YOKOHAMA fabric conveyor belts have been supplied to a wide range of applications. From mine to port, power plants to cement, chemicals, fertilizers and agribusiness, the performance is proven in many different industries.

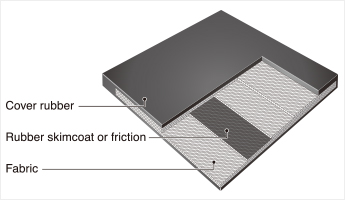

General Fabric Belt

Features and Benefits

■Wide Selection of Belt Strengths

Available belt strengths ranges from 100N/mm up to 2,500N/mm covering a variety of applications.

■Cover Compounds and Cover Gauges

Most of YOKOHAMA’s original high performance cover compounds are available with wide range of cover gauges.

■Excellent Durability

Superior resistance to bending fatigue and outstanding rubber adhesion to fabric realize longer service life.

■Perfect Load Support

Ensure maximum conveying capacity.

■Reliable Vulcanized Splices

Hot vulcanized splice is recommended. YOKOHAMA offers industry proven splice technology.

Belt Selection

Carcasses ; Nylon/Nylon (NN) and Polyester/Nylon (EP)

Belt strength ; from 100N/mm to 2,500N/mm

Belt width ; 300mm - 2,400mm

Please consult with your local YOKOHAMA sales representative for more belt strength and size availability.

MJ-Fabric Conveyor Belt

Features and Benefits

■Excellent Fastner Holding

YOKOHAMA’s original carcass design allows outstanding fastner holding.

■Easy and Quick Installation

Eliminate long vulcanizing time and complex splice process.

■Easy Maintenance

■Excellent Flexibility

Applicable to conveyor with smaller pulleys.

YOKOHAMA MJ Conveyor Belt Data

| GRADES |

150 |

220 |

330 |

440 |

550 |

| CONSTRUCTION |

MJ-75 X 2P |

MJ-110 X 2P |

MJ-110 X 3P |

MJ-110 X 4P |

MJ-110 X 5P |

TENSTION RATING

VULCANIZED AND

FASTENER |

(N/mm)

(lbs/in) |

25

150 |

40

220 |

60

330 |

80

440 |

95

550 |

APPROX. BELT

THICKNESS

(1/8” X 1/16” COVERS) |

(mm)

(in) |

8.1

0.319 |

8.0

0.315 |

9.7

0.382 |

11.7

0.461 |

13.7

0.539 |

APPROX BELT

WEIGHT

(1/8” X 1/16” COVERS) |

(kg/m2)

(lbs/ft2) |

9.3

1.9 |

9.2

1.9 |

11.2

2.3 |

13.5

2.8 |

15.8

3.2 |

MIN. WIDTH

FOR TROUGHING EMPTY

35° IDLERS |

(mm)

(in) |

400

16 |

450

18 |

600

24 |

750

30 |

900

36 |

MAX. WIDTH ON 35°

IDLERS FULLY LOADED

WITH 100# MATERIAL |

(mm)

(in) |

750

30 |

900

36 |

1200

48 |

1500

60 |

1800

72 |

RECOMMENDED

MIN. PULLEY

DIAMETERS |

OVER

80%

TENSION |

(mm)

(in) |

400

16 |

450

18 |

600

24 |

750

30 |

900

36 |

OVER

60 TO 80%

TENSION |

(mm)

(in) |

350

14 |

400

16 |

500

20 |

600

24 |

750

30 |

OVER

40 TO 60%

TENSION |

(mm)

(in) |

300

12 |

350

14 |

400

16 |

500

20 |

600

24 |

TO 40%

TENSION |

(mm)

(in) |

250

10 |

300

12 |

350

14 |

450

18 |

500

20 |

TAIL &

SNUB |

(mm)

(in) |

| RECOMMENDED FASTENERS |

FLEXCO #140

FLEXCO R5 |

FLEXCO #190

FLEXCO R5 |

FLEXCO #140

FLEXCO R5 |

FLEXCO #190

FLEXCO R6 |

FLEXCO #2

FLEXCO R6 |

RECOMMENDED TAKE-UP SPACE

AS % OF CENTER DISTANCE |

MIN. 1.5% FOR POLYESTER AND MIN. 2.4% FOR NYLON (MIN. 500 MM OR 2 ’) |

Protex

Discover the PROTEX difference today

Because you deserve better performance from your investment!

