe workplace. As part of day-to-day efforts to improve the safety awareness, we distribute safety goods and repeat safety slogans with all employees before work.

Distribution of safety straps

Repeating safety slogans

Details of main efforts to strengthen risk sensitivity drills

- Expand contents of drills: Increase in types of and learning materials for risk sensitivity drills at locations including the Mishima Plant and YTMT* (improvement in quality)

- Increase the number of times drills are held

- Expand locations where drills are held: Drills have been established at all major plants in Japan and overseas, considering expansion

* Yokohama Tire Manufacturing (Thailand) Co., Ltd.

Expected effects

- Honing sensitivity to various types of risks

- Maintain and improve risk sensitivity