Heavy Duty Compounds Belt

Yokohama Original Compound

| COMPOUNDS |

FEATURES |

Abrasion

Resistance |

Impact

Resistance |

Cold

Resistance |

| SWR |

High abrasion resistance |

AA |

A |

A |

| UWR |

Ultimate abrasion resistance |

AAA+ |

A |

A |

| UR |

Impact resistant for heavy ore and high chutes |

AA |

AAA |

A |

| IceGuard AR |

High impact and abrasion resistance under extreme low temperature |

A |

AA |

AAA |

International Standards

- RMA Grade I, II

- DIN-X, Y, W, Z, X

- AS-A, M, M+, N, F

- JIS-H, S, L, A, G, P, D

- BS/IS-M24, N17

Energy Saving Belt

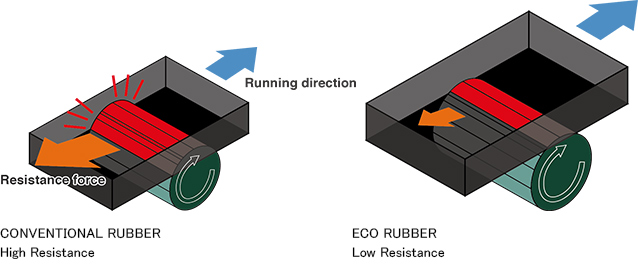

YOKOHAMA has developed Energy Saving Conveyor Belt, which extends the advantages of conveyor belts, allowing reduced power consumption and reduced operational cost of the conveyors with innovative and highly engineered cover compound technology.

Features and Benefits

■Remarkably Reduce Energy Consumption

Specially developed high elasticity compound reduces energy loss.

Side-by-side comparison of power consumption with Conventional & Energy Saving Conveyor Belt

| Customer |

Cement Company |

| Belt Spec |

ST-1400 900mmx6.0mmx5.0mm |

| Length of Conveyor |

7,741m |

| Lift |

140.4 (declined) |

| Carried Material |

Limestone (1,500t/hr) |

| Belt Speed |

200m/min. |

| Drive System |

300kW x2 |

Conventional

YOKOHAMA EcoReduction: 28.6%

■Environmentally Friendly

Less energy consumption enables you to reduce CO2 emission.

■Economically Efficient

Substantial savings in power consumption when continuously operated. Such savings in power consumption can yield additional returns to the plant.

■Downsizing Motors and Pulleys

Belt strength may be decreased up to 20%, which could allow customers to design smaller motors when installing a new conveyor.

Heat Resistant Belt

For decades, plants like yours hve been forced to cope with belts that quickly crack and blister resulting premature failure, splice failure and carry-back, finally, a new bread of belt is changing all that. YOKOHAMA breakthroughs in heat tolerance, abrasion resistance and splice adhesion properties have been industry-proven throughout the world in cement plants,lime kilns, potash, foundries, coke oven plants, iron ore pelletizing, steel plants and others.

Available Compounds

|

TYPE |

TEMPERATURE

RANGE OF

MATERIALS |

BELT SURFACE

TEMPERATURE

RANGE |

LOW-MEDIUM

TEMPERATURES |

Hamaheat®

#2110 |

Lumpy Materials:

70-200℃

Powdery Materials:

70-150℃ |

60-120℃ |

HIGH

TEMPERATURES |

Hamaheat

Super 50 |

100-400℃ |

60-200℃ |

Hamaheat

Super100 |

Available carcass, belt strength and width vary depending on the cover compounds. Please consult with your local YOKOHAMA sales representative for your belting needs.

Applications

- Sinter

- Coke Oven

- Cement

- Chemical

- Foundries

- Cement Clinker

- Burnt Lime

- Potash

- Iron Ore Pellet

- High Temperature Powdery Materials

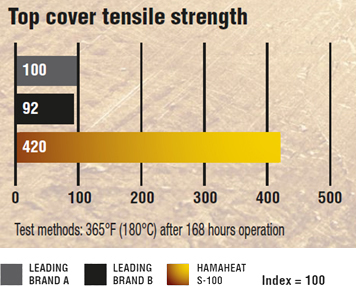

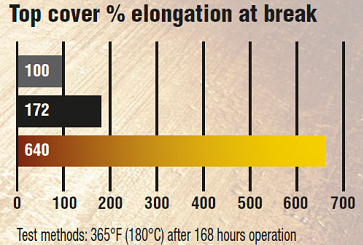

Featured Product: Hamaheat Super-100

■Extreme heat resistance

Advanced construction withstands heat up to 750 deg F (400 deg C).

- Specially designed polymer resist hardening and cracking

- Reduces costs associated with carry-back material and clean-up.