Problem

Does your portable crushing and other high abuse equipment suffer from product entrapment that punctures your expensive belts resulting in costly repairs or premature belt replacement? Excessive cover abrasion? Premature gouging and wear?

Solution

Yokohama PROTEX with UR Covers. Designed to be virtually “Maintenance Free” belts for portable quarry crushing and other high abuse equipment, PROTEX belts give you greater peace-of mind with the lowest cost per tonnage and best ROI on the market today.

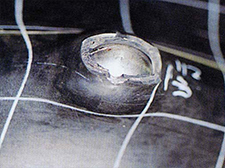

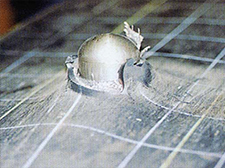

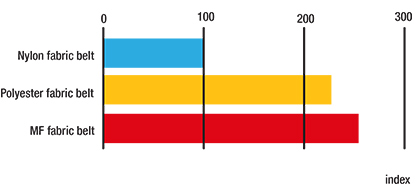

Trapped Material Test

Nylon Fabric Belt

630 2Ply 8x3mm covers

Polyester Fabric Belt

630 2Ply 8x3mm covers

PROTEX

630 2Ply 8x3mm covers

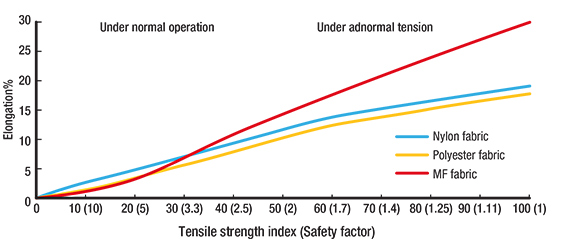

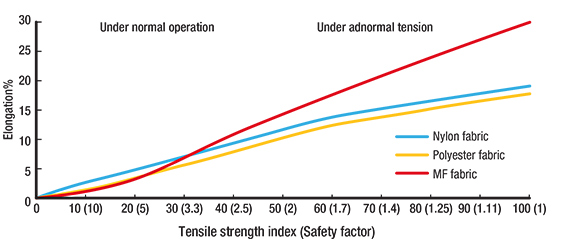

Yokohama PROTEX features a special polyester fabric with elongation at break 1.8 times higher than Nylon fabric. Nevertheless, belt stretch under operating tension is less than that of conventional polyester fabric belts.

Comparison of belt stretch at normal & abnormal operation

|

PERMANENT ELONGATION |

TAKE-UP TRAVEL |

| NYLON FABRIC: |

1.3 - 1.8% |

over 2.4% |

| CONVENTIONAL POLYESTER: |

0.5 - 1.0% |

over 1.5% |

| PROTEX: |

0.5 - 0.7% |

over 1.0% |

Yokohama PROTEX belts with UR Covers

UR covers were initially developed by Yokohama to handle heavy limestone rock before and after primary crushers. UR cover belts have succeeded in improving belt life with superior impact and gouge resistance features superior to that of RMA-1 cover belts.

Comparison of impact resistance with UR covers

PROTEX belt absorbs impact like no other belts.

PROTEX BELTS = TOUGH, FLEXIBLE, AND LOW-STRETCH

- Excellent resistance against trapped material & cake build-up on pulleys

- Excellent impact resistance and cut & gouge resistance

- Superior abrasion & wear resistance under extreme conditions

- Less permanent elongation & belt stretch

- Best choice in rough operating conditions. ie Portable Cone & Jaw Crushers

Let us show you how Yokohama PROTEX belts can take the abuse & deliver!

BELT SELECTION:

BELT

STRENGTH |

NO.

OF

PLIES |

COVER

RUBBER

THICKNESS |

BELT WIDTH |

BELT

THICKNESS |

LENGTH

/R |

| (N/MM) |

500 |

600 |

700 |

750 |

800 |

900 |

1000 |

1050 |

1200 |

1400 |

| 500 |

2 |

6.0 x 3.0 |

|

* |

|

* |

|

* |

* |

* |

* |

|

12.4 |

200 |

| 630 |

2 |

8.0 x 3.0 |

|

|

|

|

|

* |

|

* |

* |

* |

15.1 |

200 |

*Belt strength such as 1000/4 and 1250/4 for large lump material transportation or other than above specifications are available.