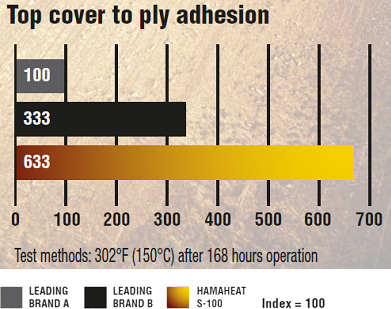

Side-by-side comparison

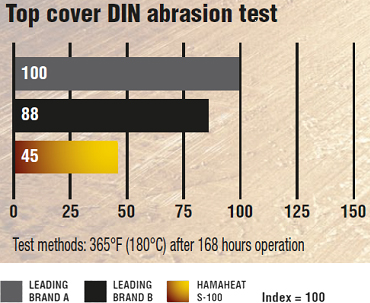

■Superior abrasion resistance under extreme conditions

- Significantly less cover loss in DIN abrasion tests

- Lowest cost-per-tonnage and the best ROI

Side-by-side comparison

■Extreme-heat carcass design

- Proprietary fabric and dipping process

- Ensures splice integrity and resistance to flexural fatigue.

Side-by-side comparison

Non-Stick Belt

Carry-back could cause so many issues with your plants.YOKOHAMA’s Non-stick conveyor belts feature a specially developed compound containing a lubricating agent that reduces the carry-back associated with a standard belt.

The anti-adhesive performance will last for the life of the belt and promote a clean environment and efficient operation of your facilities.

Available Compounds

Choose from Non-stick, Heat Resistant Non-stick and Super Non-stick belts to find the most suitable belt for your application. Use of belt cleaner is recommended in order to maximize the benefits of non-stick belts.

Super Non-Stick

Improved build-up resistance with special resin material.

Heat Resistant Non-Stick

Non-stick with excellent heat resistance (300F).

Non-Stick

Compound with lubricant agent minimizes build-up.

Applications

- Clay, Gypsum, Dolomite and any other conveyors carrying

- other powdery and/or wet materials.

Features and Benefits

■Outstanding Performance in Reducing Carry-Back

YOKOHAMA’s non-stick belts are ideal when needing to carry powdery and moist materials. Its special lubricating agent prevents materials from adhering on the belt surface thereby reducing the amount of carry-back remarkably.

■Performance Lasts for the Life of the Belt

Since the lubricating agent is not coated on the top of the belt surface but mixed with other polymers, the anti-adhesive performance will last for the life of the belt.

■Superior Abrasions Resistance

YOKOHAMA’s non-stick belt has superior abrasions resistance that allows combined use of a belt cleaner.

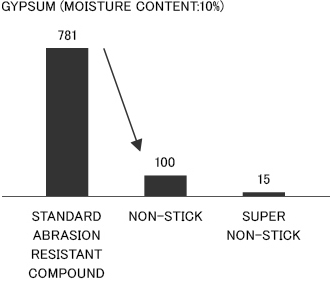

■Abrasion Resistance (Din Wear Test)

Lower Facility Maintenance Costs

Since the carry-back is reduced by using the Yokohama non-stick belts, your facility will stay cleaner and your maintenance costs will be less.

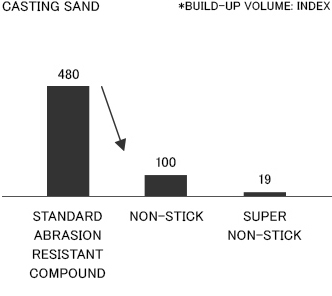

■Build up volume test

Our laboratory tests shows the remarkable reduction in build-up for some of the powdery materials.

■To maximize the benefits of Non-Stick belts

Material build-up volume changes depending on material temperature and moisture content.

It is highly recommended to use belt cleaners to maximize the performance of Non-Stick belts.

Oil Resistant Belt

YOKOHAMA’s superior oil resistant belts is designed to withstand the maximum degree of oil resistance for various applications and industries.

Applications

- Plants Carrying Parts and Components Coated with Machine Oil

- Heavy Oil Treated Coal in Coking Plants

- Electric Power Generating Plants

Available Cover Compounds

| TYPE |

WORKING TEMPERATURE |

TYPE (NAME) OF OIL |

| 200 |

-20 to 100℃ |

palm oil, lard, fish oil, soybean oil, sesame oil, cottonseed oil, tempura cooking oil, oily sewage, human waste, grease, anti-rust oil, roller oil, machine oil, light oil |

| 300 |

-20 to 65℃ |

type A heavy oil, type B heavy oil type C heavy oil, Valvolin oil, waste products from heat-treatment |

Flame Resistant Belt

With advanced technology in flame resistant polymer, YOKOHAMA offers a wide selection of compounds which meet most of the international standards.

Features

■International Standard

Compliant with the following International standards

- ISO

- DIN

- AS

- MSHA 2G

- CSA

- JIS

Best Selection

Please consult with your local YOKOHAMA

representative for the details.